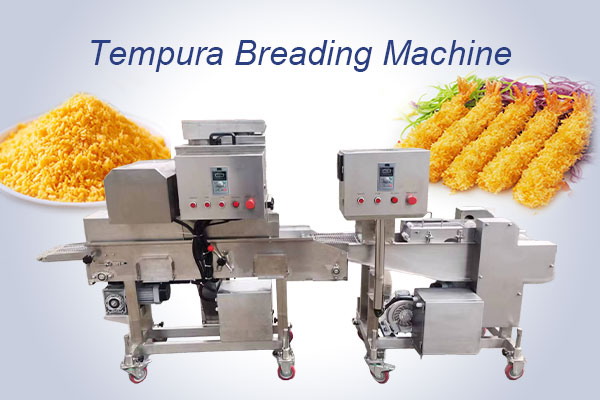

Die Krümelpaniermaschine, auch als Teigmaschine für Lebensmittel oder Paniermehlbeschichtungsmaschine bekannt, ist ein vielseitiges Gerät, das den Prozess der Paniermehlbeschichtung in der Lebensmittelproduktion rationalisieren soll. Mit seiner effizienten Struktur und seinen hohen Leistungsfähigkeiten revolutioniert diese Maschine die Art und Weise, wie Lebensmittel wie Chicken Nuggets und frittierte Snacks beschichtet und zubereitet werden. Taizy Machinery ist seit 10 Jahren in der Herstellung von Maschinen für die Lebensmittelverarbeitung tätig und hat automatische Teig- und Paniermaschinen in viele andere Länder exportiert, darunter Amerika, Kanada, Brasilien, Chile, Australien, Malaysia, Thailand, Frankreich, Italien, Großbritannien und den Jemen , Südafrika, Kenia, Kongo usw.

Das Panieren von Lebensmitteln verbessert Textur, Aussehen und Mundgefühl, während es den Geschmack verstärkt und die Feuchtigkeit bewahrt. Dies macht Paniermehl zu einer der wichtigsten Zutaten, die häufig beim Kochen verwendet werden.

- Verleiht Lebensmitteln Textur und Mundgefühl: Die Semmelbrösel verleihen der Oberfläche des Lebensmittels eine besonders knusprige Textur und verleihen ihm mehr Kaubarkeit und Textur. Dies gilt insbesondere für frittierte Lebensmittel wie Garnelen, Chicken Nuggets und Fisch, bei denen die Semmelbrösel für eine goldene, knusprige Außenschicht sorgen.

- Für ein attraktives Erscheinungsbild: Die Semmelbrösel bedecken die Oberfläche des Lebensmittels und bilden eine gleichmäßige Schicht, wodurch das Lebensmittel attraktiver aussieht. Dies ist für den kommerziellen Lebensmittelverkauf wichtig, da Lebensmittel, die gut aussehen, tendenziell die Aufmerksamkeit des Verbrauchers leichter auf sich ziehen.

- Hält Lebensmittel feucht: Semmelbrösel speichern die Feuchtigkeit beim Kochen und verhindern ein übermäßiges Austrocknen der Lebensmittel. Dies ist besonders bei Backwaren nützlich, da die Lebensmittel im Inneren feucht bleiben und sichergestellt wird, dass Textur und Geschmack erhalten bleiben.

- Verbessert den Geschmack von Lebensmitteln: Semmelbrösel selbst haben ein bestimmtes Aroma und einen bestimmten Geschmack, der Lebensmitteln zusätzlichen Geschmack verleihen kann. Darüber hinaus können Semmelbrösel während des Garvorgangs andere Gewürze und Gewürze aufnehmen und so den Speisen einen intensiveren Geschmack verleihen.

Aufbau und Bestandteile der Krümelpaniermaschine

Die Krümelpaniermaschine besteht aus mehreren wesentlichen Komponenten, die zu ihrer effektiven Leistung beitragen. Dazu gehören:

- Trichter: Ein großer Behälter, in den Semmelbrösel oder Teigmischung geladen werden.

- Fördersystem: Transportiert das Lebensmittelprodukt durch den Beschichtungsprozess.

- Beschichtungstrommeln: Rotierende Trommeln, die Semmelbrösel oder Teig gleichmäßig auf dem Lebensmittelprodukt verteilen.

- Luftgebläse: Entfernt überschüssige Beschichtung und sorgt für eine gleichmäßige Beschichtungsschicht.

- Bedienfeld: Ermöglicht dem Bediener die Anpassung von Einstellungen und die Überwachung des Maschinenbetriebs.

Die Semmelbrösel-Beschichtungsmaschine der Taizy-Fabrik wird normalerweise in Verbindung mit einer automatischen Teigmaschine verwendet. Im Betrieb werden die beiden Maschinen zu einer Einheit zusammengefasst. Die Lebensmittel werden zunächst in der Teigmaschine paniert und anschließend in der Paniermaschine zusammen mit dem Förderband gleichmäßig mit Semmelbröseln bedeckt. Dieses kombinierte Krümelpaniersystem wird häufig in großen und mittleren Lebensmittelverarbeitungsbetrieben eingesetzt.

Die Krümelpaniermaschine zeichnet sich durch ihre Fähigkeit aus, Lebensmittelprodukte effizient mit Semmelbröseln oder Teig zu überziehen. Der Arbeitsprozess umfasst typischerweise die folgenden Schritte:

- Beladen: Semmelbrösel oder Teigmischung werden in den Trichter geladen.

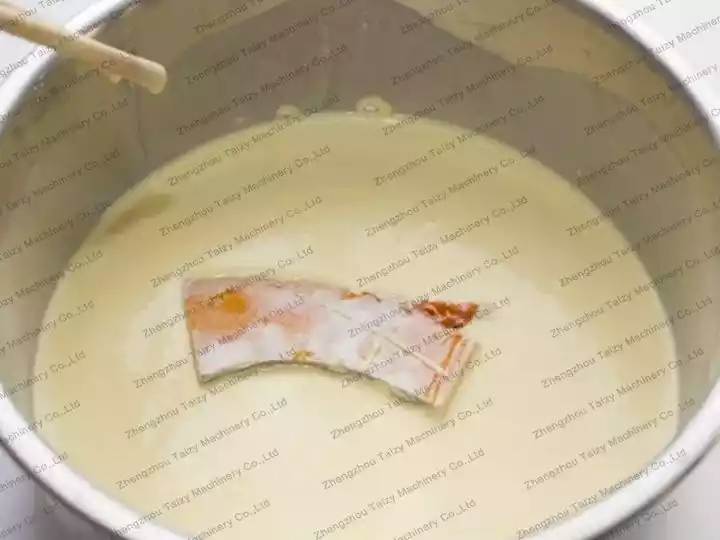

- Fördern: Das Lebensmittelprodukt wird auf das Förderband gelegt und durch die Maschine bewegt.

- Beschichten: Während das Lebensmittelprodukt durch die rotierenden Beschichtungstrommeln läuft, haften Semmelbrösel oder Teig an der Oberfläche und sorgen so für eine gleichmäßige Beschichtung.

- Entfernung überschüssiger Beschichtung: Das Luftgebläse entfernt überschüssige Beschichtung und sorgt so für ein gleichmäßiges und optisch ansprechendes Endprodukt.

- Sammlung: Beschichtete Lebensmittel werden gesammelt und können der nächsten Produktionsstufe zugeführt werden.

Anwendungen und Vorteile der Verwendung einer Krümelpaniermaschine

Die Krümelpanademaschine findet in verschiedenen Lebensmittelindustrien weitreichende Verwendung, insbesondere bei der Herstellung von Chicken Nuggets, frittierten Lebensmitteln und beschichteten Snacks. Zu seinen Vorteilen gehören:

- Erhöhte Effizienz: Die Maschine automatisiert den Beschichtungsprozess und erhöht so die Produktionsgeschwindigkeit und den Output deutlich.

- Gleichmäßige Beschichtung: Die rotierenden Trommeln sorgen für eine gleichmäßige Verteilung der Semmelbrösel oder des Teigs, was zu einer gleichmäßigen Beschichtungsdicke führt.

- Verbesserte Produktqualität: Der präzise Beschichtungsprozess stellt sicher, dass jedes Lebensmittelprodukt eine gleichmäßige und attraktive Beschichtung erhält, was die optische Attraktivität und die Kundenzufriedenheit steigert.

- Kostenreduzierung: Durch die Automatisierung des Beschichtungsprozesses senkt die Maschine die Arbeitskosten und minimiert den Beschichtungsabfall, was zu Gesamtkosteneinsparungen beiträgt.

- Hygienisches Design: Die Maschine besteht aus Materialien in Lebensmittelqualität, die eine einfache Reinigung und Wartung ermöglichen und so die Lebensmittelsicherheit und die Einhaltung von Vorschriften gewährleisten.

Die Paniermehlbeschichtungsmaschine wird häufig bei der Zubereitung von gebratenem Hähnchen, Fischfilet, gebratenen Garnelen, gebratenem Gemüse, frittierten Käsebällchen und anderen Lebensmitteln verwendet. Es kann eine gleichmäßige Abdeckung mit Semmelbröseln gewährleisten, um das Essen beim Kochen knuspriger und köstlicher zu machen.

Darüber hinaus können mit der Krümelpaniermaschine auch vegetarische oder frittierte Lebensmittelersatzprodukte hergestellt werden, was eine Vielzahl von Möglichkeiten für Vegetarier oder Menschen mit besonderen Ernährungsbedürfnissen bietet. Es eignet sich für alle Arten von Lebensmittelunternehmen wie Fast-Food-Ketten, Restaurants, Lebensmittelverarbeitungsbetriebe usw., insbesondere für solche, die frittierte Lebensmittel in großen Mengen herstellen müssen.

Parameter der Teig- und Krümelpaniermaschine

Parameter der Teig-Maschine

| Modell | TZ-1300 |

| Leistung | 0,6 kW |

| Gürtelbreite | 200mm |

| Material | Edelstahl 304 |

| Größe | 1300*400*1000mm |

Parameter der Krusten-Brotmaschine

| Modell | TZ-1600 |

| Leistung | 0,92 kW |

| Gürtelbreite | 200mm |

| Material | Edelstahl 304 |

| Größe | 1600*550*1500mm |

Kommentar hinzufügen