Mstari wa uzalishaji wa saladi ya mboga moja kwa moja umeundwa kwa ajili ya usindikaji wa kina wa aina mbalimbali za matunda na mboga. Kazi kuu za laini hii safi ya usindikaji mboga ni pamoja na kukata kiotomatiki, kuosha, kukausha hewa na kufunga. Hivi sasa, mmea huu wa kusindika mboga za saladi za kibiashara hutumiwa kwa kawaida kusindika alfa alfa, chipukizi za maharagwe, lettuce, celery, karoti, viazi, kabichi, kale, vitunguu, shallots, leek, chicory, nk. Kiwanda chetu cha Taizy hutoa ufumbuzi wa turnkey kwa mboga na mboga. kukata matunda, kuosha na kufunga. Uwezo wa msingi wa usindikaji wa mstari huu wa uzalishaji wa saladi ya mboga ni kuhusu 500kg/h-3000kg/h.

Kwa nini uanzishe biashara ya kutengeneza saladi za mboga?

Kadiri viwango vyetu vya maisha vinavyoboreka, mahitaji ya watu ya ubora wa maisha yanazidi kuongezeka, kwa hivyo mahitaji yao ya matumizi yanaboreshwa zaidi na zaidi. Hapo awali, tulinunua mboga katika maduka makubwa ya matunda na mboga, na tulihitaji kuwapeleka nyumbani kwa ajili ya uteuzi, kusafisha, kukata, nk. kupikwa moja kwa moja.

Hakuna washindani wengi wanaohusika katika sekta ya mboga safi, na hakuna shinikizo kubwa la ushindani sokoni. Hata hivyo, pamoja na ongezeko zaidi la mahitaji katika soko la mboga za saladi, itaendelea kupokea tahadhari ya mtaji katika siku zijazo. Na, sasa teknolojia safi ya usindikaji wa mboga na vifaa pia vinabuniwa kila wakati, na kuweka msingi wa kiufundi kwa maendeleo ya tasnia.

Maombi ya mstari wa usindikaji wa mboga ya saladi

- Kiwanda cha kusindika matunda na mboga kabla ya kusindika

Kulingana na kanuni yake ya uhifadhi na teknolojia ya usindikaji, aina za bidhaa za matunda na mboga za usindikaji wa awali zinaweza kugawanywa katika bidhaa za makopo, bidhaa kavu, bidhaa za sukari, bidhaa za juisi, bidhaa za pickled, bidhaa za pombe, bidhaa za waliohifadhiwa, na bidhaa zilizokatwa safi, na makundi mengine nane.

- Kituo cha uhamisho wa mboga

Vituo vya uhamisho wa mboga hutatua tatizo la magari ya nje dhidi ya magonjwa ya milipuko na wakati huo huo, ili kuongeza kasi ya ufanisi wa usafiri na utoaji wa mboga.

- Maji ya matunda na jam kina usindikaji kabla ya usindikaji

Usindikaji wa blueberries, blackberries, raspberries, jordgubbar, na matunda mengine, ikiwa ni pamoja na juisi ya wazi, maji ya mawingu, makini ya juisi na jam, na bidhaa nyingine.

- Kukausha matunda na mboga kufungia-kukausha kabla ya usindikaji

Matunda na mboga kwa njia ya kukausha, kugandisha-kukausha ili kuhifadhi rangi na ladha ya viungo, na nguvu ya kurejesha maji mwilini, inaweza kudhibiti usambazaji na mahitaji, na kuboresha thamani ya ziada ya bidhaa.

- Ugavi wa maduka makubwa na mgahawa

Baada ya kuosha, kukata, kukausha, na kufunga matunda na mboga, zinaweza kuuzwa moja kwa moja katika maduka makubwa. Au kununuliwa kwa wingi na migahawa kwa ajili ya usindikaji wa vyakula mbalimbali.

Kawaida, wateja wanaweza kusambaza mboga za saladi zilizosindikwa kwa maduka makubwa ya mboga, migahawa mikubwa, hoteli, maduka ya rejareja, nk.

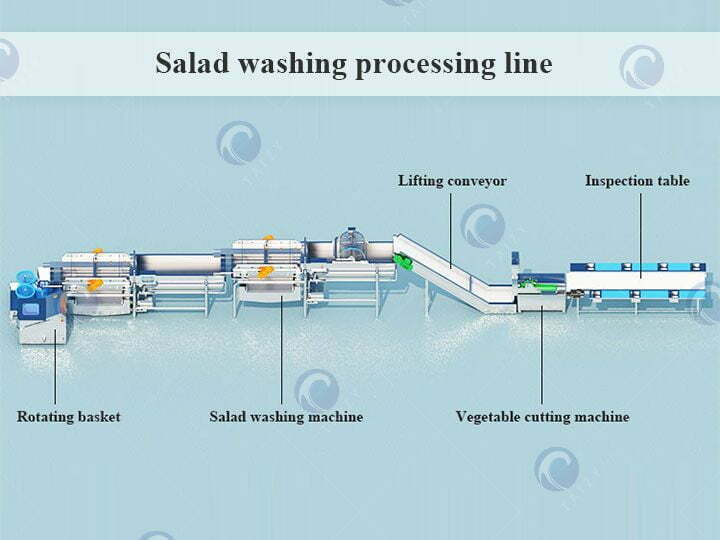

Vipengele vya mstari wa uzalishaji wa saladi ya mboga

Vifaa vya msingi vya laini hii ya usindikaji wa mboga za majani ya aina ya vortex hasa ni pamoja na meza ya kuokota, mashine ya kukata mboga otomatiki, conveyor ya pandisha, kitengo cha kusafisha vortex, mashine ya kuondoa maji, nk. Huu ni usanidi wa kawaida wa laini ya usindikaji wa matunda na mboga unaotolewa na kiwanda chetu. Bila shaka, tunaweza pia kutoa mfululizo wa mashine za kufungashia, kama vile mashine ya kufungashia saladi (begi au kisanduku), mashine ya kufungashia mboga safi iliyokatwa, au mashine ya kufungia mboga iliyofifia kulingana na mahitaji mahususi ya mteja.

Kuchukua conveyor

Jedwali la kuokota na kupeleka ni muhimu sana katika kuosha matunda na mboga na mistari ya ufungaji. Katika mstari wa kusafisha vortex ya matunda na mboga, meza ya kuokota kwa ujumla iko katika mchakato wa kwanza wa mstari wa usindikaji. Kabla ya matunda na mboga kukatwa vipande vipande, wanahitaji kupitia mchakato rahisi wa kuokota ili kuondoa uchafu kama vile matunda na mboga zilizoharibika na majani.

Mashine ya kukata mboga

Kikataji hiki cha mboga kiotomatiki kimetengenezwa kwa chuma cha pua 304 na kinaweza kutumika kwa kukata, kukata, kukata na kusaga kila aina ya mboga za mizizi na mboga za majani, nk. Kisu cha kukata cha mkataji wa mboga hii kinaweza kubadilishwa na kutumika kukata maumbo tofauti. na ukubwa wa mboga.

Hoit conveyor

Kiinua kiotomatiki cha kiwanda cha kusindika lettuki kimeundwa mahsusi kuinua mboga zilizokatwa kwenye washer ya vortex. Baffle kwenye conveyor ya kuinua imetengenezwa kwa nyenzo za PE za kiwango cha chakula, ambazo hazitachafua mboga.

Vortex kitengo cha kusafisha

Sehemu ya kitengo cha kusafisha vortex hasa inajumuisha mashine ya kuosha ya vortex na skrini ya vibrating. Tofauti na washer wa Bubble wa kawaida, washer wa vortex ina turbine yenye nguvu ambayo mara kwa mara hupiga Bubbles nyingi kwenye tanki la maji. Kwa hiyo, mboga zilizokatwa zitapigwa kwenye bwawa la tank, kufikia athari ya kusafisha kabisa. Kwa kuongeza, hakuna ukanda wa mesh katika washer wa vortex, kwa hiyo hakuna jamming ya mboga za majani.

Kwa kuongeza, kupitia skrini ya vibrating ya kuondolewa kwa maji kwenye duka, matunda na mboga zilizosafishwa zinaweza kutikisa haraka matone ya maji kwenye uso. Hii inaweza kuboresha ufanisi wa kuondoa maji katika usindikaji unaofuata.

Mashine ya kumwagilia

Mashine hii ya usindikaji wa aina ya kundi hutumiwa hasa kwa umwagiliaji wa haraka wa vipande vya matunda na mboga vilivyosafishwa. Ngoma yake ya kuondosha maji iliyojengewa ndani imetengenezwa kwa nyenzo za hali ya juu za chakula za PE, ambazo hazitachafua mboga na ni sugu kwa kuvaa na kupasuka. Kwa kawaida tunauza mashine hizi za kuondoa maji na ngoma 2-3 za ziada za kuondoa maji ambazo zinaweza kubadilishwa.

Jinsi ya kufunga mboga safi ya saladi?

Kuna njia mbalimbali za kufunga saladi ya mboga, zile za kawaida zaidi ni pamoja na mifuko, ndondi, ufungaji wa utupu na ufunikaji wa joto. Kiwanda chetu kinaweza kupendekeza mashine sahihi ya ufungaji, na vipimo vya ufungaji, na hata kubinafsisha mwonekano wa kifungashio cha mboga kwa wateja wetu kulingana na mahitaji yao ya ufungaji wa mboga za saladi, nk.

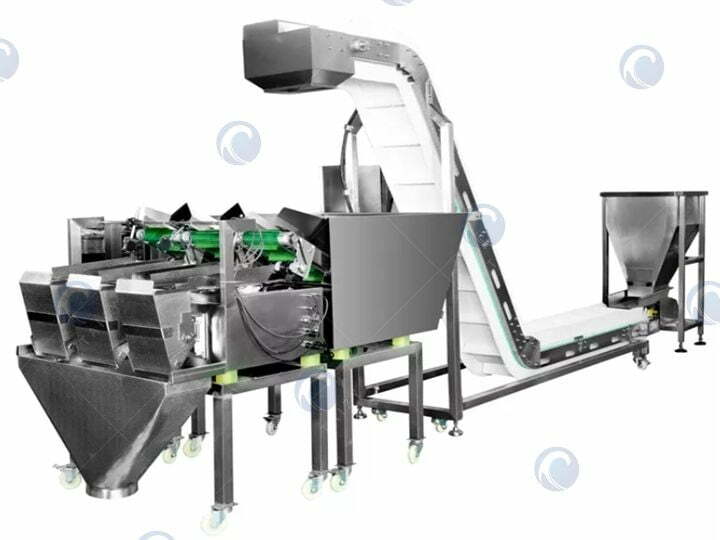

Mashine ya ufungaji ya mto inaweza kupakia saladi ya mboga katika saizi tofauti za mifuko na masanduku. Saizi ya kifurushi na uzito vinaweza kubinafsishwa kulingana na mahitaji ya mtumiaji.

Mashine hii inayoendelea ya uzani wa kiotomatiki inaruhusu mboga zilizokatwa kugawanywa kwa uzito. Mashine hii inaweza kutumika kwa kushirikiana na mashine ya ufungaji na ni bora kwa mimea kubwa ya usindikaji wa matunda na mboga ili kuotosha uzalishaji wa mboga za saladi.

Video ya mmea wa kusindika saladi ya lettu

Nani atahitaji kuosha na kufunga mistari ya saladi ya mboga?

Tumehesabu data ya wateja wetu katika miaka mitano iliyopita na kugundua kuwa wateja walionunua laini zetu za uzalishaji wa saladi za mboga wanatoka zaidi ya nchi na mikoa 40. Miongoni mwao, wateja walioagiza vifaa vya kuosha mboga ni kutoka Misri, Kanada, Uturuki, Uingereza, Marekani, Italia, Ufaransa, Kanada, Qatar, Uturuki, Indonesia, Saudi Arabia, Australia n.k. Aidha, wengi wa hawa wateja wanajishughulisha na kazi zinazohusiana na usindikaji wa mboga, kama vile wasindikaji wa mboga waliohifadhiwa; viwanda vya kusindika jikoni kuu, maduka makubwa ya minyororo, viwanda vya kusindika mboga, wachuuzi wa saladi, wauzaji wa mboga za shambani, n.k.

Laini kamili ya kuosha na kufunga mimea ya Alfalfa iliyosafirishwa hadi Australia

Hivi majuzi, kiwanda chetu kilisafirisha laini ya kusafisha chipukizi ya alfalfa ya 1t/h hadi Australia. Mteja alinunua laini kamili ili kusafisha chipukizi za alfa alfa na kufungasha chipukizi zilizosafishwa ili kuziuza kwenye maduka makubwa ya mboga. Kwa kweli, mmea pia unaweza kutumika kusindika aina zote za chipukizi za soya, michipukizi ya maharagwe ya mung, lettuce, nk kwa njia sawa.

Vigezo vya mashine ya laini ya kuosha Alfalfa sprouts ya Australia

| Kipengee | Vipimo |

| Mashine ya kuosha ya Vortex + mashine ya vibrate | Mfano: TZ-1000 Uwezo: 1000kg/h Vipimo: 4200 * 1120 * 1600mm Nguvu: 4.4KW Voltage: 380V, 50hz, awamu ya 3 Urefu wa kuagiza na kuuza nje: 1550mm/1200mm Uzito wa mashine: 600kg Nyenzo za mashine: 304 chuma cha pua Kumbuka: mashine ya kuosha na roller na mixer |

| Spin dryer | Mfano: TZ-200 Ukubwa: 1000 * 650 * 1000mm Voltage: 380V, 50hz, awamu ya 3 Nguvu: 1.5kw Kipenyo cha kikapu: 49cm Nyenzo za mashine: 304 chuma cha pua Kasi: 600r / min |

| Duplex 3-kichwa Saladi Weigher | Mfano: TZ-3 Kupima kichwa: Vichwa 3 Kiasi cha ndoo ya uzani: 8000ml Uzani wa safu: 50 ~ 2000g Kasi ya uzani: 5 ~ 15 mfuko / min Usahihi: ± 1 ~ 30g Voltage: 380V, 50Hz, 3Awamu Ukubwa: 1770 * 1600 * 1290mm Uzito: 400kg Kumbuka: 1. Kiini cha Upakiaji cha Usahihi wa Juu 2. Udhibiti wa Skrini ya Kugusa ya PLC 3. Nyenzo za mashine: SUS 304 Chuma cha pua 4. Urefu wa duka uliobinafsishwa 1m 5. Kwa magurudumu |

| Mashine ya kufunga mito | Mfano: TZ-250 Nguvu: 2.5kw Kasi ya Ufungashaji: 40-230pcs / min Bidhaa ni ya juu: 5-40mm Upana wa utando:≤250mm Urefu wa kufunga: 5-60mm Ukubwa: 3770 * 670 * 1450mm Uzito: 800kg Bei inajumuisha 1. Mfumo wa kusafisha nitrojeni 2. Kazi ya tarehe ya uchapishaji 3. Kwa brashi 4. Kazi ya kutolea nje 5. Servo motor ( Nyenzo ya utangulizi na kulingana na urefu tofauti ili kurekebisha kiotomatiki) |

| Maoni: 1. Muda wa uzalishaji: takriban siku 15-20 za kazi. 2. Udhamini: miaka 2. 3. Masharti ya malipo: amana ya 50%, salio la 50% kabla ya kutumwa kwa T/T. 4. Masharti ya Uhakikisho wa Ubora: A. Muuzaji huhakikishia mashine na vifaa vyake ni vipya, muda wa udhamini wa mashine hii ni mwaka 1 kutoka tarehe ya mashine kufika mahali pa mnunuzi. B.Wakati wa kipindi cha dhamana ya ubora, kwa matatizo yoyote yanayosababishwa na uendeshaji usio sahihi na mnunuzi, muuzaji hutoa huduma ya matengenezo ya ujuzi wa bure. Muuzaji hutoa huduma ya kiufundi ya milele na vipuri kwa bei ya gharama. |

Je, ni uundaji wa jumla wa chaîne de cette??

Nimefurahi kupokea uchunguzi wako, nitakutumia maelezo kupitia barua pepe hivi karibuni