Distribusi produksi permen karamel digunakan untuk menghasilkan camilan karamel, menggunakan sistem operasi PLC untuk mewujudkan otomatisasi penuh. Ini mampu memberi bahan baku secara terus-menerus, meratakan, memotong melintang, dan memotong silang. Selain itu, kepadatan level dapat disesuaikan, dan ketebalan produk merata. Dengan penyesuaian konversi frekuensi, ukuran potongannya akurat dan bentuknya baik.

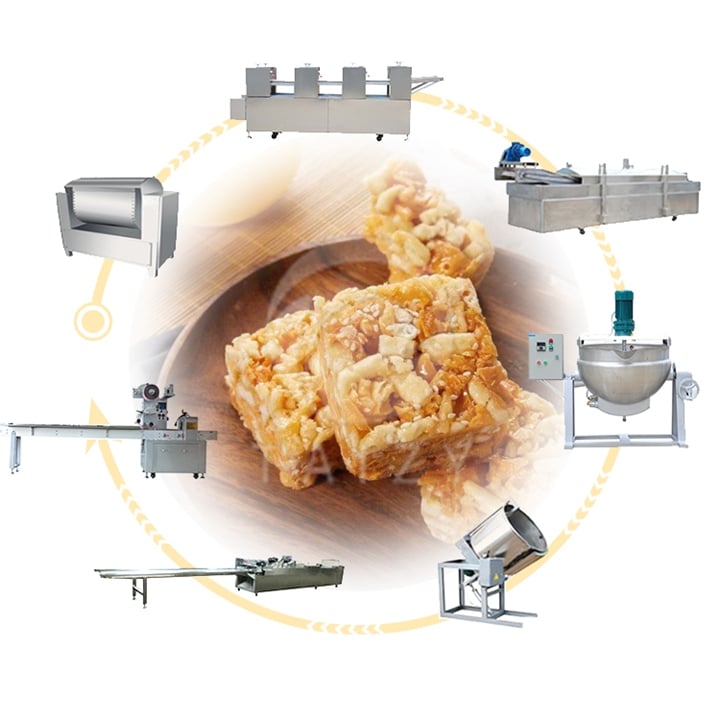

Seluruh lini produksi suguhan karamel diproduksi secara terus menerus, dan tidak diperlukan sambungan manual dalam prosesnya, yang sepenuhnya mewujudkan pengoperasian otomatis dan cerdas. Lini produksi suguhan karamel membutuhkan tujuh mesin, yaitu mesin pengaduk adonan, mesin pengepres adonan, mesin penggorengan minyak, panci masak gula, pencampur rasa, mesin pemotong dan pembentuk, dan mesin pengepakan.

Karamel mengolah video pengoperasian mesin

Proses produksi suguhan karamel

Mesin pengaduk adonan

Mesin pengaduk adonan berfungsi untuk mencampurkan tepung dengan air, telur, dan mesin ini memiliki model yang berbeda-beda, dan Anda dapat memilihnya sesuai dengan kebutuhan Anda. Waktu pencampuran adonannya singkat, sekitar 3-10 menit.

| Model | Berat adonan(kg) | Waktu pencampuran adonan(menit) | Tegangan (v) | Daya (kw) | Mesin (kg) | Dimensi (mm) |

| 12.5 | 12.5 | 3-10 | 220/380 | 1.5 | 100 | 650*400*730 |

| 25 | 25 | 3-10 | 220/380 | 1.5 | 128 | 685*480*910 |

| 37.5 | 37.5 | 3-10 | 220/380 | 2.2 | 175 | 840*480*910 |

| 50 | 50 | 3-10 | 220 | 2.2 | 230 | 1070*570*1050 |

| 380 | 2.575 | 275 | ||||

| 75 | 75 | 3-10 | 380 | 3.75 | 475 | 1410*680*1250 |

| 100 | 100 | 3-10 | 380 | 3.75 | 490 | 1520*680*1250 |

| 150 | 150 | 3-10 | 380 | 6.25 | 700 | 1710*730*1400 |

Berat: 640kg

Mesin pengepres adonan berfungsi untuk menekan adonan menjadi bentuk pipih kemudian dipotong menjadi balok-balok kecil.

Mesin penggorengan minyak

Setelah dipotong, balok adonan kecil perlu digoreng agar bisa dimakan.

Panci masak gula

Panci masak gula adalah dengan melelehkan gula pasir menjadi bentuk pasta, lalu mencampurkan bahan-bahan seperti kacang-kacangan, wijen, gula pasir dengan adonan balok kecil menjadi satu.

Blender rasa

Jika Anda ingin suguhan karamel terasa lebih enak, Anda bisa menggunakan blender perasa untuk menyemprotkan sedikit bumbu ke permukaannya. Bumbunya bisa dibuat sesuai kebutuhan.

Mesin pembentuk dan pemotong

Mesin pembentuk dan pemotong mempunyai dua rol pengepres dan tiga kipas pendingin, yang pertama untuk menekan bahan mentah menjadi bentuk datar dan yang kedua untuk mendinginkan karamel. Karamel terakhir bentuknya seragam dan ukurannya sama.

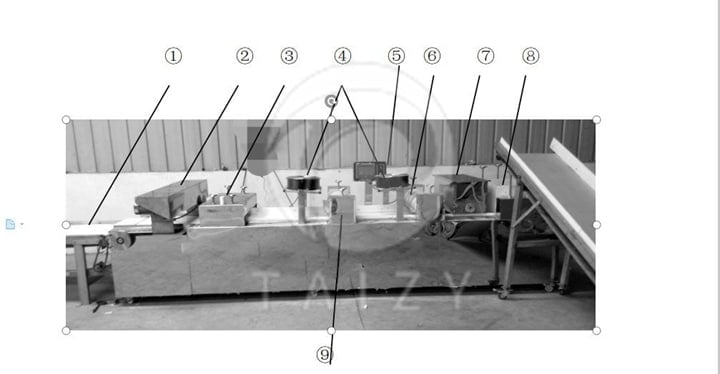

Struktur mesin pemotong dan pembentuk

1. Conveyor belt ke mesin pengemas

2. Pisau potong melintang

3. Pisau penggorok, roller penekan

4. Kipas pendingin

5. Panel kontrol utama

6. Rol penekan primer

7. Mesin penyebar bahan

8. Memberi makan hopper

9. Rol penekan sekunder

- Tampilan kecepatan mainframe

- Jumlah produksi

- produksi yang jelas

- Tampilan waktu dan tanggal

- Pengaturan parameter mainframe

- Tampilan frekuensi sabuk konveyor (0-50)

- Tombol start mainframe

- Tombol tutup mainframe

- Tampilan dinamis

- Panjang potongan kiri (0-999)

- Panjang potongan kanan (0-999)

- Tombol penghenti kipas pendingin

Mesin pengemas suguhan karamel

Mesin pengepakan adalah langkah terakhir untuk setiap jalur pengepresan makanan, dan mesin ini dapat mengemas camilan karamel ke dalam kantong kecil.

Bagaimana cara mendapatkan suguhan karamel?

1. Tempatkan nasi, gandum, kacang tanah, kacang-kacangan, dan bahan lainnya yang sudah dihaluskan dan diaduk ke dalam hopper pengumpan mesin utama melalui mesin pengumpan.

2. Kedua rol pengepres meratakan bahan mentah secara otomatis.

3. Kemudian diangkut melalui ban berjalan ke bagian pemotongan otomatis agar pemotongan silang dan pemotongan sesuai dengan persyaratan yang ditetapkan.

4. Dalam proses ini, kipas pendingin mendinginkannya, dan kemudian bahan yang dipotong dikirim ke mesin pengemas melalui ban berjalan untuk pengemasan otomatis.

Parameter teknis lini produksi suguhan karamel

| Model | TZ-SCX01 |

| Kekuatan | 380V/50HZ 3kw |

| Dimensi | 6000*1300*1200mm |

| Berat | 1050kg |

| Kapasitas | 150-300kg/jam |

| Bobot keluaran | 5g-300g |

Keuntungan dari mesin pengolah shaqima

- Sirkuit kontrol utama mengadopsi komputer mikro chip tunggal yang diimpor, antarmuka manusia-mesin, dan kontrol konversi frekuensi. Lebih mudah dan cepat untuk mengatur parameter.

- Pengoperasiannya terpusat dan intuitif, sepenuhnya mewujudkan kontrol otomatis yang manusiawi.

- Mata elektronik sensitivitas tinggi dapat melacak secara otomatis dan informasi umpan baliknya akurat, sehingga kesalahannya kecil.

- Pengoperasian yang stabil, pembentukan otomatis, pengangkutan material otomatis, dan pemotongan.

- Pengoperasian sederhana dan intensitas tenaga kerja rendah.

- Produksi dan output berkelanjutan sangat tinggi.

- Sistem transmisi mekanis kompak dan tata letaknya masuk akal.

- Sirkuitnya jelas, dan mudah dipahami serta dioperasikan.

| Kerusakan | Alasan | Larutan |

| Panel kontrol tidak menyala setelah dihidupkan. | Listrik tidak tersambung. | Periksa dan kumpulkan kekuatannya. |

| Camilan karamel tidak bisa dipotong seluruhnya. | Kesenjangan antara bilah dan ban berjalan terlalu besar. | Sesuaikan ketinggian bilah.

|

| Ketebalan suguhan karamel akhir tidak merata. | Kesenjangan roller penekan tidak proporsional | sesuaikan kesenjangannya secara proporsional |

Bagaimana cara memasang lini produksi suguhan karamel?

A. kondisi instalasi

1. Lini produksi suguhan karamel harus dipasang di dalam ruangan untuk menghindari sinar matahari langsung.

2. Tanah harus diaspal dengan lantai semen, dan harus ada sumber air pembilas dan saluran pembuangan air.

3. Mesin pengolah shaqima berventilasi baik, dilengkapi dengan kompresor udara, dan tekanan berkisar antara 0,2Mpa—0,8Mpa.

4.mesin pemroses shaqima seharusnya memiliki fasilitas penerangan yang diperlukan dan sumber daya listrik 380V.

B. Tindakan pencegahan pemasangan

1. Lokasi pemasangan umumnya dipilih dari tempat dekat sumber air keran.

2. Saat memasang, harap perhatikan untuk menyisakan ruang tertentu untuk memudahkan perawatan.

3. Untuk part yang sudah dipasang di pabrik, periksa kembali setelah dibongkar dan kencangkan apakah ada bagian yang kendor.