سموسے بنانے والی مشین ایک ایسی مشین ہے جو خود بخود سموسے تیار کرتی ہے۔ یہ ایک مشین ہے جو خاص طور پر سموسوں کی خصوصیات کی بنیاد پر تیار کی گئی ہے۔ خودکار سموسے مشین خودکار نوڈل فیڈنگ، فلنگ، فلنگ وغیرہ کے مراحل کو محسوس کر سکتی ہے۔ تیار کردہ سموسوں میں کافی فلنگ اور اچھی شکلیں ہوتی ہیں۔ اور بھرنے، آٹے کی موٹائی، اور پیداوار کی رفتار کو ایڈجسٹ کیا جا سکتا ہے.

سالن پف بنانے والی مشین کا اطلاق

کری پف مشین کے ہیڈ مولڈ کو تبدیل کیا جاسکتا ہے، لہذا یہ مختلف قسم کے کھانے تیار کرسکتا ہے۔ جیسے اسپرنگ رولز، ونٹنز، راویولی، کری پف، ایمپاناڈا، ڈمپلنگ، پیروگی، گیوزا، کالزون اور دیگر کھانے۔

سموسے بنانے والی مشین کی ساختی خصوصیات

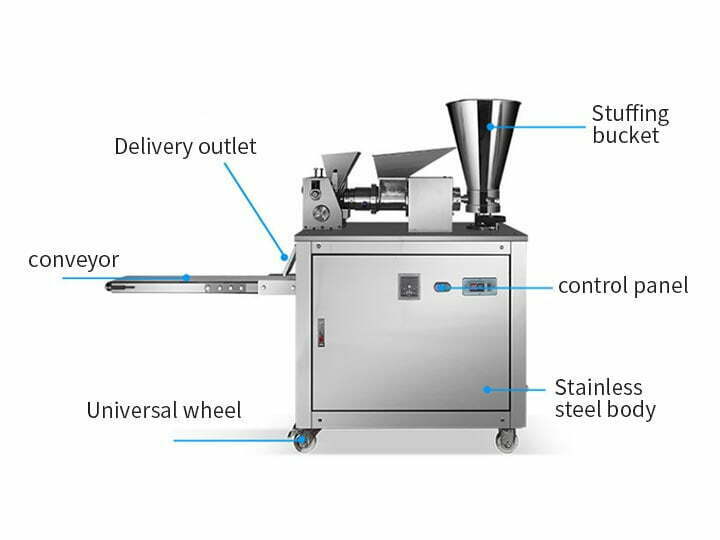

کمرشل سموسے بنانے والی مشین میں اسٹفنگ بالٹی، کنٹرول پینل، ریک، کنویئر بیلٹ، کنویئنگ آؤٹ لیٹ اور دیگر پرزے شامل ہیں۔

سموسے بنانے والی مشین کے سر پر مولڈ کو گاہک کی پیداواری ضروریات کے مطابق بنایا جا سکتا ہے۔ لہذا، مشین مختلف اشکال کی مصنوعات تیار کرنے کے لیے سانچوں کی جگہ لے سکتی ہے۔

فلنگ ایکسٹروژن ہیڈ کے ذریعے باہر نکلتی ہے، اور بھرنے کی مقدار کو ایڈجسٹ کیا جا سکتا ہے۔

یہ سموسے مشین کی نوڈل بالٹی ہے، جو آٹا رکھنے کے لیے استعمال ہوتی ہے۔ کام کرتے وقت، آٹا ہاپر اور بھرنے کو ایک ہی وقت میں نکالا جاتا ہے، اور باہر نکالے ہوئے آٹے کی مقدار اور رفتار کو بھی ایڈجسٹ کیا جا سکتا ہے۔

تجارتی سالن پف مشین سالن کیسے تیار کرتی ہے؟

تجارتی خودکار کری پف مشین ایک ہی بار میں سموسوں کی تیاری مکمل کر سکتی ہے۔ یہ بنیادی طور پر ہاتھ سے سالن سموسے بنانے کے اقدامات کی نقل کرتا ہے۔ تیار شدہ فلنگ اور ملا ہوا آٹا بالترتیب فلنگ بالٹی اور آٹے کی بالٹی میں ڈالیں۔ مشین کے اتارنے کی مقدار اور رفتار کو ایڈجسٹ کریں۔ شروع کرنے کے بعد، مشین سیٹ پروگرام کے مطابق خود بخود ان لوڈ، بھرنے اور لپیٹے گی۔ تیار کری سموسہ ڈیلیوری ایگزٹ سے پہنچایا جاتا ہے۔

تجارتی سموسے بنانے والے کی خصوصیات

- سموسے بنانے والی مشین ذہین کنٹرول پینل آپریشن، سادہ آپریشن اور اعلیٰ درستگی کو اپناتی ہے۔

- یہ مشین ہاتھ سے کریلے سموسے بنانے کے مراحل کی نقل کرتی ہے۔ ڈبل کنٹرول دو طرفہ مقداری خوراک کے اصول کا استعمال کرتے ہوئے، مشین میں صرف بھرنے اور آٹا رکھا جاتا ہے، اور مشین سموسوں کی پیداوار کو مکمل کر سکتی ہے۔

- بھرنے اور آٹا کاٹنے کی مقدار اور رفتار کو کنٹرول پینل کے ذریعے ایڈجسٹ کیا جا سکتا ہے۔

- ایک مشین جس میں ایک سے زیادہ افعال ہوتے ہیں، مختلف مولڈنگ ڈیز کو تبدیل کر کے مختلف پروڈکٹس بناتے ہیں۔ جیسے اسپرنگ رولز، ونٹنز، راویولی، کری پف، ایمپاناڈا، ڈمپلنگ، پیروگی، گیوزا، کالزون اور دیگر کھانے۔

- پہنچانے والی سطح اور تشکیل دینے والے حصے کم مزاحمت، اچھی تشکیل، اور آسانی سے جدا کرنے، اسمبلی اور صفائی کے ساتھ، خصوصی اینٹی چپکنے والی ٹیکنالوجی کے مواد کو اپناتے ہیں۔

سموسے بنانے والی مشین کے پیرامیٹرز

| ماڈل | TZ-80 |

| صلاحیت | 4800pcs/h |

| سموسے کا وزن | 14-18 گرام |

| وولٹیج | 220v |

| طاقت | 2.2 کلو واٹ |

| مواد | سٹینلیس سٹیل |

| وزن | 110 کلوگرام |

| سائز | 0.66*0.435*0.77m |

تبادلۂ خیال شامل کریں