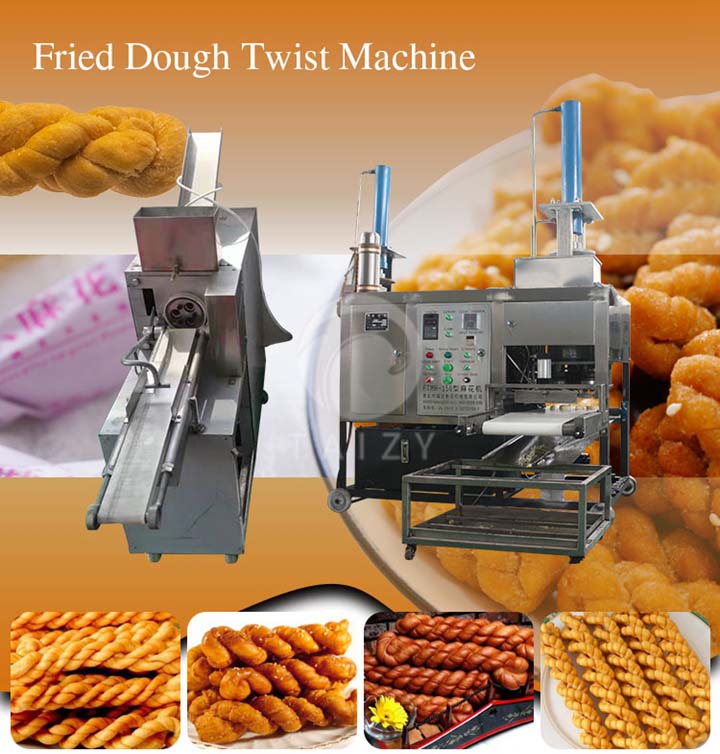

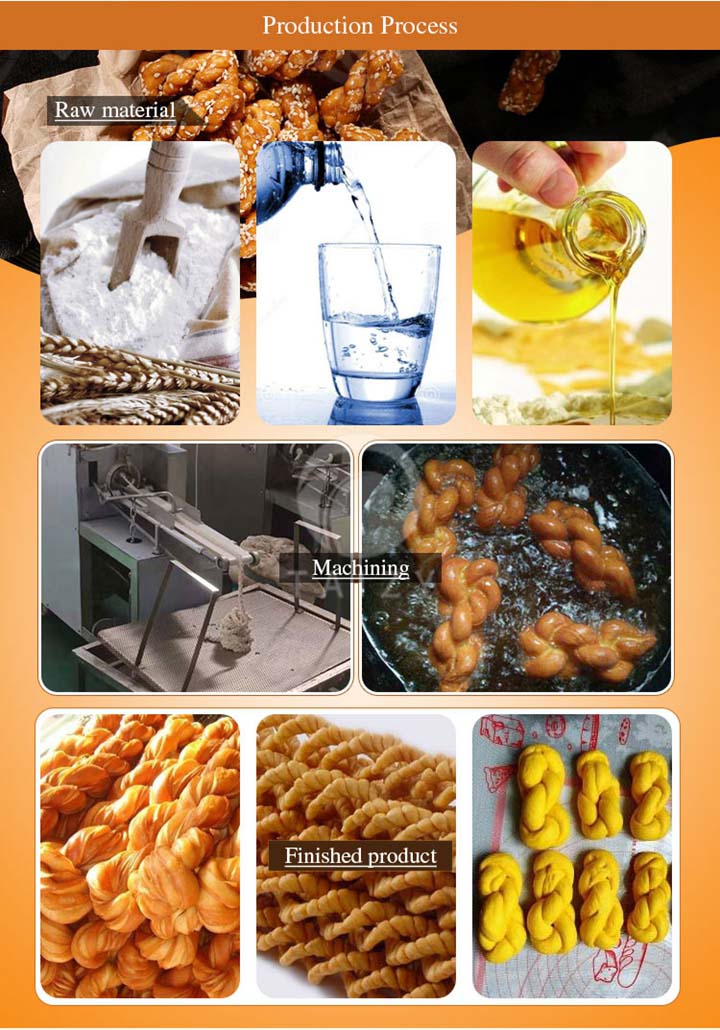

튀김 도넛 제조기는 도넛을 만드는 기계로, 단일 트위스트 기계, 유압 3개 트위스트 기계, 유압 6개 트위스트 기계로 나눌 수 있습니다. 튀김 기계와 함께 사용하면 튀김 후 도넛의 맛이 좋아지며, 제과점, 레스토랑, 스낵 식품 공장, 스낵 가게 등에 널리 적용됩니다.

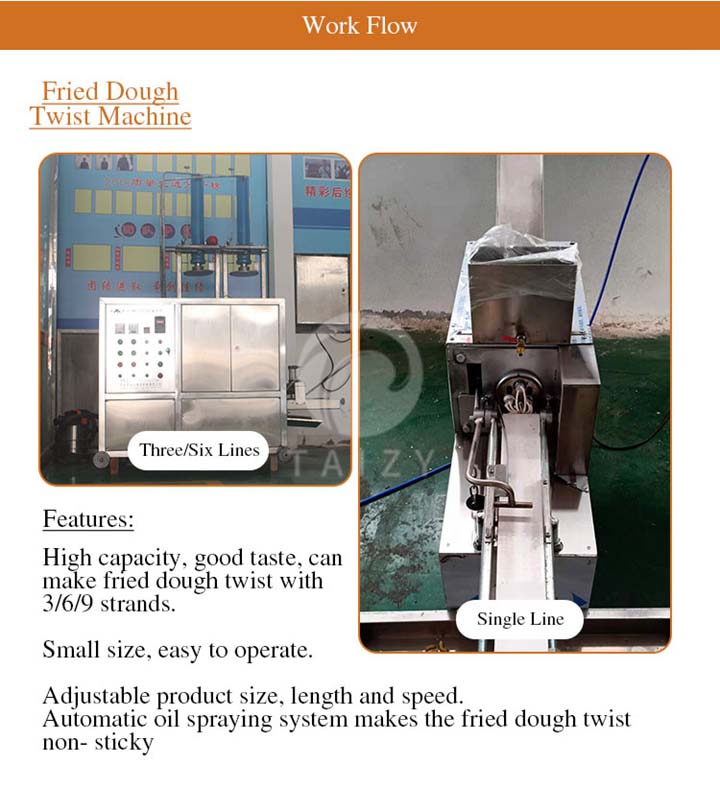

튀김 반죽 트위스트 기계의 작업 단계

- 작업 전 반죽을 준비하고, 기계에 적절한 오일을 넣어주세요.

- 반죽을 기계에 넣고 정압 푸셔의 힘으로 금형이 자동으로 회전하고 동시에 비틀림이 금형을 따라 회전합니다.

- 그런 다음 절단 장치는 트위스트를 동일한 길이로 자동으로 자릅니다.

- 뒷면에 용기를 올려 놓을 수 있습니다. 튀김 반죽 트위스트 기계 컨베이어 벨트로 이송된 후 출력물을 수집합니다.

단일 연선 기계의 기술 매개변수

| 모델 | FTMH-20 |

| 용량 | 10 키로그램/시간 |

| 전압 | 220V/380V |

| 힘 | 0.75kw |

| 빈도 | 50hz |

| 무게 | 100kg |

| 차원 | 1200*630*750mm |

유압식 세 비틀기 기계의 기술 매개변수

| 모델 | FTMH-150 |

| 용량 | 50 키로그램/시간 |

| 전압 | 380V |

| 힘 | 5kw |

| 빈도 | 50hz |

| 무게 | 400kg |

| 차원 | 1200*630*750mm |

유압식 6 연선 기계의 기술 매개변수

| 모델 | FTMH-300S |

| 용량 | 150 키로그램/시간 |

| 전압 | 380V |

| 힘 | 6kw |

| 빈도 | 50hz |

| 무게 | 500kg |

| 차원 | 1500*1300*1800mm |

튀김 반죽 트위스트 기계의 장점

1. 신축성과 길이가 조절 가능합니다.

- 성형품에 따라 두께 조절이 가능합니다.

- 튀긴 반죽의 꼬임이 풀리지 않습니다.

- 반죽 실린더에는 가열 기능이 있습니다.

- 기계의 속도는 조정 가능합니다.

- 튀김 반죽 트위스트 기계는 자동으로 식용유를 뿌릴 수 있습니다.

- 긴 수명을 가진 스테인레스 스틸로 만들어졌습니다.

- 튀긴 반죽의 맛이 맛있기 때문에 이 기계는 큰 상업적 이점을 가지고 있습니다.

- 우리는 단일, 3, 6개의 반죽 트위스트 기계를 보유하고 있으며 필요에 따라 하나를 선택할 수 있습니다.

- 그만큼 트위스트 기계 다양한 색상과 맛으로 반죽을 비틀 수 있습니다.

- 자동 변속기 및 절단은 시간과 에너지를 크게 절약할 수 있습니다.

- 손으로 비틀는 것보다 기계로 비틀어 가공한 반죽이 더 맛있습니다.

튀김 반죽 트위스트 기계의 성공 사례

7월 말, 말레이시아의 한 고객이 저희에게 문의를 보냈고, 그는 트위스트 기계 세 대를 구매하고 싶어했습니다. 그는 식품 가공 공장을 운영하며 도넛을 도매로 판매합니다. 그의 요구를 파악한 후, 저희는 그에게 튀김 도넛 제조기 한 대와 튀김 기계 한 대를 구매하도록 제안했습니다. 그는 8월 초에 계약금을 지불했습니다. 현재 저희는 기계를 잘 포장하여 그에게 배송했습니다. 저희는 그와 장기적인 파트너십을 구축할 수 있기를 바랍니다.

튀긴 반죽 트위스트 기계를 여는 단계

- 멈추다

- 시작

- 인버터(①작동 ②상단 ③회전버튼 조정

- 유압(유압 펌프 켜기)

- 위/아래(유압 실린더 상승 및 하강)

- 컨베이어(컨베이어 스위치를 켭니다)

- 컨베이어 속도(컨베이어 속도 조정)

- 오일탱크의 노즐스위치를 열고 반죽에 트위스트를 뿌려주세요.

- 커터 (공기 파이프를 연결하여 커터가 작동하도록 함)

- 길이조절 (반죽의 꼬임길이 조절)

11.실린더(반죽 실린더 스위치, 일반적으로 사용되지 않음)

12.실린더 온도

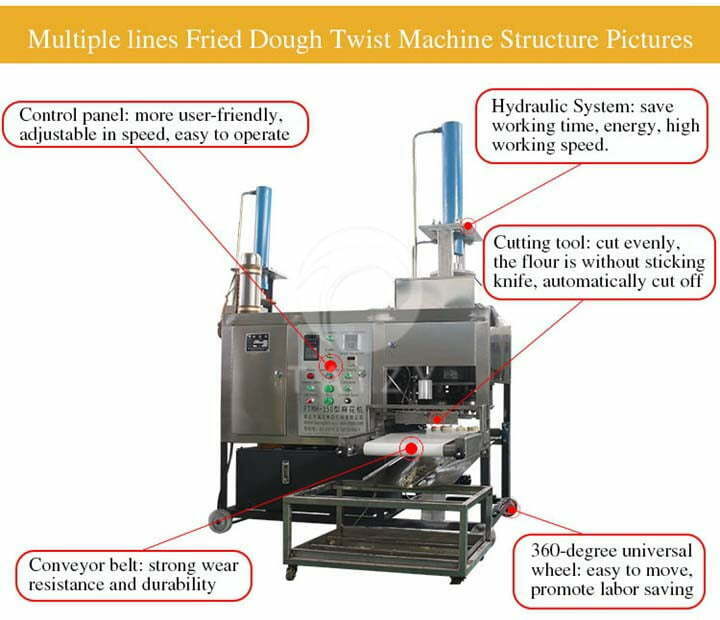

튀김 반죽 트위스트 기계의 각 부분의 기능

- 인버터: 반죽 비틀림의 견고함과 3링 기어의 속도를 제어합니다.

- 반죽통 스위치 : 날씨가 추울 때에는 미리 반죽통을 열어서 가열해 주셔야 온도가 반죽과 동일하게 유지됩니다. 추운 날씨로 인해 뒤틀림이 생길 수 있기 때문입니다.

- 반죽 꼬임 길이: 꼬임 길이를 조절하세요.

- 유압 펌프: 반죽을 금형 헤드에 짜냅니다.

- 컨베이어 속도: 인버터와 일치하도록 반죽 비틀림 배출 속도를 조정합니다.

- 커터: 반죽 트위스트를 잘라냅니다.

- 노즐: 반죽 트위스트를 스프레이

튀김 반죽 트위스트 기계의 선점

- 유압을 변하지 않게 유지하고 모터 조절 속도를 높이세요. 반죽의 비틀림은 단단하고 얇지만 길이는 변하지 않습니다.

2. 모터 조절 속도를 변하지 않게 유지하고 유압을 높이면 반죽의 꼬임이 느슨해지고 길이가 늘어납니다.

- 유압을 높이면 조절 모터의 속도가 빨라져 생산 효율이 향상됩니다.

- 생산 과정에서 틀을 채울 수 있을 만큼 충분한 반죽을 실린더에 보관해야 하며, 반죽 트위스트의 각 작은 가닥의 두께가 가득 차고 균일해 보입니다.

- 비틀기 기계를 시작하기 전에 반죽 실린더에 단단한 물체가 있는지 확인하고 철이나 기타 도구가 없어야 합니다. 그렇지 않으면 틀이 부서질 것입니다.

| 부조 | 이유와 해결책 |

| 컨베이어 벨트가 작동하지 않습니다 | 1. 스위치 손상. 2. 속도 조절 상자가 손상되었습니다. 3. 속도 조절 모터 손상 4. 전원이 들어오지 않음 |

| 컨베이어 벨트가 이탈함 | 조정 핸들 |

| 반죽의 꼬임이 칼날에 달라붙어요 | 오일이 적거나 없으면 연료 밸브를 엽니다. |

| 반죽의 꼬임 굵기가 고르지 못해요 | 곰팡이가 막혔어요 |

| 커터가 작동하지 않습니다. | 1. 전원이 들어오지 않음 2. 커터 스위치 손상 3. 타임 릴레이 손상 4. 솔레노이드 밸브 손상 5. 낮은 기압 |

튀김반죽의 비틀림 유지

- 윤활. 일주일에 한 번씩 각 기어와 체인에 오일을 추가하여 유압 오일 레벨이 정상인지, 식용 연료 탱크에 오일이 있는지 확인하십시오.

- 작업 후에는 다음 사용을 위해 금형, 컨베이어 벨트를 완전히 제거해야 합니다.

- 체인은 사용 기간이 지나면 늘어나서 특정 상황에 따라 체인의 견고성을 조정합니다.

튀김 반죽 트위스트 기계 FAQ

- 기계는 얼마나 많은 비틀림을 할 수 있습니까?

단일, 3, 6개의 비틀림을 만들 수 있습니다.

- 반죽의 꼬임 길이를 조절할 수 있나요?

예, 조정될 수 있습니다.

- 반죽을 비틀면 쉽게 풀리나요?

아니요, 금형으로 회전하면 쉽게 풀리지 않습니다.