Badem soyma makinesi, manuel hareket için yüksek kaliteli saf kauçuk yumuşak rulo kullanır. Badem kırmızı derisi bu makine ile kolayca çıkarılır. Bu badem soyucu makine, yer fıstığı, bakla gibi çeşitli malzemeler için uygundur. Badem soyma makinelerinin soyma oranı 'e kadar çıkar. Kırma oranı hasar olmadan %5'in altındadır. Badem yer fıstığı işleme pazarında nispeten gelişmiş bir badem/yer fıstığı soyucu ekipmanıdır. Ham maddeyi soyarken, deriyi yıkamak için biraz su eklemek gerekir. Bu nedenle ıslak yer fıstığı soyma makinesi, bakla soyma makinesi olarak da bilinir.

Otomatik badem soyma ekipmanı çalışma prensibi:

Badem/fıstık soyma makinesi, badem kırmızısı kabuğunu çıkarmak için özel bir ekipmandır.

1. Soyulmadan önce ham maddelerin sıcak suya batırılması gerekir. Farklı malzemelerin farklı ıslatma süresine ve ıslatma sıcaklığına ihtiyacı vardır.

2. Islatılmış bademleri hazneye dökün. Hammadde, üç güçlü silindirle sabitlenen dönen bir lastik tekerleğe titreştirilir.

3. Daha sonra soyma etkisi, indükleyici şerit, besleme tekerleği ve Taklit elle döndürme ile elde edilir.

4. Daha sonra boşaltma çarkı soyulmuş bademi hazneye bastırır ve boşaltma hunisine boşaltır ve badem kabuğu süet çarkından dışarı çekilir.

Badem/fıstık soyma makinesi, diferansiyel yuvarlanma sürtünme iletimi prensibini kullanır. Bademlerin nem oranı yüzde beşten az olduğunda (aşırı kızarmayı önlemek için) yer fıstığının soyulması. Badem elekten geçirildikten sonra havalandırma sistemi kabuğu emer.

Islak fıstık soyma makinesi özellikleri:

1. Yer fıstığı soyma makinesi ıslak soyma işlemini benimser, bu nedenle kırılma oranı düşüktür ve soyulmuş badem üstün kaliteye sahiptir.

2. Yer fıstığı soyulduktan sonra bademlerin yüzey rengi değişmez, protein kaybı olmaz.

3. Bademin soyulma işlemi sırasında kabuğu ve kuruyemişleri otomatik olarak ayrılarak boşaltılabilir.

4. Makine küçük boyut, düşük enerji tüketimi, yüksek verimlilik ve kolay kullanım avantajlarına sahiptir.

5. Fıstık soyma makinesi istikrarlı performans, güvenlik ve güvenilirlik, yüksek verimlilik, iyi soyma etkisi ve düşük yarı tane oranı avantajlarına sahiptir.

Farklı hammadde ıslatma süresi:

Yer fıstığı için ıslatma süresi yaklaşık 3-5 dakikaya ihtiyaç duyar, ıslatma sıcaklığı yaklaşık 80°C'nin üzerinde olmalıdır

Badem hakkında, ıslatma süresi yaklaşık 15 dakikaya ihtiyaç duyar, ıslatma sıcaklığı yaklaşık 80°C'nin üzerinde olmalıdır

Bakla için ıslatma süresi yaklaşık 20 dakikaya ihtiyaç duyar, ıslatma sıcaklığı yaklaşık 80°C'nin üzerinde olmalıdır

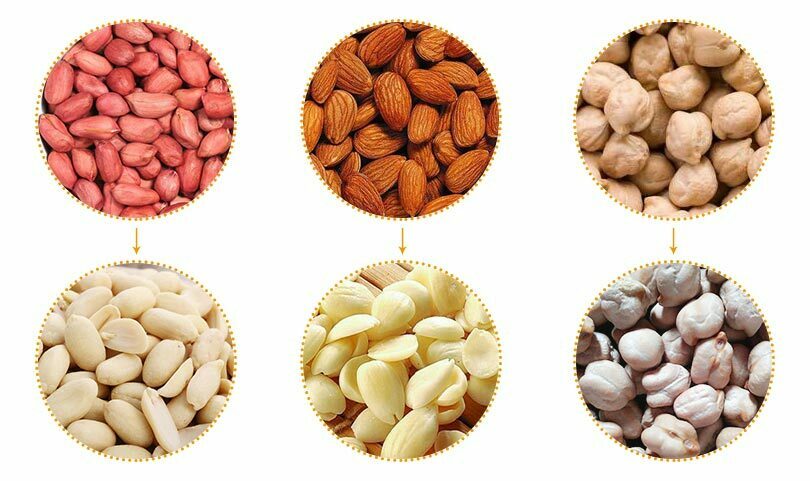

Somun soyma makinesi uygulaması:

Badem: Badem soyma makinesi esas olarak ıslatılmış bademleri soyma makinesi haznesine döker. Peeling önlüğü aracılığıyla cilt soyuluyor, cilt otomatik olarak ayrıştırılıyor ve ayırma cihazı aracılığıyla dışarı atılıyor. Soyulmuş badem esas olarak bademlerin ilk işlenmesinde veya konserve bademlerin, bademli içeceklerin, badem çiğinin vb. işlenmesinde kullanılır.

Yer Fıstığı: Soyulmuş Yer Fıstığı, kızarmış yer fıstığı, çok aromalı yer fıstığı, yer fıstığı şekeri, yer fıstığı sütü, yer fıstığı protein tozu ve sekiz hazineli yulaf lapasının işlenmesinde yaygın olarak kullanılır.

Beyaz barbunya fasulyesi: Beyaz barbunya fasulyesi ürünlerinin erken döneminde beyaz barbunya fasulyesinin soyulma tedavisinde yaygın olarak kullanılmaktadır. Makine sağlam, güvenli, kullanımı kolay ve verimli olacak şekilde tasarlanmıştır.