Mashine ya soseji hutumiwa kutengeneza soseji. Mchakato wote ni moja kwa moja, kuokoa muda mwingi na nishati. Inajumuisha mashine saba kama vile grinder ya nyama, mashine ya kukata na kuchanganya nyama, mchanganyiko wa kujaza, mashine ya kujaza soseji, mashine ya kuunganisha soseji, tanuri ya sausage ya kuvuta sigara, na mashine ya kufungashia ya utupu.

150kg/h orodha ya mashine ya uzalishaji sausage na vigezo

| Mashine | Uwezo (kg / h) | Nguvu (kW) | Ukubwa (mm) | Uzito (kg) |

| Kusaga nyama | 300-500 | 4 | 950 * 550 * 1050 | 240 |

| mashine ya kukata nyama

| 150-200 | 5 | 780 * 600 * 850 | 300 |

| mashine ya kuchanganya sausage | 160 | 2.2 | 1350 * 820 * 1350 | 400 |

| mashine ya kujaza sausage

| 300 | 0.75 | 530 * 410 * 1350 | 120 |

| mashine ya kufunga sausage | 10〜Vifundo 100/dakika vinaweza kubadilishwa | Crank ya Mwongozo | 650 * 550 * 450 | 18 |

| oveni ya sausage ya kuvuta sigara

| 150 | 6 (mvuke) | 1700 * 1300 * 2400 | |

| mashine ya kufunga sausage

| Bechi 2-5/dak | 2.5 | 1680 * 780 * 1000 | 480 |

Video ya kazi ya kutengeneza soseji

Kusaga nyama

Kisaga cha nyama ni hatua ya kwanza ya mstari wa uzalishaji wa sausage. Inakata nyama ndani ya pellets za vipimo tofauti. Malighafi inaweza kuwa nyama safi au nyama iliyogandishwa chini ya -18°C. Grinder ya nyama haitaharibu tishu za nyuzi za misuli ya nyama, na ongezeko la joto la nyama ni ndogo, ambalo linafaa kwa kuhifadhi. Inaweza kudumisha lishe na ladha safi ya nyama na kupunguza upotezaji wa protini.

Kipenyo cha sahani ya orifice ya grinder ya nyama inaweza kubinafsishwa kulingana na mahitaji ya bidhaa ya kumaliza ya mteja. Tunaweza kubinafsisha sahani za orifice na kipenyo cha 4-15mm.

Mchanganyiko wa kukata nyama

Mchanganyiko wa kukata nyama unaweza kukata nyama katika hali ya maridadi na kuchanganya viungo vingine sawasawa. Operesheni kama hiyo inaweza kuzuia myoglobin ya misuli, mafuta na virutubishi vingine kutoka kwa oksidi na kuharibiwa, na hivyo kubakiza rangi asili, harufu, ladha, na yaliyomo anuwai ya virutubishi. Mashine hii inaweza kuboresha laini ya nyama na kuongeza elasticity kwa kukata na kuchanganya.

Mashine ya kuchanganya sausage

Mashine ya kuchanganya utupu hutumika zaidi kwa soseji na pia ndicho kifaa kinachopendekezwa kwa ajili ya kutengeneza vyakula vilivyogandishwa haraka. Kupitia shinikizo hasi ya utupu, kujaza chakula, kujaza nyama hupanuliwa kikamilifu kwa unyumbufu mzuri na rangi angavu. Zaidi ya hayo, hakuna mapovu ndani ya nyama. Mchanganyiko wa kipekee unaweza kusafisha nyama ya kusaga. Baada ya usindikaji wa nyama, protini ya wanyama kati ya nyuzi za nyama inaweza kupunguzwa kwa uhuru, ambayo inaweza kuhakikisha kuwa nyama huchochewa sawasawa katika hali ya fluffy. Mchuzi ulioongezwa unaweza kufyonzwa kikamilifu, na kufanya stuffing kuwa laini na zabuni. Mashine hiyo inafaa kwa mikahawa, hoteli, viwanda vya kusindika vyakula, viwanda vya kutengeneza dawa, mimea kemikali n.k. Soseji iliyochakatwa nayo hutengwa na oksijeni, na hivyo kupunguza ukuaji wa bakteria na kuboresha kutetemeka kwa nyama.

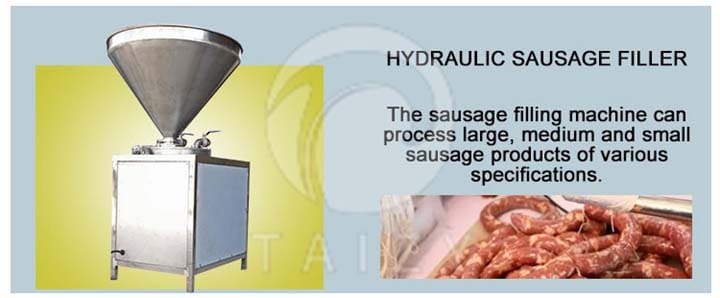

Mashine ya kujaza sausage

Mashine ya kujaza sausage ni vifaa vya lazima katika mtengenezaji wa sausage. Inaweza kujaza soseji kubwa, za kati na ndogo zenye vipimo mbalimbali, ikitumika kwa wingi kujaza maganda ya wanyama, maganda ya protini na maganda ya plastiki. Mashine ya kujaza sausage ni rahisi kufanya kazi, na sehemu zote zimetengenezwa kwa chuma cha pua na sifa salama na za usafi. Hopper yenye uwezo mkubwa hufanya iwe ya ufanisi na ya haraka. Pia ina vifaa vya kubadili uhamisho, udhibiti wa pedal mbili.

Mashine ya kufunga sausage

Mashine ya kufunga soseji ni kufunga waya kati ya sausage na kuzitenganisha kikamilifu. Inakubali muundo wa kishindo cha mkono, ikifunga waya kiotomatiki kwa ufanisi wa juu na kasi ya haraka.

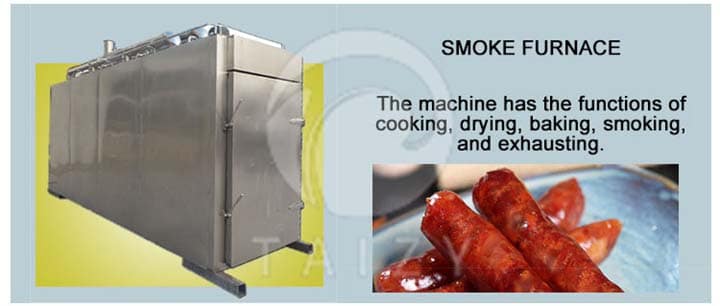

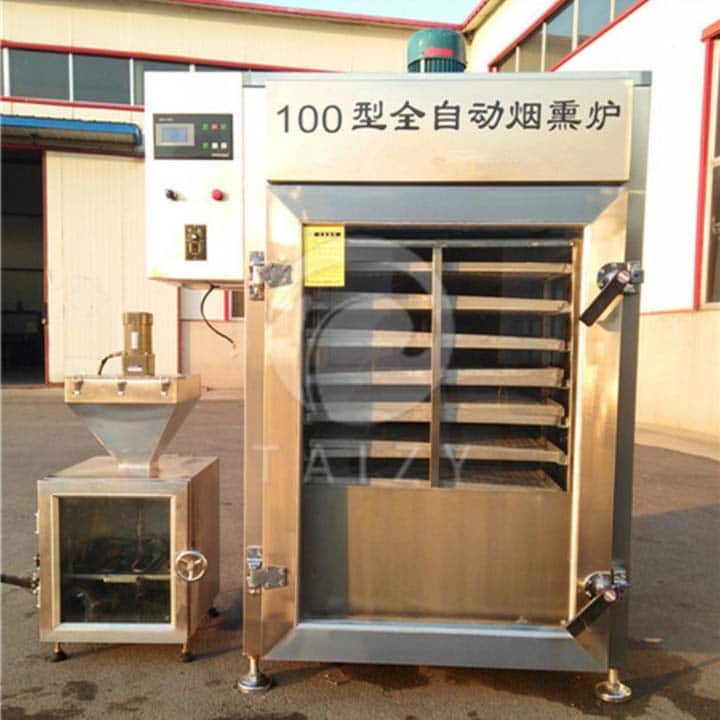

Tanuri ya sausage ya kuvuta sigara

Wakati wa mtengenezaji wa sausage, tanuri ya sausage ya kuvuta ni kuvuta sausage, na ni sehemu muhimu ya mstari wa uzalishaji wa sausage. Ina kazi za kupika, kukausha, kuoka, kuvuta sigara, kutolea nje, kusafisha, nk. Sausage ya kuvuta sigara ina ladha bora.

Mashine ya kufunga sausage

Mashine ya ufungashaji wa ombwe ni utupu na kisha kuifunga bidhaa ili vitu vilivyofungwa viweze kutenganisha oksijeni, kuzuia unyevu, kuzuia ukungu, kuzuia kutu, kuzuia kutu, kuzuia wadudu, kuzuia uchafuzi wa mazingira, nk. inaweza kuongeza muda wa maisha na uhifadhi ili kuhifadhi na kusafirisha. Inafaa kwa kufunga chakula kilichopikwa, dawa, kemikali, vyombo vya usahihi, nguo, bidhaa za vifaa, vipengele vya elektroniki, mbalimbali imara, poda, kioevu, nk.

Faida ya mtengenezaji wa sausage

- Soseji iliyochakatwa huzaa ladha ya bidhaa, na ndiyo inayouzwa zaidi kwenye soko la chakula.

- Sausage ya mwisho ni intact na ukubwa sawa.

- Mstari mzima wa uzalishaji wa sausage unajivunia utendaji thabiti na uwezo wa juu.

- Kila mashine ina mifano tofauti, na unaweza kuchagua inayofaa kulingana na hitaji lako.

Uzalishaji wa sausage line kuuza nje ya Australia

Mteja kutoka Australia ambaye anajishughulisha na utengenezaji wa patties za hamburger anataka kupanua wigo wa uzalishaji na biashara. Anapanga kufungua laini ya uzalishaji wa soseji. Na alituuliza kwa undani juu ya mashine yetu. Tulimpa maelezo ya kina kuhusu kila mashine na video ya uendeshaji wa mashine. Mteja na mshirika wake wa biashara walichunguza mashine yetu kwa undani na kutuuliza kuhusu maelezo ya kusafisha na voltage ya mashine.

Mashine zote kwenye mashine ya kuchakata soseji ni chuma cha pua na zinaweza kuoshwa moja kwa moja na maji. Na tunaweza kubadilisha voltage ya kila mashine kulingana na mahitaji ya voltage ya ndani ya mteja. Mahitaji ya voltage ya mteja ni 480v 60hz, tunathibitisha na mafundi wetu, tunaweza kukidhi kuridhika nayo. Aidha, pia anahitaji mashine ya kukata nyama iliyogandishwa, mashine ya kamba, mashine ya kukoboa nyama na mashine nyinginezo. Wakati wakiijadili kwa kina mashine hiyo, mteja aliwasilisha nyaraka za ununuzi wa mashine hiyo serikalini. Baada ya kupata kibali cha ununuzi, aliweka agizo moja kwa moja kwetu.

Maswali Yanayoulizwa Mara kwa Mara ya mtengenezaji wa soseji

1. Malighafi ni nini?

Malighafi inaweza kuwa nyama safi au nyama iliyohifadhiwa.

2. Je, mtengenezaji wa soseji ana uwezo gani?

Tuna mifano tofauti kwa kila mashine, kwa hivyo anuwai ya uwezo ni kubwa.

3.Je, soseji lazima ivutwe?

Inategemea mchakato wa uzalishaji wa mteja.