The complete fruit vegetable washing plant has the main functions of continuous vegetable washing, drying, and packing. This automatic vegetable washing plant can be used for processing all kinds of fruits and vegetables, especially suitable for processing various root vegetables, such as potatoes, taro, tomatoes, cucumbers, peppers, etc. The processing capacity of this cleaning line is generally between 300kg/h and 3t/h. Currently, most of our customers choose this machine for washing tomatoes, potatoes, and jalapeno peppers.

Why choose the vegetable washing line?

For the family, fruit and vegetable washing is generally hand-washing can be used. But for many restaurants, supermarkets, fruit and vegetable processing plants, and fruit and vegetable farms, it is often uneconomical to hire workers to wash large quantities of vegetables. This is because of the high cost of workers and the low cleaning efficiency. Therefore, purchasing automatic fruit and vegetable washing and processing lines to replace manual vegetable washing has become the choice of more fruit and vegetable processors.

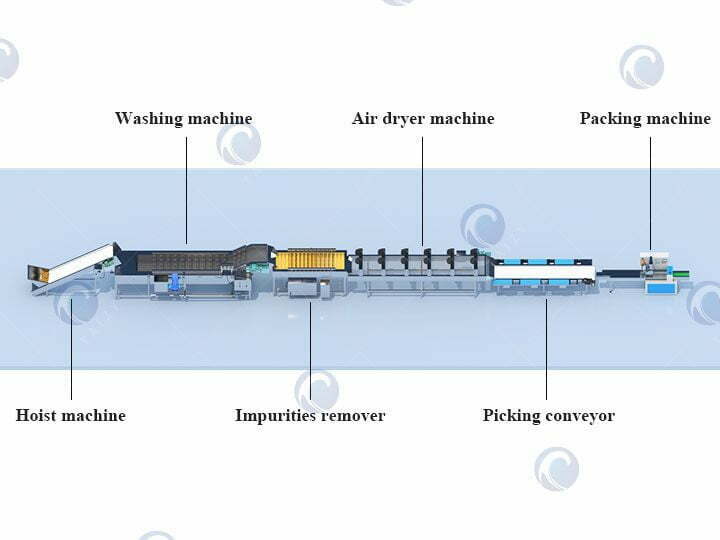

Main equipment of the automatic fruit vegetable washing plant

This complete set of fruit and vegetable washing equipment mainly includes an automatic lifting machine, bubble washing machine, impurity removal machine, airflow air dryer, and continuous packing machine. Usually, our factory can design specific cleaning line solutions for customers according to their specific material and processing needs.

Automatic hoist machine

The lifter machine is used to lift fruits and vegetables into the washing machine automatically, which can save manpower. The height and width of the elevator can usually be customized according to the customer’s processing needs. In addition, the conveying speed of the elevator can be adjusted.

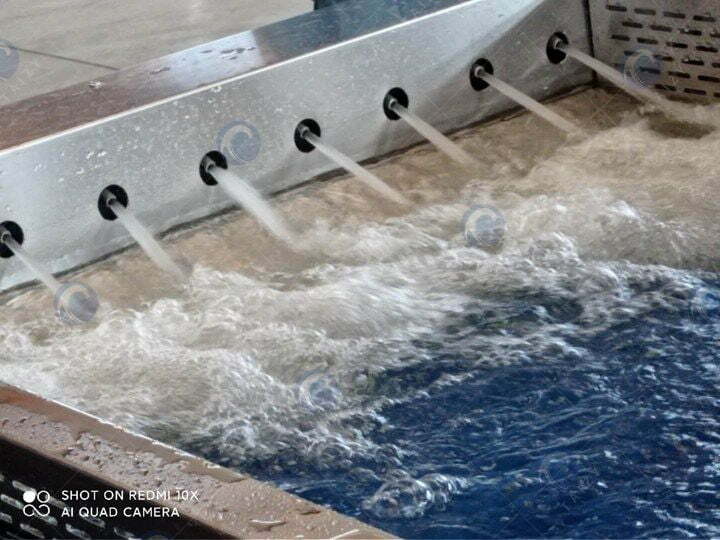

Bubble washing machine

This new fruit and vegetable washing machine with an automatic surfing function can not only push the material forward when cleaning the material but also make the material roll continuously during the cleaning process to improve the cleaning efficiency.

Impurity remover machine

Hair roller impurity removal machine can clean the surface of the cleaned fruits and vegetables not easy to be cleaned off the hair, sand, stones, etc. for further cleaning. The machine can be replaced with different hardness and length of hair rollers according to different fruits and vegetables. When cleaning fruits and vegetables will not cause damage to the surface of fruits and vegetables.

Air dryer machine

This continuous air dryer is mainly used for fast air drying of cleaned fruits and vegetables. The purpose of air drying is to remove water droplets from the surface of fruits and vegetables for subsequent stages of fruit and vegetable packaging. The conveyor belt of the new air dryer has been upgraded to a roller bar conveyor for higher air drying efficiency.

Picking table

This picking table is a conveyor platform with multiple workstations. Workers can stand at the corresponding stations and manually pick the cleaned fruits and vegetables, picking out those that are defective or spoiled. After sorting, these clean fruits and vegetables can enter the packaging process.

Vegetable packaging machine

The continuous pillow wrapping machine is the last part of this fruit and vegetable washing line for the individual packaging of fresh vegetables. This multi-functional packaging machine can realize different forms of packaging for fruits and vegetables, such as bagging, boxing, etc.

Features of Taizy fruit vegetable washing plants

- This commercial fruit and vegetable washing, drying, and packaging line is very versatile. It can be used to clean all kinds of fruits and vegetables. Currently, this industrial fruit and vegetable washing equipment is commonly used in farm estate planting, vegetable processing factories, restaurant chain centers, supermarkets, large canteens, etc.

- As a professional manufacturer and supplier of food processing machinery, Taizy factory has been exporting various types of food processing equipment to customers in more than 60 countries and regions for 10 years. Among them, the export volume of fruit and vegetable washing equipment accounts for about 37.9%. At present, our fruit and vegetable washing and processing lines are most frequently exported to Thailand, Canada, the USA, Mexico, Qatar, Turkey, Indonesia, Saudi Arabia, Australia, Aruba, Egypt, etc.

- Our factory provides a full range of one-stop services and can customize the right fruit and vegetable cleaning solution for customers according to their raw materials, processing needs, investment budget, and factory area. We provide One-stop and turnkey production line solutions. The common processing capacity of the vegetable washing machine line has 500 kg/h, 1000kg/h, 2000kg/h, and 3000kg/h.

1000kg/h green jalapeno pepper washing machines shipped to Mexico

Recently, we have again exported to Mexico a complete pepper washing line with a processing capacity of 1000 kg per hour. The customer has a large vegetable growing circle and grows a lot of green jalapeno peppers. previously, the customer had to hire a lot of workers to clean jalapeno peppers during the harvest season, which was costly and inefficient.

With the rapid growth of the purification market, the customer also intended to purchase a purification line to process the fruits and vegetables on their farm. After this line, the customer’s green jalapeno peppers can be sold directly to local supermarkets, retail stores, restaurants, etc.

Machine details of Mexican order for green jalapeno peppers washing plant

| Item | Parameter | Qty |

1. Conveyor  | Model: TZ-1200 Size: 2200*800*1600mm Voltage:380v,50hz, 3phase Power:0.37kwWeight : 280kg Conveyor belt width: 800mm Material: 304 stainless steel +PVC belt | 1 set |

2. Bubble washer machine  | Model: TZ-5000 size:5000*1600*850mm Voltage:380v,50hz, 3phase Power:6.7kw Weight: 1000kg Conveyor belt width: 800mm Material: 304 stainless steel Notes: Includes surf function, can push raw material forward. Second cleaning function. Water filter and recycle function. Includes reduce motor, can adjust belt speed. | 1 set |

| 1. The equipment is made of 304 stainless steel with a thickness of 2MM. 2. The frame is made of 304 stainless steel of 50 * 50 * 2MM. 3. The equipment has adjustable feet and a removable universal wheel for easy transportation. | ||

3. Dryer  | Model: TZ3000 Voltage: 380v,50hz, 3phase Power:4.5kw Weight:600kg Capacity:1000kg/h Size:3500*1100*1550mm Material: 304 stainless steel Mesh belt: 800mm1 motor control belt 8 fan motors | 1 set |

| 1. The equipment is made of 304 stainless steel with a thickness of 2MM. 2. The frame is made of 304 stainless steel of 60 * 40 * 2MM. 3. The equipment has adjustable feet and a removable universal wheel for easy transportation. | ||

4. Picking conveyor  | Model: TZ-1000 Size:3500*1000*900mm Voltage: 380v,50hz, 3phasePower: 0.37kw Weight : 280kg Conveyor belt width: 600mm Side width: each side 300mm Material: 304 stainless steel +PVC belt | 1 set |

| Notes: 1. warranty: 2 years. 2. production time: 15-25 days. 3. Payment term: 30% deposit, 70% balance before delivery. 4. Price valid time: 30th, July 2022. 5. Quality Guarantee Terms: A. The seller guarantees the machine and its accessories are new, the guarantee period for this machine is 1 year from the date machine arrives buyer’s place. B. During the quality guarantee period, any problems caused by incorrect operation by the buyer, the seller provides a free skill maintenance service. The seller offers forever technical service and spare parts at a cost price. If need a drawing layout, we can design it for you. |

Green pepper washing machine line working video

Related equipment recommendations for fruits and vegetables washing plants

For large fruit and vegetable processing plants, a large number of plastic frames are often used for storing and transporting fruits and vegetables. So how do you dispose of and reuse these plastic frames when they get dirty? Our factory can provide this automatic basket washer that can quickly clean and disinfect dirty plastic baskets. If you happen to need it, please feel free to consult us.

Parameters of the plastic baskets washing machine

Size: 6100*1900*2300mm

Voltage: 415v/50hz, 3 phase

Weight: 700kg

Material: 304 stainless steel

Capacity: about 200-500pcs/h, if basket more cleaner, can reach 700-800pcs/h

Tray size: 60-80cm; 60-40cm

Add Comment