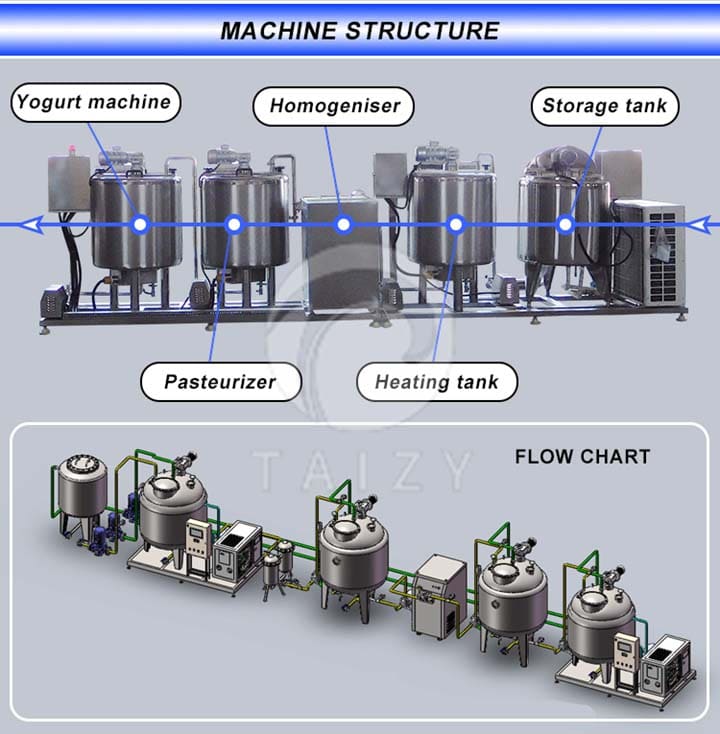

The yogurt production line is to get yogurt that is popular drinking in our daily life. The basic yogurt production process is like this: raw milk storage→ filtration→preheating→homogenization→sterilization→fermentation →filling. Therefore, The yogurt process equipment is: raw milk refrigeration tank (storage) → single filter → milk pump → preheating tank → milk pump → homogenizer → sterilizer →milk pump → fermenter →milk pump → filling machine. The whole yogurt production line is automatic, and you can get yogurt of high quality.

How does the yogurt processing line work?

Fresh milk storage

it needs cold storage at low temperature, and the temperature is 3-6 °C, which has been set at the factory. After connecting the power supply, turn on the electric control box, stir switch and compressor1.

Refrigeration tank

Open the milk pump of preheating tank electric control box, and fresh milk flows out through the refrigerating tank milk outlet (the milk outlet valve: the level shows off, and the vertical downward means on). The fresh milk passes through a single filter, filtering the impurities of the fresh milk, and entering the preheating tank through the milk pump later.

Preheating tank

Warmed up fresh milk. Turn off the milk pump after the cold milk is filtered into the preheating tank. Before preheating, you shall firstly ensure the water level of the preheating tank lining reaches the visible position of the water mirror. Then turn on the electric control box (set the water temperature 60 ° C, milk temperature 45 ° C) and the heating switch, and stir. After the milk temperature reaches 45 degrees, the alarm will ring.

Homogenizer

After preheating, open the preheating tank outlet valve. Turn on the electric control box, the power switch, and the homogenizer switch that controls the milk pump. The preheated fresh milk enters the homogenizer which comes with the pressure of the milk outlet. The homogenized fresh milk will automatically enter the sterilization tank finally.

Note: Before the homogenizer works, adjust the working pressure. First, adjust the handle 1, the pressure gauge should be 8mpa. Second, adjust the handle 2, the pressure gauge should be 17mpa.

Note: After the homogenization is completed, the pressure is released. Adjust handle 2 to release the pressure, and adjust handle 1 to rotate until the pressure is restored to the original position.

Pasteurization tank

Fresh milk sterilization.

(1). Before the operation, you shall ensure that the water level of the sterilizer is reached at the water level mirror. In addition, the operator needs to set the sterilization temperature to 85 °C, and turn on the sterilization heating and stirring switch. When the milk temperature reaches 85 °C, the alarm will ring.

(2). Sterilization tank pre-cooling. When pre-cooling, the bottom inlet faucet on the side of the sterilization tank should be opened.

(3). The cold water enters the sterilization tank lining through the inlet and is discharged from the upper water outlet. Coldwater flows through the lining, which will decrease the milk temperature.

(4). When the milk temperature drops to about 50 ℃, the pre-cooling is finished. At this time, turn on the sterilization milk pump, and the milk that has been sterilized enters the fermenter.

Fermenter

Fresh milk fermentation. The water level of the fermenter lining should reach the water level mirror before working. The fermenter temperature is set at 43℃, and the fermentation time is 8 hours. Turn on the fermentation heating and stirring switch, the operator can add related strain to ferment when the milk temperature reaches 43℃.

Yogurt filling machine

(1). Open the air compressor switch to ensure the pressure, and turn on the milk pump of the fermenter. When the fresh milk reaches a certain position of the bucket, first turn off the milk pump and then turn on the filling machine.

(2). The temperature of the control table on the filling machine firstly is 150 °C, and it should be 200 °C when reaching the preset temperature.

(3). After the disc rotates, the operator should start the touch screen from left to right in sequence. Otherwise, the program will be disordered and cannot work normally.

Note: Turn on the fermentation milk pump again when the filling machine works normally. The milk flow rate is controlled by the valve, which can keep the position of the yogurt in the barrel stable.

How to clean yogurt processing machine?

Cleaning method 1: clean each tank separately.

Cleaning method 2:

1.Add hot water/acid water/alkaline water to the refrigerating tank first, turn on the stirring and washing switch, and then turn on the milk pump 1.

2. Turn on the homogenizer switch (adjust the handle 1, and homogenizer pressure is 8mpa)

3. The hot water enters the sterilization tank for cleaning.

4. Turn on the sterilizing tank milk pump 3, and the hot water enters the fermenter.

5. Finally, the hot water is discharged from the sludge discharge port of the fermenter.

Advantage of the yogurt production line

1. Yogurt processing machine can work automatically, and different parts can connect by a milk pump.

2. The screen of the filter machine is made of stainless steel, which is corrosion-resistant.

3. The milk processed by this yogurt production line is safe and bears great taste, so the buyer can win big benefits.

A successful case of the yogurt processing machine

In July, The customers from Nigeria bought a whole yogurt production line. Actually, he is a farmer and has a very big factory that is related to cows and other livestock. He has bought 5 sets of silage baler machines from us before to feed his animals. Now, he needs such a yogurt processing machine to process the milk extracted from the dairy cow. The following pictures are the packing details.

FAQ of yogurt production line

1. What is the difference between producing liquid yogurt and solid yogurt?

Liquid yogurt needs to be equipped with related machines.

2. What is the temperature range of the refrigerating tank?

4-45 degrees centigrade.

3. What is the ratio of materials that can be added during the yogurt making process?

The ratio of milk to white sugar is: 1 liter of milk plus 6-8% of sugar, 1 g of strain

4. Which machines are needed to make yogurt?

Milking machine – preheating – sterilization barrel – homogenizer – yogurt machine – filling machine