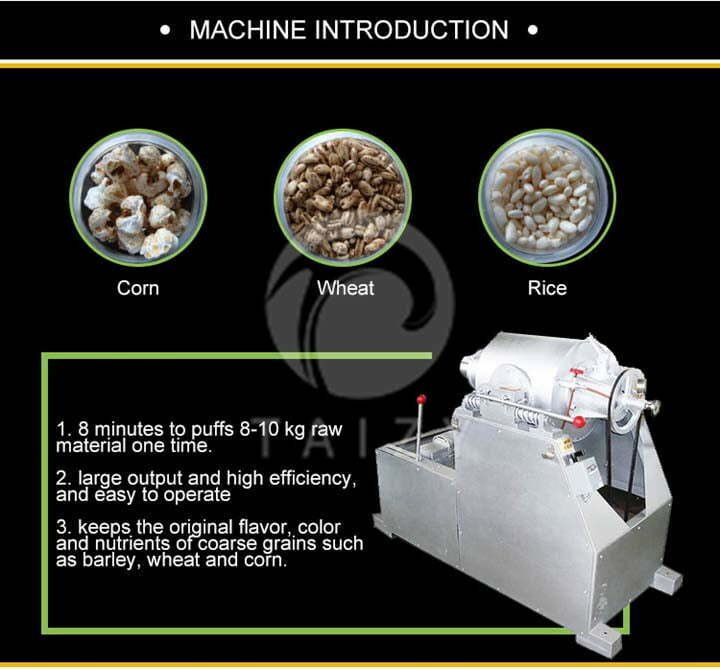

Die Luftaufblasmaschine dient zur Herstellung von Puff-Lebensmitteln. Sie verwendet Gasheizung, und die Rohmaterialien können Sojabohnen, Mais, Reis, Weizen und alle Arten von Nüssen sein. Sie zeichnet sich durch hohen Durchsatz, geringen Energieverbrauch und hohe Arbeitseffizienz aus. Darüber hinaus führen wir vor der Auslieferung der Maschine strenge Tests durch.

Betriebsvideo einer Maschine zum Puffen von Getreide mit Luftstrom

Technische Parameter der Reisweizen-Füllmaschine

| Stromversorgung | einphasig 220 V |

| Leistungskapazität | 0,75 kW |

| Kapazität | 50-60kg/h |

| Leergewicht | 450kg |

| Größe | 1650×800×1350mm |

Wie bedient man eine Luftblasmaschine?

1. Vor der Arbeit sollte der Bediener das Antriebsteil schmieren und prüfen, ob das Betriebsteil locker ist oder nicht.

2. Beim ersten Puffen sollte die Popcorn-Füllmaschine auf 120 °C erhitzt und dann heruntergefahren werden. Der Rohstoff kann mit 50g essbarem Talk vermischt werden. Hinweis: Die Anforderungen an das Rohmaterial: keine Rückstände und der Feuchtigkeitsgehalt beträgt weniger als 15%

3. Ladevorgang: Laden → Deckel → Deckel festziehen →Erhitzen

4. Laden: Lösen Sie den Griff nach außen, drehen Sie das Handrad, um die Flasche um 45° nach oben zu drehen, gießen Sie das Material ein, schließen Sie den Deckel, stellen Sie das Handrad zurück und verriegeln Sie die Flasche zum Erhitzen.

5. Schalten Sie während des Heizvorgangs alle 3 bis 4 Minuten den Trommelschalter ein, um die Richtung zu ändern und das Material gleichmäßiger zu erhitzen.

6. Je nach Rohstoffunterschied wählen Sie eine Feuerlöschanlage mit entsprechendem Druck (normalerweise 8 kg Reis, 10 kg Mais). Um den besten Puffeffekt zu erzielen, ist außerdem die Brennzeit unterschiedlich.

Wie wird das aufgeblähte Futter entsorgt?

1. Ziehen Sie die Pufferhalterung unter den Topf.

2. Schließen und verriegeln Sie das Gas, um das Feuer auszuschalten.

3. Der Bediener muss auf der rechten Seite der Maschine stehen und den Griff mit einem Spezialschlüssel bewegen.

4. Entfernen Sie nach dem Betrieb überschüssige Rückstände aus dem Topf.

Hinweis: Entladeverfahren sind sehr wichtig und der Bediener sollte darauf achten.

Die Vorsichtsmaßnahmen der Luftblasmaschine

- Lässt sich der Deckel nicht festziehen, muss die Dichtung ausgetauscht werden.

- Dort Luftstoßmaschine muss mit einem Bezugserdungsleiter ausgestattet sein, um Kriechströme zu verhindern.

- Wenn ein Leck in der Flüssiggasleitung festgestellt wird, muss die Maschine angehalten und das Hauptventil nach der Inspektion geschlossen werden.

- Wenn die Weizenfüllmaschine in Betrieb ist, dürfen Menschen nicht davor stehen.

- Während des Betriebs gibt es viel Lärm und es ist eine Schalldämmung erforderlich.

- Im Normalbetrieb muss das Drehlager einmalig geschmiert werden (hitzebeständig 500°C).

Methode: Drücken Sie mit einer Ölpistole etwas Fett in den Einfüllbecher und geben Sie eine kleine Menge Schmiermittel auf jedes rotierende Teil

Detaillierte Informationen zu den einzelnen Ersatzteilen.

| Teilebeschreibung | ||

| 1 | Handrad | zum Be- und Entladen verwenden |

| 2 | Thermometer | Zeigt die Temperatur des Tanks an |

| 3 | Manometer | Zeigt den Druck des Tanks an |

| 4 | Fett | Hochtemperaturfett einfüllen |

| 5 | LPG-Ventil | Öffnen und schließen Sie das LPG |

| 6 | Drehbarer Verriegelungsgriff | Vorwärts ist die Verriegelung. Zurück ist das Öffnen des Schlosses |

| 7 | Drehbarer Verriegelungsgriff | Ziehen Sie es heraus, öffnen Sie das Schloss und geben Sie das Schloss danach automatisch frei |

| 8 | Drehen der Anschlagplatte | Verriegelung des externen Tanks |

| 9 | Externer Tank | Unterstützung im Tank |

| 10 | Im Tank | Installationsmaterial |

| 11 | Dichtung | Dichtwirkung |

| 12 | Abdeckung | Beim Puffen muss der Bezug zusammengedrückt werden |

| 13 | Stift | Öffnen und schließen Sie den Deckel |

| 14 | Stiftgriff | Verwickeln Sie es mit dem Nachbrennerstab und sprengen Sie es dann |

| 15 | Rücklaufsperre | zur Unterstützung nutzen |

| 16 | Schrauben | zum Verriegeln verwenden |

| 17 | Bildpuffer | Bevor Sie den Deckel öffnen, schieben Sie ihn nach innen |

| 18 | Rahmenpuffergriff | Wird zum Verschieben des Bildpuffers verwendet |

| 19 | Heizbereich | zum Heizen verwenden |

| 20 | Motor | kann den Tank drehen lassen |

| 21 | Gürtel | Transport |

| 22 | Switchback Shun | kann machen, dass der Tank gedreht und gegengedreht wird, |

| 23 | Stabnachbrenner | Vor dem Erhitzen den Deckel damit verriegeln. 2. Nach dem Erhitzen den Deckel damit öffnen |

Vorteil der Müsli-Puffmaschine

- Pufffutter kann direkt verzehrt werden und schmeckt hervorragend.

- Die Luftstoßmaschine kann mit verschiedenen Rohstoffen wie Reis, Weizen, Mais und Nüssen usw. umgehen.

- Die Puffzeit ist kurz, was viel Zeit spart.

- Die Müsli-Puffmaschine ist aus Edelstahl gefertigt und entspricht den nationalen Hygienestandards, die weithin für die gelten Produktionslinie für Erdnussbonbons.

- Das fertig gepuffte Lebensmittel kann den ursprünglichen Nährstoff behalten, was für den Menschen gesund ist.

FAQ

1. Wie hoch ist die Temperatur des Topfes vor der Verarbeitung?

Es sollte auf 120 ℃ vorgeheizt werden.

2.Kann ich dem Rohmaterial vor dem Betrieb etwas Würze hinzufügen?

Ja, natürlich können Sie es je nach Bedarf tun.

3.Was ist der Rohstoff?

Dies können Sojabohnen, Mais, Reis, Weizen und alle Arten von Nüssen sein.

Kommentar hinzufügen