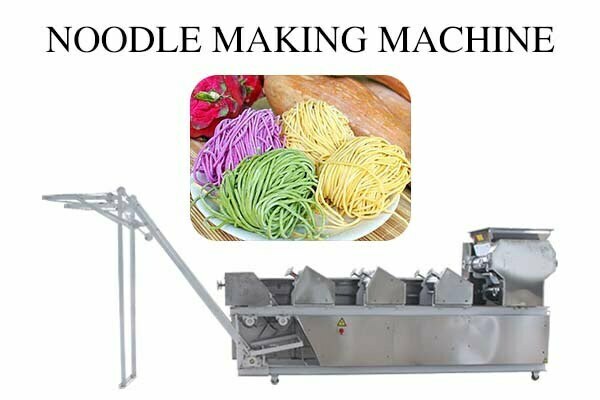

The automatic noodle making machine presses flour or dough through a dough roller to form noodles. After cutting by the blade, it forms noodles of different lengths. And by adjusting the thickness of the noodles of the rollers and the shape of the cutter, the automatic noodle machinery can produce noodles of various shapes. Such as dried noodles, hot dried noodles, etc., it can also make dumpling wrappers, wonton wrappers, and other products.

The automatic noodle maker has a high degree of automation, and it can realize various functions such as automatic noodle pressing, conveying, cutting, folding, noodles, and so on. The automatic noodle machine can process noodles of different widths and thicknesses. It fully meets the production needs of restaurants, food processing plants, canteens, and pasta processing enterprises.

Purpose of automatic noodle making machine

The automatic noodle machine can produce dry noodles and wet noodles. By adjusting the noodle roll and cutting knife, it can produce noodles with different shapes and thicknesses. Such as noodles, round noodles, long xu noodles, and other noodles.

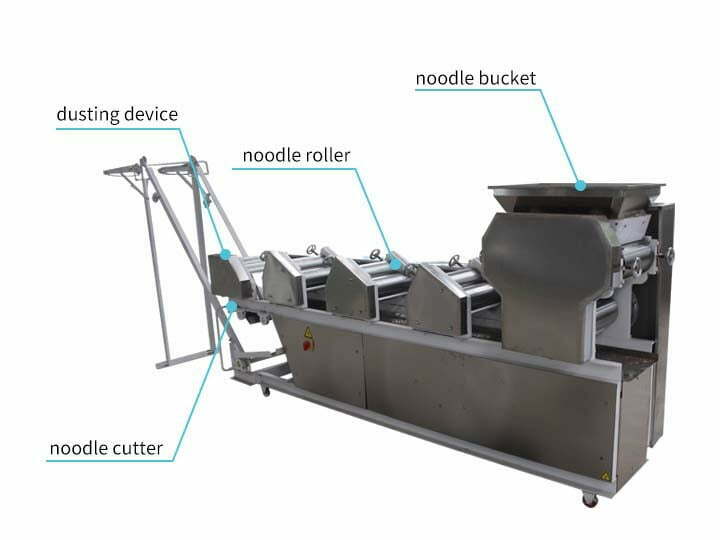

Dry noodle making machinery structure

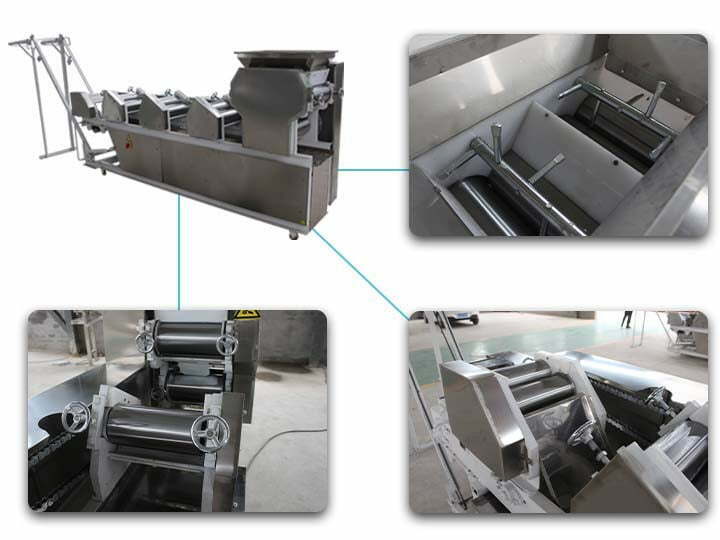

As shown in the figure, the noodle maker is mainly composed of a noodle bucket, a noodle roller, a control panel, a noodle cutter, and a dusting device.

The noodle bucket is mainly used for holding or good dough.

The pressing roller uses two pairs of rollers to squeeze the dough into a dough sheet of uniform thickness. The more the number of noodle rollers, the more times it squeezes the dough, and the noodles produced are stronger.

The intelligent digital control panel controls the operation of the entire machine.

The noodle cutter is used to cut the whole noodle block into thin and long noodles. The size and shape of the noodle cutter can be customized according to the shape and size of the noodles made by the customer.

The flour spreading device applies to spread flour on the noodles to ensure that the noodles do not stick together.

How to use a commercial noodle making machine to make noodles?

Before using an automatic noodle maker machine to make noodles, you first need to use a kneading machine to make dough. Then place the dough in the dough bucket. The dough is squeezed by multiple rollers to form a tough dough sheet. Finally, the noodles are cut into strips by the noodle cutter in front of the head of the automatic noodle machine to form noodles. And we also provide a device for hanging noodles. The automatic noodle hanging device hangs the noodles on the pole and then is dried in a dryer to form dry noodles.

The noodle machine equips with different specifications of noodle knives

The shape of noodles mainly depends on the specifications of the noodle cutter. Whether small or automatic noodle machines, we can match different specifications of noodle knives according to customer needs. Therefore, you can buy an automatic noodle forming machine and a variety of noodle cutters to make different types of noodles.

Features of automatic noodle maker machine

- A fully automatic noodle forming machine has a high degree of automation, it can automatically press noodles, dust, cutting noodles, dry noodles, and other functions.

- According to the number of noodle rollers, it has 3, 6, and 8 roller noodle presses. These noodle machines can meet the needs of large and small noodle manufacturers.

- It adopts a large pressing surface to roll the surface, which is in line with the characteristics of the noodle making process. The noodles produced are smooth and flat, with sufficient toughness, and the noodles have a smoother taste.

- The intelligent control panel makes the operation easier.

- The whole noodle making machine adopts all 304 stainless steel, and the surface of the machine body is smooth and easy to clean.

- It adopts high-strength bearings, with stable and reliable performance, and the pressure roller is easy to disassemble and clean.

- Equipped with various shapes of noodle cutters, it can make a variety of noodles.

Noodle making machine parameters

| Model | Power(kw) | Voltage(v) | Capacity(kg/h) | Size(m) | Weight(kg) |

| TZ5-250 | 3 | 380 | 140-160 | 3.2*0.68*1.37 | 510 |

| TZ6-260 | 3 | 380 | 200-260 | 3.5*0.7*1.37 | 680 |

| TZ6-300 | 4 | 380 | 250-300 | 3.5*0.75*1.37 | 700 |

| TZ7-260 | 4 | 380 | 200-260 | 3.5*0.7*1.37 | 800 |

| TZ7-300 | 4 | 380 | 250-300 | 4.2*0.7*1.37 | 870 |

| TZ7-350 | 4 | 380 | 280-320 | 4.2*0.7*1.37 | 900 |

Noodle machine makes noodles of different shapes

Automatic noodle production line

The automatic noodle production process is: noodle mixing machine → hoist → maturing machine → compound noodle pressing machine → rod feeding machine → trimming machine → hanging rod racking device → medium temperature drying → lower rack cutting machine → packaging machine

The noodle mixer is mainly used to mix various raw materials such as flour and water.

The curing machine makes the dough evenly ripened and the ripening effect is good.

The compound pressing machine adopts a fully automatic noodle forming machine to press the dough into noodles.

The automatic pole transfer device and the climbing pole loading system ensure that the noodles are smoothly transported to the dryer. It can control the neatness of the noodles.

The noodle dryer mainly ensures that the wet noodles are dried into dry noodles. The use of a dryer reduces the time to make dried noodles.

The off-rack cutting machine cuts long noodles into short noodles of uniform size

Finally, it uses a packaging machine to pack a certain amount of noodles into a packaging bag to facilitate transportation and storage.

Add Comment