この連続真空パック食品洗浄乾燥ラインは、あらゆる種類の食品加工工場で、加工された包装食品を洗浄および乾燥するのに適しています。このラインの能力は500kg/hから2t/hまであり、顧客の要件に応じてカスタマイズできます。この自動洗浄ラインを包装食品に利用することで、食品の外箱を油汚れのない清潔な状態に保つことができ、その後の梱包や輸送が容易になります。

なぜ真空パックされた食品を洗う必要があるのですか?

多くの包装済みスナックには、製造過程で食品の外側の包装に油汚れ、ジュース、パンくずなどの汚れがたくさん付いています。適時に洗浄または洗浄しないと、食品包装のジュースが劣化するだけでなく、刺激臭が発生するだけでなく、見た目も悪くなり、販売にも影響を及ぼします。真空包装食品洗浄乾燥プラントを使用すると、食品の外包装の表面からあらゆる種類の汚れを効果的に除去できます。

真空パック食品洗浄ラインのワークフロー

真空包装食品の洗浄乾燥ラインの設備には、主にすすぎ機、泡洗浄機、振動水分除去機、エア乾燥機、急速乾燥機が含まれます。この洗浄ラインの主な機能は、包装された食品の外箱に付着した油分や汚れを効果的に除去することです。

すすぎ機

包装された食品がすすぎ機に投入されると、食品パッケージに付着した油分や汚れが徐々に水に溶け込みます。製品に油が大量に付着している場合は、必要に応じて一定量の洗剤を追加できます。また、この洗浄工程において、包装された食品の袋が破れている場合には自動的に水面に浮かび上がりますので、顧客は商品の袋が破れていることを容易に選別することができます。このすすぎリンクにはスチーム加熱機能があり、洗浄槽内の水を加熱することができます。

泡洗濯機

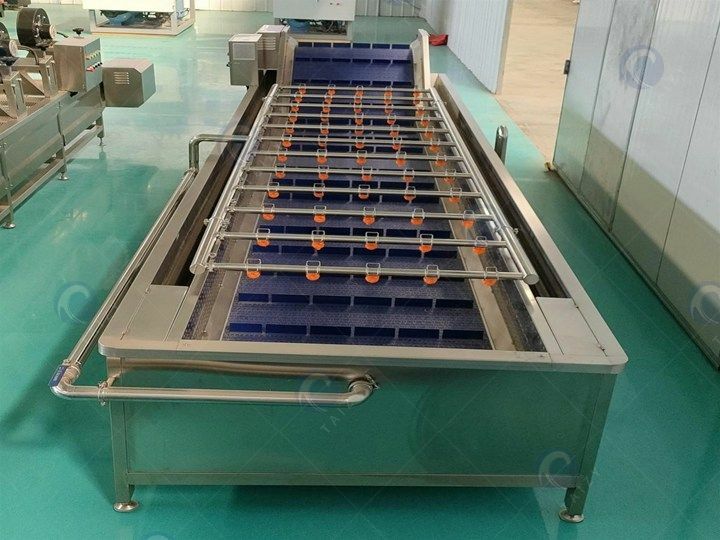

洗浄後、梱包された食品は次にバブル式野菜洗浄機へ移動して二次清浄を行います。機械の洗浄槽には槽の端部に複数の高圧水流が配置されており、清浄剤を連続的に衝撃して転がすように促します。機械の上部にはいくつかのシャワーヘッドがあり、真空パック食品をもう一度清浄します。

振動脱水機

洗浄された真空パックされた食品は、ベルトコンベアによって振動脱水機の上部まで運ばれます。この機械は、高周波振動により包装された食品の表面の水分の大部分を除去することができます。振動水分除去機のスクリーン表面は曲げとパンチングのデザインで、材料の前進に便利で、材料を損傷しません。本体底部には水受け皿が付いており、振動で排出された水を統一して再利用するのに便利です。

フリップ式エアードライヤー

このひっくり返し式エアドライヤーは、複数の強力ファンを使用して梱包食品を空中乾燥させることができ、大量の袋詰材料の連続空気乾燥に最適です。機械のコンベヤーベルトはひっくり返し式の設計で、搬送中には材が自動的に裏返されます。下部にはエアドライヤーには水受けトレイが設置されており、吹き飛ばされた水を一括リサイクルするのに便利です。

速乾性乾燥機

この連続多層乾燥機は、材料を迅速かつ完全に乾燥させるために使用されます。製品の乾燥に対する要求が高いお客様は、この乾燥機をお選びいただけます。本機は蒸気で加熱され、ベルトコンベア上に材料を均一に広げ、モータの駆動により入口側から出口側まで均一に搬送して乾燥工程を完了します。

真空パック食品洗浄プラントの主な特長

この連続洗浄ラインは、お客様の処理ニーズに合わせて機械構成をカスタマイズ可能です。お客様のニーズに合わせた機種と対応機器をご提案させていただきます。例えば、お客様の包装食品の清浄度に応じて、洗濯機の台数や連続乾燥機の必要性を推奨します。

この包装食品の洗浄・乾燥ラインのすべての機器は 304 ステンレス鋼で作られており、耐腐食性、磨耗性に優れており、洗浄中の包装食品を汚染することがありません。加熱機能付き機器の加熱方式は電気加熱とスチーム加熱の両方が可能です。

コメントを追加