Die kommerzielle Wasch- und Trocknungssortierlinie für Obst und Gemüse wird hauptsächlich zur Automatisierung der Verarbeitung großer Mengen Obst und Gemüse eingesetzt. Nach einem vollständigen Verarbeitungsprozess in weniger als 10 Minuten können die Früchte und Gemüse direkt vom Bauernhof an den Supermarkt verkauft werden. Die Wasch- und Sortierlinie für Obst und Gemüse kann alle Arten von Obst und Gemüse verarbeiten, Verunreinigungen effektiv beseitigen, schlechte Früchte aussortieren und sie automatisch für die Verarbeitung sortieren und verpacken. Die Verarbeitungskapazität der automatischen Obst- und Gemüsewasch-, Trocknungs- und Sortierlinie liegt im Allgemeinen zwischen 500 kg/h und 5000 kg/h. Unsere Fabrik kann kostengünstige Verarbeitungsanlagen an die spezifischen Bedürfnisse und Rohstoffe unserer Kunden anpassen.

Warum sollten Sie sich für Gemüsewasch- und Trocknungssortierlinien entscheiden?

Große Marktnachfrage nach sauberem Gemüse

Obst- und Gemüsesupermärkte, große Kantinen und Lebensmittelverarbeitungsbetriebe haben heute einen sehr hohen Bedarf an sauberem Gemüse. Aus diesem Grund verkaufen viele Obst- und Gemüsebauernhöfe ihre frisch geernteten Obst- und Gemüseprodukte nicht mehr direkt auf dem Markt, sondern nutzen Obst- und Gemüseverarbeitungsgeräte, um das Obst und Gemüse zu sauberem, gut verpacktem Gemüse zu verarbeiten. Diese Verarbeitungsmethode von Kakao erhöht die Wertschöpfung von Obst- und Gemüseprodukten erheblich und erfreut sich auf dem Markt größerer Beliebtheit.

Hohe Verarbeitungseffizienz und geringere Kosten

Im Vergleich zur Einstellung vieler manueller Arbeitskräfte für die Verarbeitung von Obst- und Gemüseprodukten kann der Kauf eines vollständigen Satzes von Verpackungslinien zum Waschen, Trocknen und Sortieren von Obst und Gemüse die Verarbeitungseffizienz erheblich verbessern und die Kosten für viele Arbeitskräfte senken.

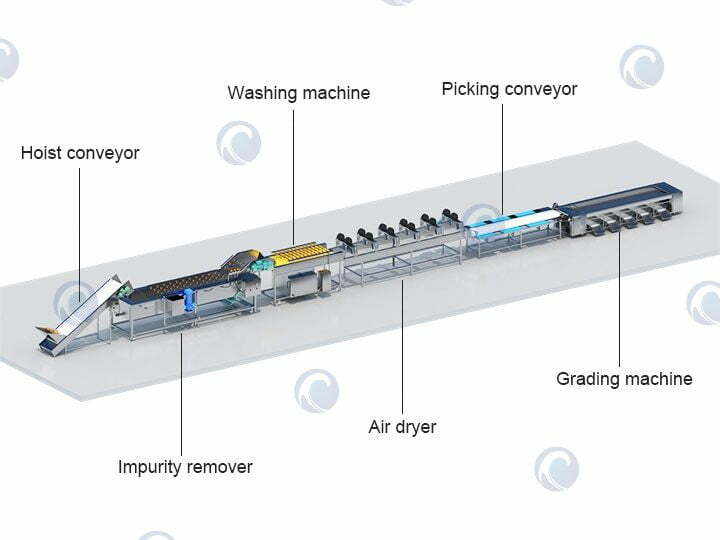

Details zur Sortierlinie zum Waschen und Trocknen von Obst und Gemüse

Das Design der Obst- und Gemüseverarbeitungslinie kann im Allgemeinen auf alle Arten von Lebensmittelverarbeitungsbetrieben, Obst- und Gemüsesupermärkten, Restaurants usw. zur Verarbeitung aller Arten von Obst und Gemüse angewendet werden. Die Hauptausrüstung dieser Produktionslinie ist eine automatische Hebemaschine, eine Blasenwaschmaschine, eine Maschine zur Entfernung von Verunreinigungen, ein Lufttrockner, ein Pflücktisch, eine automatische Sortiermaschine für Obst und Gemüse, eine Verpackungsmaschine für sauberes Gemüse usw.

Schritte zur Verarbeitung von sauberem Gemüse und Obst

Heben der Rohstoffe

Zunächst müssen wir das zu waschende Gemüse oder Obst nacheinander in den automatischen Aufzug geben. Der Elevator transportiert sie zur Reinigung mit gleichmäßiger Geschwindigkeit zum Blasenwäscher. Die Fördergeschwindigkeit des Elevators kann je nach Verarbeitungsbedarf angepasst werden.

Waschen von Gemüse und Obst

Der Vortex-Generator unter dem Reinigungstank der Luftblasenwaschmaschine erzeugt eine große Anzahl von Blasen im Wasser zur schnellen Reinigung von Obst und Gemüse. Am Ende der Blasenspülmaschine befindet sich auch eine Surfeinrichtung, die das Material kontinuierlich vorwärts rollen lässt. Der Reinigungsprozess verursacht keine Beschädigung des Rohmaterials.

Entfernen von Verunreinigungen

Nach der Reinigung mit der Blasenwaschmaschine kann eine Maschine zur Entfernung von Verunreinigungen zur weiteren Reinigung von Obst und Gemüse usw. verwendet werden. Diese Maschine zur Entfernung von Verunreinigungen verfügt über mehrere Haarwalzen, mit denen die Oberfläche von Obst und Gemüse, die schwer zu reinigen sind, gereinigt werden kann die Haare oder Sand und Steine.

Lufttrocknung

Der Lufttrockner verfügt über mehrere Sätze leistungsstarker Ventilatoren, um die Wassertropfen auf der Oberfläche von Obst und Gemüse schnell zu trocknen. Nach der Lufttrocknung können die Früchte und Gemüse weiter verpackt oder sortiert werden.

Saubere Sortierung von Obst und Gemüse

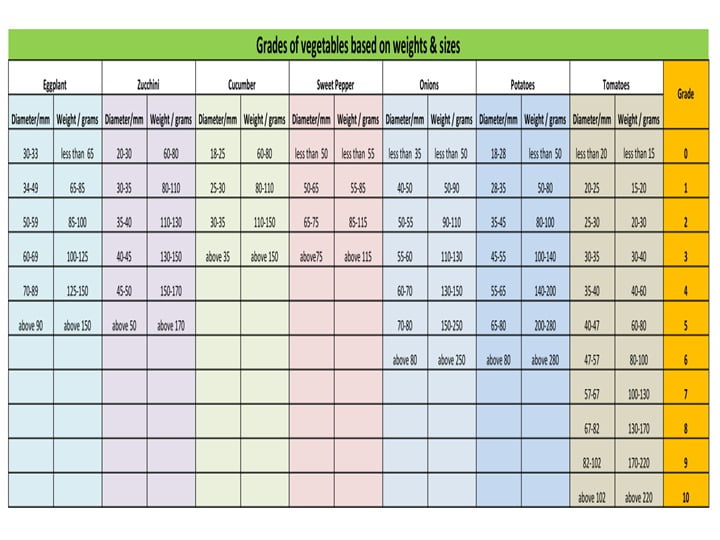

Der automatische Sortierer kann sauberes Obst und Gemüse nach verschiedenen Sortiermaßen wie Gewicht, Durchmesser und Größe sortieren. Nach der Sortierung können die Kunden das zum Verkauf stehende Obst und Gemüse in verschiedenen Größen sortieren und kennzeichnen. Der Sortiergrad der Sortiermaschine kann individuell an die Bedürfnisse des Kunden angepasst werden.

Schnelle Verpackung

Kunden können auch unsere Obst- und Gemüseverpackungsmaschine wählen, um das sortierte Obst und Gemüse entsprechend ihren Bedürfnissen zu verpacken. Obst und Gemüse können in Vakuumverpackungen, Karton- und Beutelverpackungen, Schrumpffolienverpackungen usw. verpackt werden.

Klassifizierung von Obst- und Gemüsesortiermaschinen

Als sehr kompetenter Hersteller und Lieferant von Lebensmittelmaschinen können wir unseren Kunden eine große Auswahl an Geräten zur Obst- und Gemüsesortierung anbieten. Es gibt zwei Haupttypen von Obst- und Gemüsesortiermaschinen, die von unserem Werk verkauft werden: Sortieren nach Durchmesser und Sortieren nach Gewicht.

Sortierung von Gemüse und Obst nach Durchmesser

Typ 1

Diese Obst- und Gemüsesortiermaschine vom Rollenstangentyp wird üblicherweise zum Sortieren aller Arten von Blumenzwiebeln wie Kartoffeln, Taro, Süßkartoffeln, Tomaten, Äpfel, Zwiebeln, Granatäpfel usw. verwendet. Die Sortierzahl dieser Sortiermaschine kann je nach Kundenwunsch angepasst werden Anforderungen, in der Regel 4-7 Klassen. Bei der Sortierung fallen die Früchte und Gemüse automatisch in die entsprechende Austragsdurchmesserklasse, wenn sie den Spalt zwischen den entsprechenden Überrollbügeln erreichen.

Video zur Kartoffelsortiermaschine

Typ 2

Dieser neuartige Obst- und Gemüsesortierer sortiert Obst und Gemüse auch nach seinem Durchmesser. Es wird häufiger zum Sortieren aller Arten von Früchten wie Orangen, Blaubeeren, Pflaumen, Heiligenfrüchten, Kiwis, Weißdorn, Datteln usw. verwendet. Der Sortierzylinder des Sortierers besteht aus PE-Kunststoff und sein Öffnungsdurchmesser kann individuell angepasst werden. Die Bewertungsnote dieser automatischen Sortiermaschine liegt normalerweise zwischen 4 und 9 Noten.

Sortierung von Gemüse und Obst nach Gewicht

Diese kontinuierliche Obst- und Gemüsesortiermaschine ist nach Gewicht sortiert. Diese industrielle Sortiermaschine kann zum Sortieren aller Arten von Obst und Gemüse mit hoher Sortiereffizienz verwendet werden. Die Sortiermaschine wird normalerweise mit einem automatischen Obstpflücker-Ladegerät verwendet. Die Obstsortiermaschine verfügt über eine automatische Wiegefunktion, die eine genaue Gewichtssortierung von Obst und Gemüse ermöglicht.

Allgemeine Referenz zur Obst- und Gemüsesortierung

Empfohlene Maschine für die Sortierlinie zum Waschen und Trocknen von Obst und Gemüse

Reinigungsmaschine für Gemüsepackungen

Mit dieser kontinuierlichen Verpackungsmaschine kann sauberes Gemüse in Beutel oder Kartons verpackt werden. Größe und Gewicht der Obst- und Gemüseverpackung können je nach Kundenwunsch eingestellt werden.

Reinigungsmaschine für Plastkörbe

Diese industrielle Kunststoffkorbwaschmaschine kann Arbeitskräfte für alle Arten von Kunststoffkörben in Obst- und Gemüseverarbeitungsbetrieben zur schnellen Reinigung und Hochtemperatursterilisation ersetzen.

Anwendungen von Gemüseverarbeitungsanlagen

Der komplette Satz von Obst- und Gemüseverarbeitungsanlagen wird mittlerweile in vielen Bereichen eingesetzt, beispielsweise bei Tiefkühlgemüseverarbeitern, Supermarktkettenlieferanten, Obst- und Gemüseanbauern usw. Heutzutage haben wir in viele Länder und Regionen exportiert. Wir haben unser Obst exportiert und Gemüsewasch- und Sortierlinien in viele Länder und Regionen, wie Ägypten, Kanada, Türkei, Vereinigtes Königreich, Italien, Frankreich, Kanada, USA, Katar, Frankreich, Griechenland, Indonesien, Saudi-Arabien, Australien usw.

3-5t/h Tomaten und Zucchini Wasch- und Trocknungssortierlinie in die Türkei geliefert

Das Werk in Taizy hat kürzlich eine komplette Obst- und Gemüseverarbeitungslinie mit einer Kapazität von 3 bis 5 Tonnen pro Stunde in die Türkei exportiert. Der Kunde besitzt eine große Obst- und Gemüseplantage und kaufte die Linie hauptsächlich zur Verarbeitung von Tomaten, Zucchini, Kartoffeln, Zwiebeln, Auberginen, Gurken und Paprika. Zu den Verarbeitungsstufen der Linie gehören Waschen, Trocknen, Sortieren und Verpacken.

Parameter einer Gemüseverarbeitungsanlage für die Türkei

| Artikel | Parameter | Einheit |

| 1. Förderer | Modell: TZ-1500 Gewicht: 160 kg Leistung: 1,1 kW Größe: 1800 * 900 * 1200 mm Spannung: 415 V/50 Hz, 3 Phasen | 1 Satz |

| 2. Blasenwaschmaschine | Modell: TZ-8000 Spannung: 415 V/50 Hz, 3 Phasen Gewicht: 2000 kg Leistung: 10,5 kW Größe: 8000 * 1500 * 1300 mm Material: Edelstahl 304 Surffunktion hinzufügen, Rohmaterial vorantreiben | 2 Sätze |

| 3. Lockenwickler-Entferner | Modell: TZ-2000 Spannung: 415 V/50 Hz, 3 Phasen Gewicht: 1200 kg Leistung: 2,2 kW Größe: 6000 * 1400 * 1200 mm Rollen (weich): 48 Stück mit Abdeckung | 1 Satz |

| 4. Luftkühlmaschine | Modell: TZ-3000 Spannung: 415 V/50 Hz, 3 Phrasen Leistung: 13,2 kW Gewicht: 2000 kg Größe: 8000 * 1500 * 1600 mm Material: Edelstahl 304 Anzahl der Lüfter: 16 Stück Hinweise: Fügen Sie die Gebläsefunktion hinzu | 1 Satz |

| 5. Kommissionierband | Modell: TZ-2500 Spannung: 415 V/50 Hz, 3 Phasen Leistung: 0,75 kW Gewicht: 300 kg Größe: 4000 * 700 * 900 mm | 1 Satz |

| 6. Bilaterale Sortiermaschine | Modell: TZ-250 Sortiergeschwindigkeit: 10000 Stück/Stunde Spannung: 415 V/50 Hz, 3 Phasen Sortierintervall: 20-1500 Gramm Leistung: 1,85 kW Auswahl Maschinengröße: 7400*1800*1200mm Feedergröße: 2100*800*1200mm Gewicht: 1100 kg Material: Edelstahl 304 Klassenstufe: 10 Stufen Sortieren: nach Gewicht Rohstoff: Tomate, Kartoffel, Zwiebel, Paprika | 3 Sätze |

| 7. Sortiermaschine | Modell: TZ-800 Spannung: 415 V/50 Hz, 3 Phasen Leistung: 1,1 kW Größe: 8000*1400*800mm Kapazität: 3-4 t/h. Sortierung: nach Durchmesser Rohstoff: Gurke (4 Ebenen), Zucchini (6 Ebenen), Aubergine (6 Ebenen) | 3 Satz |

| 8. Korbwaschmaschine | Modell: TZ-300 Größe: 6100 * 1900 * 2300 mm Spannung: 415 V/50 Hz, 3 Phasen Gewicht: 700 kg Material: Edelstahl 304 Kapazität: ca. 200–500 Stück/h, wenn der Korb sauberer ist, können 700–800 Stück/h erreicht werden Tablettgröße: 60 x 80 cm; 60 x 40 cm. Extra 10 Stück, Sprinklerkopf kostenlos Hinweise:1. Alles mit SUS 3042 besprühen. Regulierung der Frequenzumwandlungsgeschwindigkeit3. 3 Wassertanks, 2 Heizwassertanks, 1 Klarwassertank4. 3 Wasserpumpen aus Edelstahl5. 2 Sätze Entwässerungsventilatoren6. Der Entwässerungs- und Überlaufablauf ist als Edelstahl-Entwässerung vereint | 1 Satz |

| 9. Kissenverpackungsmaschine | Modell: TZ-250 Spannung: 415 V, 50 Hz, 3 Phasen Leistung: 2,5 kW Verpackungsgeschwindigkeit: 40-230 Stück/min Die Produkte sind hoch: 5–40 mm Membranbreite: ≤250 mm Verpackungshöhe: 5–60 mm Größe: 3770 * 670 * 1450 mm Gewicht: 800 kg Im Preis inbegriffen: Stickstoffspülsystem, Druckdatumsfunktion. Dichtungsklingen: 3 Stk | 1 Satz |

Kommentar hinzufügen