A máquina de sumo de maracujá é um equipamento especial de extração de sumo para a flor da paixão (maracujá). Ao espremer o sumo da flor da paixão (maracujá), a polpa e as sementes são separadas, obtendo-se finalmente o sumo da flor da paixão (maracujá), a casca do maracujá e as sementes do maracujá, respetivamente.ªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªªª123,

As máquinas de sumo de maracujá comerciais não são apenas máquinas de sumo de maracujá, mas também descascadoras de maracujá e extratoras de sementes de maracujá.

Parâmetro técnico da máquina espremedora de maracujá

| Nome | Máquina espremedor |

| Capacidade | 0,5-1T/H |

| Poder | 2,2 kW |

| Dimensão | 1900×850×2260mm |

Princípio de funcionamento da máquina espremedora de maracujá

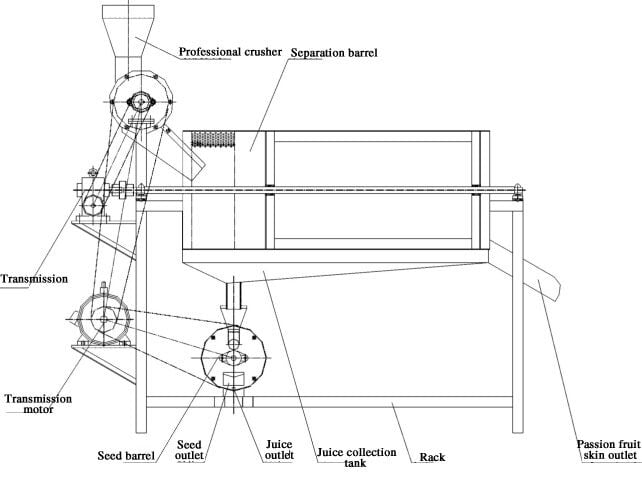

A máquina de sumo comercial é composta principalmente por um esmagador especial, um cilindro de separação, um tanque de recolha de sumo, uma saída de sementes, um rack, uma parte de transmissão, etc.

- Durante a operação, o maracujá entra no triturador a partir da moega de alimentação.

- Eles entram no barril de separação após serem esmagados.

- O suco, a polpa e a casca do maracujá rolam constantemente no barril para que possam ser totalmente separados.

- Após alguns segundos, a casca do maracujá é descarregada pelo balde de escória. O suco e a polpa caem no tanque coletor de suco e depois fluem para o cilindro de sementes que possui um raspador de sílica gel.

- O suco é raspado do pequeno orifício do tubo de semeadura e a semente é descarregada pela saída de sementes.

Vantagem do maracujá máquina de espremedor

- A máquina de suco é feita de aço inoxidável com alta resistência à corrosão e longa vida útil.

- O suco final é muito limpo e sem impurezas.

- É fácil de operar e manter.

- Pode extrair a casca e a polpa do maracujá enquanto pressiona o suco.

- Alta capacidade, ou seja, 1,5t/h, economizando muito tempo e energia.

A preocupação da máquina espremedora de maracujá

- Primeiro verifique a parte rotativa, se a rotação é flexível e se a correia e a corrente estão muito soltas.

- Habilite o sentido de rotação consistente com o sentido do sistema de direção.

- Durante o processo, verifique a taxa de quebra, a taxa de limpeza da semente e se as sementes e a polpa estão totalmente separadas. Se a taxa de limpeza for baixa, você deve ajustar a folga entre o raspador de borracha e o cilindro.

- Verifique a taxa de perda de sementes e a velocidade de descarga da polpa. Se a taxa de perda for muito alta, a altura da caçamba de escória pode ser aumentada adequadamente. Se a velocidade de descarga da carne for muito lenta, deve-se diminuir a altura da estrutura de saída da casca da máquina de suco de maracujá

- As sementes e a polpa devem ser descarregadas antes de parar para que seja fácil limpar todas as partes da máquina após o desligamento. O triturador e o tanque de coleta de suco possuem sementes acopladas, podendo-se adicionar a quantidade adequada de água para lavagem.

- O material que entra no máquina de espremedor não deve ser misturado com ferro, pedra e outros objetos duros para não danificar a máquina.

- Adicione óleo lubrificante para cada rolamento antes de usar.

- Quando a máquina é ligada, é estritamente proibido colocar a mão nela.、

Perguntas frequentes sobre a máquina de suco de maracujá

Esta máquina espremedora consegue separar totalmente as sementes, a polpa e a casca do maracujá?

Sim, sementes, polpa e casca do maracujá são descarregadas em diferentes pontos de venda.

Qual é a taxa de perda de sementes?

É menos que 2%.

E quanto à taxa de limpeza do suco final?

A taxa de limpeza é superior a 97%.

Máquina relacionada: máquina de enchimento de suco de frutas

A máquina envasadora de suco de frutas fornecida pela Taizy é uma máquina envasadora desenvolvida de acordo com as características do suco. A máquina de envase de suco também pode formar uma linha de produção de envase com máquinas como tampadoras. Todo o processo de enchimento não tem contato pessoal e é limpo e arrumado. A máquina embaladora de suco de frutas tem enchimento preciso e velocidade de enchimento rápida, o que pode ajudar grandes fábricas de produção de suco a obter enchimento em linha de montagem em grande escala.

Características da máquina de paking de suco de frutas:

- Amplamente utilizado para enchimento de semifluidos, pastas, líquidos, molhos, etc.

- O enchimento é realizado por bomba dosadora tipo parafuso, que pode ser desmontada para facilitar a limpeza e desinfecção.

- Toda a máquina adota componentes elétricos conhecidos, com desempenho estável e longa vida útil.

- De acordo com as diferentes características dos diferentes materiais, a máquina automática de envase de suco pode projetar diferentes métodos de envase de acordo com as diferentes características dos diferentes materiais.

- Adequado para encher garrafas de diferentes materiais e especificações.

- Adote tecnologia avançada para resolver com sucesso os problemas de formação instantânea de espuma, gotejamento e enchimento impreciso.