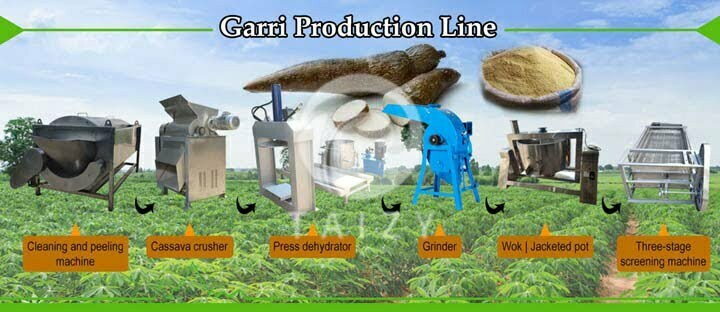

Garri processing machine is used to get garri from cassava, and the whole processing is rather complicated. Garri, also know as gari, is a common food in Africa markets with good taste, and it is portable when people go out, that is why most people consider garri as daily food. During the whole garri production line, six machines are needed, that is, cassava peeling and washing machine, cassava crushing machine, hydraulic pressing machine, crusher machine and screening machine. I will introduce them for you one by one.

Cassava cutting and washing machine

It mainly peels the skin of cassava and then fully wash them. As we all know, its skin contains hydrocyanic acid that is poisonous, the brush made of steel can completely peel skin. Finally, the rotation screen discharge them with high speed. The cleaning and peeling rate are very high, which means that the final cassava is very clean.

| Model | GD-PL-150 |

| Size | 2200*1300*1000mm |

| Voltage | 2.2KW |

| Power | 380v50Hz |

| Capacity | 500kg-1T/H |

Cassava crusher machine

Cassava crusher machine is equipped with two rollers with different shapes and different rotation speeds, and it can crush cassava into small pieces.

| Model | GD-PS-300 |

| Size | 1150*700*1200mm |

| Voltage | 380v50Hz |

| Power | 11.75KW |

| Capacity | 1T/H |

Hydraulic pressing machine

Hydraulic pressing machine is used to remove the water contained in the crushed cassava. Before pressing, you should put them into the bag, then place it to the pressing barrel. After several minutes, the user can take out the bag. In addition, pressed water is able to be used to extract starch, which is the main difference between gari processing and starch processing.

| Model | GD-HP-600 |

| Size | Frame: 1300*1800*700

The diameter of barrel:900mm Length:1100mm |

| Voltage | 380V50Hz |

| Power | 4KW |

| Capacity | 100-300Kg/H |

At this time, it is necessary to ferment bagged cassava slurry for around 24 hours.

Crushing machine

During the garri production line, cassava needs to be crushed twice; fist crushing just gets crude cassava pieces, but the second crushing is to get fine cassava powder. This crusher machine is equipped with hammers that can fully beat the cassava pieces into powder.

| Model | 9FQ-320 |

| Size | 350*550*850mm |

| Voltage | 380V50Hz |

| Power | 3KW |

| Capacity | 100-300Kg/H |

Fryer machine

Fryer machine also plays an important role during gari processing machine. It can stir cassava powder in order to uniform heating, and the heating temperature is around 40-50℃. After frying, the toxic substance will evaporate, so this step is very essential. What’s more, fried garri tastes good than before.

| Model | GD-RF-1200 |

| Size | 2500*1400*1600mm |

| Voltage | 380v50Hz |

| Power | 1.5KW |

| Capacity | 100Kg/H |

Screening machine

Finally, users shall use screening machine to separate crude cassava powder to get fine fried cassava powder that can be eaten directly in daily life. There are there screens, and the bottom screen is thinner than the other screens. Normally, gari is very easy to store and portable, and people prefer to mix gari with hot or cold water.

| Model | |

| Size | 1000*2500*850mm |

| Voltage | 380V50Hz |

| Power | 2.2KW |

| Capacity | 500Kg/H |

If you want to save cost to make cassava flour, you can use your cooking pan to fry the cassava powder instead of frying machine; or peel and wash cassava manually. However, the working efficiency will greatly decrease.

Advantage of Garri processing machine

- All the garri processing machine are made stainless stain with rather a long service life.

- The machine is easy to operate and maintain.

- The processed garri(gari) can mix with cold or hot water, and it is portable for people in daily life.

- As for cassava peeling and washing machine, its peeling rate is very high, and most cassava can be fully peeled.

- Two rollers with different shape are able to completely crush the cassava into small pieces.

- This garri production line bears low cost and high benefit.

The successful case of Garri processing machine

The customer from Sierra Leone sent an inquiry to us about garri(gari) production line. He has big cassava farmland and wants to buy the machines that can process cassava into garri. We sent picture, video as well as professional quotation for him. Influenced by our sincere attitude and professional skills, he has already paid the deposit, and we are preparing the machines of garri production line now.

We also have starch processing machine, and it is more complicated with gari processing. You can ask us to know more!

FAQ of Garri processing machine

- What is the peeling rate?

Around 70%-80%.

- What the pressed water can be used for?

It can be used to extract starch.

- What is the heating temperature of the frying machine?

About 40-50℃.

- Can I peel the cassava and fry cassava powder manually?

Yes, you can, but it greatly decreases the working efficiency.