Die Kakaobohnenverarbeitungsmaschine von Kakaobohnen zu Kakaonibs zielt darauf ab, Kakaobohnen zu Kakaonibs zu verarbeiten. Dies ist der Front-End-Verarbeitungsprozess von Kakaobohnen. Zu diesen Maschinen zur Verarbeitung von Kakaobohnen gehören hauptsächlich Maschinen zum Zerteilen von Kakaofrüchten, Maschinen zum Entfernen von Steinen, Maschinen zum Rösten von Kakaobohnen, Schälmaschinen, Siebmaschinen, Lagerbehälter und andere Maschinen. Diese Kakaobohnenverarbeitungsmaschinen zeichnen sich durch eine hohe Produktionseffizienz, eine große Verarbeitungsleistung und eine einfache Bedienung aus. Sie sind die besten Applikationsmaschinen für Kakaobohnenverarbeitungsbetriebe.

Über Kakaonibs

Kakaonibs sind verarbeitete Kakaobohnenstücke. Obwohl Kakaobohnen klein sind, haben sie einen starken Schokoladengeschmack. Daher wird es normalerweise zur Herstellung von Schokolade verwendet. Auch der Zuckergehalt in Kakaonibs ist deutlich geringer als in anderen Schokoladenprodukten. Daher ist es für viele Schokoladenliebhaber zu einem gesunden Ersatz geworden. Darüber hinaus sind Kakaonibs reich an Nährstoffen, die sich positiv auf die menschliche Gesundheit auswirken.

Video zur Bedienung der Kakaonibs-Verarbeitungsmaschine

Kakaobohnen-Verarbeitungsmaschine im Kakaonib-Verarbeitungsprozess

Maschine zum Knacken von Kakaofrüchten

Mit der Kakaofrucht-Spaltmaschine werden frisch geerntete Kakaobohnen geschält. Frische Kakaobohnen sind in eine harte Schale eingewickelt, was bestimmte Werkzeuge erfordert, um die Kakaobohnen auseinanderzubrechen. Die Kakaofruchtöffnungsmaschine hat die Funktionen Öffnen und Sieben. Es kann frisch gebrochene Kakaobohnen in verschiedene Sorten sieben. Darüber hinaus kann die Schale kontinuierlich aufgebrochen werden und die Effizienz beim Aufbrechen der Schale ist hoch. Nach dem Aufbrechen der Kakaofrucht müssen auch die frischen Kakaobohnen fermentiert werden, um braune, reife Kakaobohnen zu bilden.

Steinentfernungsmaschine

Dieser Schritt dient dazu, Steine und andere Verunreinigungen aus den Kakaobohnen zu entfernen. Dieser Steinentferner wird häufig in Körnern eingesetzt, um Verunreinigungen zu entfernen. Es kann Steine, Glas und andere Fremdkörper effektiv von Kakaobohnen trennen.

Maschine zum Rösten von Kakaobohnen

Die Kakaobohnenröstmaschine kann die Kakaobohnen durch Heizmethoden wie Elektroheizung oder Gasheizung bis zur Reife rösten. Die Kakaobohnenröstmaschine verfügt über zwei Modelle: Trommelröstmodell und Tunnelröstmodell. Die Wahl der Kakaoröstmaschine kann entsprechend der Röstleistung des Kunden getroffen werden. Die Trommel-Kakaoröstmaschine kann in einem einzigen Topf etwa 100 kg backen. Wenn Sie die Produktionsleistung erweitern möchten, können wir für Sie mehrere Backtöpfe zu einem einzigen Topf verbinden.

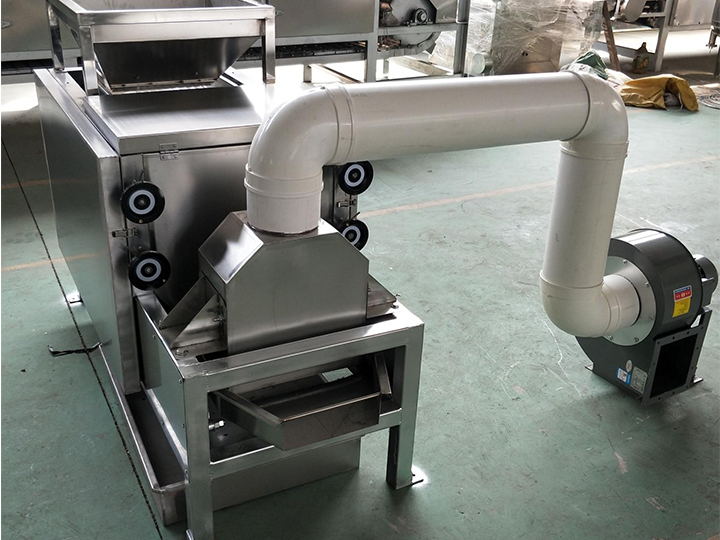

Kakaobohnen-Schälmaschine

Nach dem Rösten und Abkühlen lässt sich die Außenhaut der Kakaobohnen ganz einfach mit der Kakaobohnen-Schälmaschine entfernen. Die Kakaobohnen-Schälmaschine nutzt drei Gummiwalzen, um die Kakaobohnen zum Schälen in das Silo zu pressen. Die durch die Gummiwalze gepressten Kakaobohnen und das Reiben mit unterschiedlicher Geschwindigkeit werden in Kakaonibs zerkleinert. Und die Maschine kann auch mit einem Staubsauger ausgestattet werden, um die geschälten Kakaonibs aufzufangen. Kakaobohnen-Schälmaschinen zeichnen sich durch einen hohen Automatisierungsgrad, eine hohe Schälgeschwindigkeit und einen geringen Geräuschpegel aus.

Sortiermaschine für Kakaonibs

Nach dem Schälen durch die Schälmaschine erhält man Kakaonibs. Wenn Sie Kakaonibs mit der gleichen Partikelgröße erhalten möchten, müssen Sie zum Sieben eine Kakaonibs-Siebmaschine verwenden. Die Kakaonibs-Siebmaschine ist eine Trommelsiebmaschine, die Kakaonibs je nach Siebanforderungen in 3, 4, 5 und mehrere Sorten sieben kann.

Lagersilos

Nach dem Sieben der Kakaonibs kann das Gerät mit einem Hebezeug und einem Silo ausgestattet werden, um Kakaonibs unterschiedlicher Qualität zu lagern. Anschließend können Sie mit der Verpackungsmaschine Kakaonibs unterschiedlicher Größe verpacken. Das Lagersilo ist eine Vorrichtung zur Lagerung von Kakaonibs. Die Lagermenge kann durch die Fläche des Silos bestimmt werden.

Merkmale der Kakaobohnenverarbeitungsmaschine

- Die Kakaonibs-Verarbeitungsmaschine ist nur ein Teil der Kakaobohnenverarbeitung. Die Kakaobohnenverarbeitungsmaschine kann Kakaobohnen auch zu Kakaobutter, Kakaopulver, Schokolade und anderen Produkten verarbeiten.

- Die Kakaobohnenverarbeitungslinie verfügt über einen hohen Automatisierungsgrad und eine große Produktionsleistung, die für große Kakaobohnenverarbeitungsanlagen zur Verarbeitung von Kakaobohnen geeignet ist

- Darüber hinaus bieten wir auch maßgeschneiderte Kakaobohnenverarbeitungsmaschinen an. Es umfasst nicht nur Produktionsanpassungsdienste, sondern auch Maschinendesign, Maschinenplatzierungslösungen usw.

- Die Produktionslinie zur Verarbeitung von Kakaonibs kann je nach Kundenwunsch den erforderlichen Siebgrad erreichen.

- Alle Kakaobohnenverarbeitungsmaschinen zeichnen sich durch einen hohen Automatisierungsgrad, einfache Bedienung und geringe Geräuschentwicklung aus.

Parameter der automatischen Kakaobohnenverarbeitungsmaschine

| Name | Bild | Parameter |

| Kakaofruchtspalter |  | Kapazität: 800 kg/h Leistung: 1,1 kW Spannung: 380 V 50 Hz Abmessungen: 3 1.32m |

| Steinentfernungsmaschine |  | Kapazität: 1-3 Tonnen/Stunde Spindelgeschwindigkeit: 485 U/min Neigungswinkel zur Steinplatte: 10-14 Grad Effektiver Arbeitsbereich: 970×510 Ausgewählte effektive Arbeitsgröße der Platte: 160×65 Leistung: 0,55 kW Passende Lüfterleistung: 3 kW |

| Maschine zum Rösten von Kakaobohnen |  | Abmessungen: 4500×2900×1750 Motorleistung: 5,5 kW Leistung des Elektroofens: 112,5 kW Leistung: 500 kg/h Temperatur: 0-300 Grad. |

| Kakaobohnen-Schälmaschine |  | Leistung: 2,2 kW; Lüfterleistung: 2,2 kW Leistung: 1000 kg/h Größe: 2000x1100x2100 |

| Sortiermaschine für Kakaonibs |  | Größe: 4000x800x1300 (mm) Rollendurchmesser: 600 mm Leistung: 0,75 kW Leistung: 1000 kg/h |

Kommentar hinzufügen