豆腐は滑らかで美味しく、栄養価も高いです。豆腐の種類は世界中で人気があります。伝統的に、豆腐は手作りで作られてきました。現代技術の発展に伴い、多くの豆腐メーカーが自動豆腐製造機を採用して豆腐を製造しています。豆腐製造機は、手作業による生産の遅さという欠点を補っており、完成した豆腐の品質は手作り豆腐に劣りません。当社の自動豆腐製造機は、すでに日本で稼働しています。

豆腐製造機 注文詳細

この日本人のお客様は3回目のご協力です。 3年前、お客様は豆腐製造業を始められ、当社から小型の豆腐製造機を購入されました。 1年後、お客様は事業範囲を拡大し、当社から中型豆腐製造機を2台購入されました。今年もお客様は生産量を拡大し続け、当社から大規模な豆腐生産ラインを購入されました。現在は豆腐製造ラインを使って豆腐を生産している。

初めてご協力させていただく際、お客様は豆腐の製造工程を詳しく知りませんでした。私たちは豆腐製造機メーカーとして、このお客様と豆腐づくりの製造工程を共有しました。

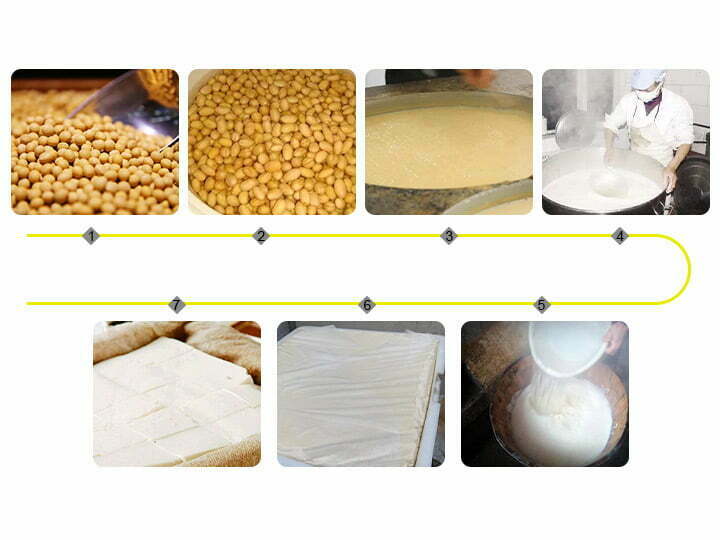

伝統的な豆腐の製造工程

伝統的な手作り豆腐の製造プロセスには、豆の選択、浸漬、粉砕、濾過、煮る、点在、成形が含まれます。

- 豆の選択:大豆だけでなく、緑豆、白インゲン豆、エンドウ豆なども選択して豆腐を作ることができます。豆腐を作るための豆は、カビのない全粒豆を使用する必要があります。

- 浸漬: 豆を浸す時間は時間とともに変更する必要があります。浸す水の質、温度、時間はすべて、最終的な豆腐の品質に影響します。

- 粉砕: 伝統的に、大豆を粉砕するのに石粉砕機が使用されます。大豆を挽くと豆乳とおからがにじみ出てきます。

- 濾過:豆腐の滑らかな味を確保するには、濾布を使用して豆乳に含まれる残留物を濾過する必要があります。最新の自動豆腐製造機は、豆乳とおからを粉砕するときに自動的にろ過します。

- 牛乳を沸騰させる:牛乳を沸騰させる過程で、豆乳の泡を消すために新鮮な油を加えます。

- 点滴:凝固剤の添加は豆乳を固める最も重要なステップです。凝固剤は通常、豆乳を混合する際に凝固剤を添加する際に使用されます。

- 成形:濾布を敷いたトレイに点状豆腐を入れ、所定の押し物を使って押します。 5分ほど放置すると豆腐が出来上がります。

以上が伝統的な手作り豆腐の製造工程です。豆腐の自動製造機は粉砕から成形までの全工程を実現します。豆腐製造機は日本だけでなく世界中で人気があります。

日本の豆腐の製造工程

このお客様との2回目の協力で、彼が伝統的な豆腐と日本の豆腐を作るために小型豆腐製造機を使用していることを知りました。日本の豆腐の製造工程は、伝統的な豆腐の製造工程と似ています。日本の豆腐は、最初に煮てから濾過する調理済みミルク豆腐の一種です。

その他、千葉豆腐、木綿豆腐、湯葉、干豆腐などの豆腐製品も販売されています。豆腐作りをベースに改良された大豆製品です。

コメントを追加