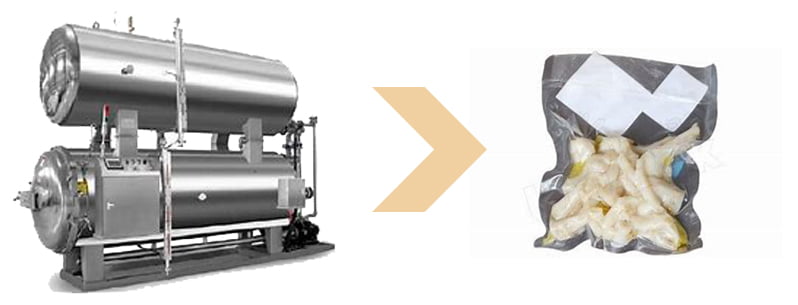

Die industrielle Lebensmittelsterilisationsmaschine wird in der Lebensmittelindustrie zum Sterilisieren verarbeiteter Lebensmittel eingesetzt. Nach der Sterilisation mit dem Lebensmittelsterilisator kann die Stabilität der Lebensmittel gewährleistet und die Haltbarkeit der Lebensmittel verlängert werden. Je nach Sterilisationsmethode verfügt die Lebensmittelsterilisationsmaschine über verschiedene Sterilisationsmaschinen wie Autoklav-Sterilisationsmaschine, Wasserbad-Sterilisationsmaschine, Pasteurisationsmaschine und so weiter. Industrielle Lebensmittelsterilisationsmaschinen werden häufig zur Sterilisation von Retortenbeuteln und zum Einmachen von Lebensmitteln eingesetzt.

Arten von Lebensmittelsterilisatormaschinen

Je nach Sterilisationsmethode umfassen Lebensmittelsterilisationsmaschinen hauptsächlich Autoklavensterilisationsmaschinen, Wasserbadsterilisationsmaschinen, Pasteurisationsmaschinen und andere Maschinen. Sie eignen sich zur Sterilisation von Konserven und verpackten Lebensmitteln.

Hochdruck-Autoklav-Sterilisationsmaschine

Der Hochtemperatur-Autoklav-Sterilisator wird häufig für die Sterilisation von konservierten oder verpackten Lebensmitteln wie Fleisch, Bohnen, Pilzen und Fisch eingesetzt. Entsprechend den verschiedenen Sterilisationsmethoden kann die Maschine verschiedene Sterilisationsmethoden wie Dampftyp, Wasserbadtyp, Sprühtyp usw. auswählen.

Die Eigenschaften der Autoklav-Sterilisationsmaschine

- Gleichmäßige Wärmeverteilung, kein toter Winkel, das zirkulierende Wasser im Sterilisationstank fließt gleichmäßig, wobei die Fließrichtung ständig nach oben, unten, links und rechts wechselt, wodurch sichergestellt wird, dass jeder Punkt der Wärmeverteilung im Inneren des Behälters ab der Heizperiode gleichmäßig ist. Wärmekonservierung bis Kühlung.

- Die Hochtemperatur-Kurzzeitsterilisation wird durch die Verwendung der Doppelkessel-Heißwasserzirkulation als Sterilisationsmittel erreicht. Das Wasser im Warmwassertank wird zunächst auf die für die Sterilisation erforderliche Temperatur erhitzt (außer mehrstufige Sterilisation), wodurch die Sterilisationszeit verkürzt und die Arbeitseffizienz verbessert wird.

- Sparen Sie Energie. Das im Sterilisationsprozess im Sterilisationsgefäß verwendete Arbeitsmedium Wasser kann recycelt werden, um Energie zu sparen, die Zeit zu verkürzen, Personalaufwand und Abfall zu reduzieren und so die Produktionskosten zu senken.

- Automatisches Kontrollsystem. Der gesamte Sterilisationsprozess kann vom Computer gesteuert werden, sodass der Vorgang automatisch abgeschlossen werden kann.

- Der bakterizide Wasserkocher verfügt über ein Temperatursimulationskontrollsystem, das vor dem Start einen mehrstufigen Heizmechanismus einstellen kann.

Parameter der Lebensmittelsterilisatormaschine für Retortenbeutel

| Durchmesser (mm) | Länge (mm) | Volumen (m³) | Dicke

(mm) |

Wasserpumpe | ||

| Typ | Nummer | |||||

| Sterilisatortopf | Thermokessel | |||||

| φ500 | 800 | 0.20 | 4 | 4 | DN20 | 2 |

| φ600 | 1000 | 0.35 | 4 | 4 | DN32 | 2 |

| φ700 | 1200 | 0.57 | 4 | 4 | DN40 | 2 |

| 1500 | 0.69 | 4 | 4 | DN40 | 2 | |

| 1800 | 0.80 | 4 | 4 | DN40 | 2 | |

| φ900 | 1800 | 1.37 | 4 | 4 | DN65 | 2 |

| φ1000 | 2200 | 2.03 | 4 | 4 | DN65 | 2 |

| 2400 | 2.18 | 4 | 4 | DN80 | 2 | |

| 2600 | 2.34 | 4 | 4 | DN80 | 2 | |

| 3000 | 2.66 | 4 | 4 | DN80 | 2 | |

| φ1200 | 2700 | 3.56 | 5 | 5 | DN80 | 2 |

| 3000 | 3.90 | 5 | 5 | DN80 | 2 | |

| 3600 | 4.58 | 5 | 5 | DN100 | 2 | |

| 4000 | 5.03 | 5 | 5 | DN100 | 2 | |

| φ1300 | 3000 | 4.62 | 5 | 5 | DN100 | 2 |

| 4000 | 5.95 | 5 | 5 | DN100 | 2 | |

| 5000 | 7.27 | 5 | 5 | DN100 | 2 | |

| φ1500 | 4000 | 8.04 | 5 | 5 | DN125 | 2 |

| 5000 | 9.80 | 5 | 5 | DN125 | 2 | |

| 6000 | 11.58 | 5 | 5 | DN125 | 2 | |

| Auslegungsdruck | 0,35 MPa |

| Maximaler Druck | 0,30 MPa |

| Material | SUS304 |

| Auslegungstemperatur | 147℃ |

Wasserbad-Sterilisator

Der Wasserbadsterilisator wird häufig in Konservenfabriken eingesetzt. Diese Maschine ist die ideale Ausrüstung zum Pasteurisieren von Fruchtmark in Dosen. Die Hochtemperatur- und Hochdruck-Wasserbad-Sterilisationsmaschine kann eine kontinuierliche Sterilisation erreichen und die Temperatur kann selbst eingestellt werden. Beim Sterilisieren kann der Flaschenkörper des Lebensmittels in wärmeleitendem Wasser eingeweicht werden. Daher macht die Maschine die Sterilisation gründlicher.

Maschine zum Pasteurisieren von Lebensmitteln

Pasteurisatoren haben ein sehr breites Anwendungsspektrum. Es wird häufig zum Sterilisieren von Milchprodukten, Sojaprodukten, Konserven, abgepackten Lebensmitteln und anderen Lebensmitteln verwendet. Der Pasteur kann auch eine Sterilisationslinie mit Geräten wie einem Kühler, einem Vibrationsabtropfgerät, einer lufttrocknenden Entwässerungsmaschine und einem Förderband bilden. Die Montagelinie kann entsprechend unterschiedlicher Produkte, unterschiedlicher Leistung und unterschiedlicher Prozessanforderungen entworfen und produziert werden, um den Bedürfnissen der Kunden auf verschiedenen Ebenen gerecht zu werden.

Kommentar hinzufügen