This automatic chicken meat cutting machine simulates the manual dicing process and the dicing device adopts the principle of “shifting mechanism” and “automatic feeding”. It uses the main and auxiliary crankshaft linkage mechanism. It mainly includes a transmission device, and widely applies in various dicing processing of poultry, meat, spare ribs, and so on.

Mashine ya kukata nyama ya kuku inaweza kukata nyama mbalimbali katika vipande, vipande, nk. Mashine ina muundo wa kuridhisha na utendaji wa hali ya juu (400-500kg kwa saa), uendeshaji rahisi, matengenezo ya urahisi, matumizi makubwa, utendaji wa gharama nafuu, na kazi. -kuokoa. Muhimu zaidi, inaweza kutumika kwa nyanja nyingi kama vile viwanda vidogo na vya kati vya kusindika chakula, canteens, machinjio, viwanda vya kusindika nyama, maduka makubwa, mikahawa ya haraka, n.k., kuboresha sana ufanisi wa kazi. Ni kifaa bora cha usindikaji wa kuku kwa watumiaji.

Maombi ya mashine ya kukata nyama ya kuku

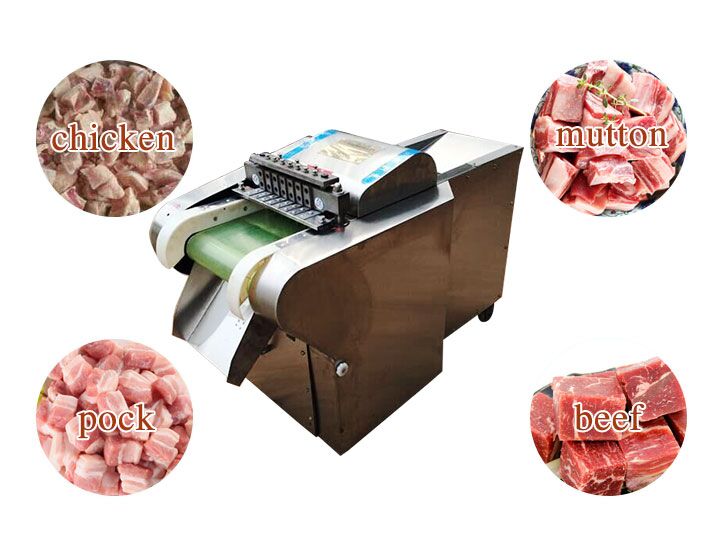

The meat cutter machine can cut fresh or frozen meat such as chicken, duck, goose, fish, pork ribs, etc. to different specifications. Most importantly, the length of the cutting block can be adjusted by the eccentric wheel, from15mm to 50 mm. With intermittent feeding, processing, and forming rules, the chicken pieces are well organized, greatly reducing the labor intensity.

Video ya mashine ya kukata nyama ya kuku kibiashara

Kigezo cha kiufundi cha mashine ya kukata nyama

| Uwezo | 400-500kg / h |

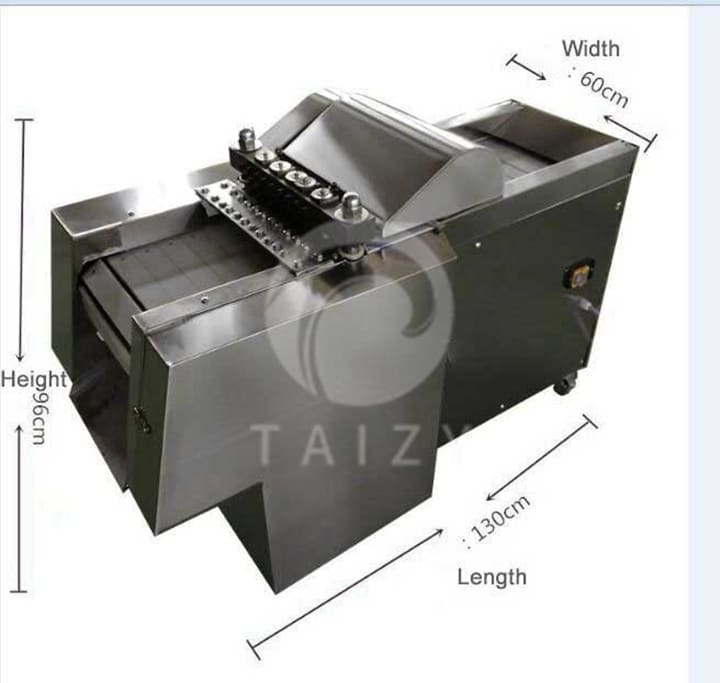

| Ukubwa | 1300x600x960mm |

| Nguvu | 220v (3. 0kw) 380v (2. 2kw) |

| Uzito wa jumla | 250kg |

| V ukanda | B1016 |

| Urefu wa nyama iliyokatwa | 15-50 mm |

| Ukanda wa conveyor | 310×1500 |

Mashine ya kukata nyama kawaida ina mfano huu, lakini ina pato la juu, 400 ~ 500kg / h. Na ukubwa wa nyama iliyokatwa na mashine hii ya kukata kuku inaweza kubinafsishwa. Kawaida tu haja ya kuchukua nafasi ya blade ili kufikia athari, urefu wa vipande vya kuku ni 15 ~ 50mm.

Muundo wa mashine ya kukata nyama ya kuku

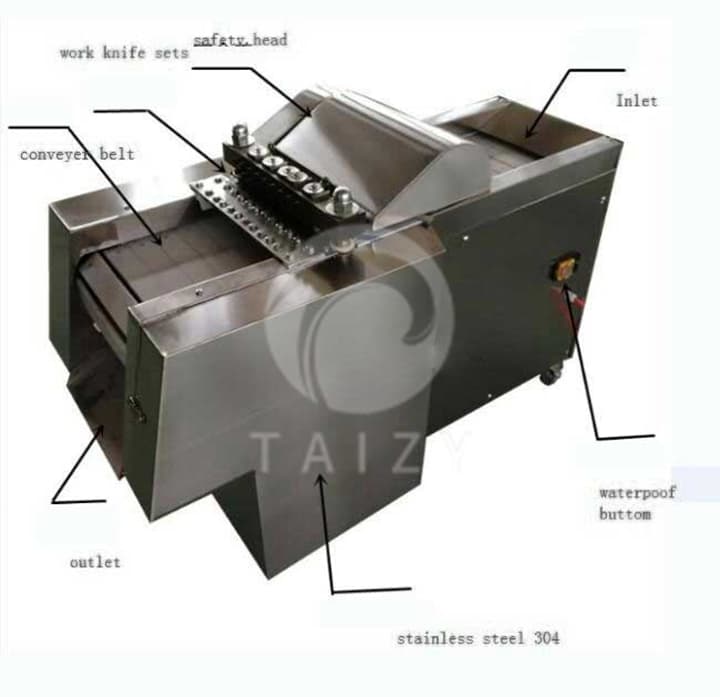

Mashine ya kukata nyama ya kibiashara inajumuisha fremu, ukanda wa kusafirisha, ubao sugu wa kukata, utaratibu wa gia na rola.

Faida za mashine ya kukata kuku

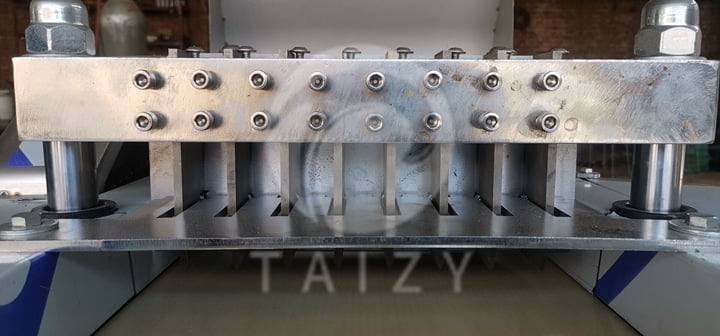

- Vile 8 vinachukua chuma cha alloy, ambacho ni mkali sana na kinaweza kukata nyama haraka.

- Kuna cheni 8 kwenye mashine ambazo zinaweza kuwezesha nyama kutotembea kiholela.

- Programu pana. Mashine za kukata nyama zinaweza kukata nyama safi au iliyogandishwa ya kuku, bata, bata, samaki, mbavu za nguruwe, na mifupa mingine.

- Sura ya nyama iliyokatwa ni sare.

- Urefu wa vile vile unaweza kubadilishwa.

- Upana wa nyama hauwezi kubadilishwa, lakini urefu unaweza kubadilishwa, yaani, 15-30mm.

- Kwa nyama iliyohifadhiwa, tunaweza pia kutumia a mkataji wa roll ya nyama waliohifadhiwa. Mashine inaweza kukata nyama iliyohifadhiwa kwa vipande nyembamba.

Jinsi ya kufunga na kupima mashine ya kukata nyama?

- Weka mashine ya kukata kuku chini ili kuhakikisha kuwa mashine inafanya kazi vizuri.

- Angalia ikiwa kuna jambo lolote la kigeni kwenye ukanda wa conveyor na usafishe ili kuepuka uharibifu wa chombo. Washa nishati ili kuangalia kama mwelekeo wa mzunguko wa gari ni sawa inavyohitajika.

- Jaribu mashine ya kukata kuku kabla ya kufanya kazi, na uangalie ikiwa vipimo na mahitaji ya nyama yanalingana. Vinginevyo, urefu wa sehemu iliyokatwa inapaswa kubadilishwa.

Kumbuka: Mafuta ya kulainisha yanapaswa kuongezwa kwenye shimo la mafuta kabla ya kuanza.

Kesi iliyofanikiwa ya mashine ya kukata nyama

Fresh or frozen meat cutting machine is a hot sale product in our factory, and we almost export it monthly. What’s more, all machines received good feedback from our customers because the machine performs well. One meat cutter machine was delivered to Lebanon this week, and the following are the packing details.

Maswali Yanayoulizwa Mara kwa Mara

- Je, urefu wa kukata unaweza kubadilishwa?

Ndiyo, inaweza kubadilishwa, na urefu wa kukata ni kati ya 15-50mm.

- Malighafi ni nini?

Mashine hukata nyama mbichi au iliyogandishwa kama vile kuku, bata, bukini, samaki, mbavu za nguruwe na mifupa mingine.

- Je, ni vipuri vilivyo hatarini?

Wao ni vile na mikanda na inapaswa kubadilishwa kwa wakati ikiwa kuna kuvunjwa.

Ongeza Maoni