The commercial vegetable dicing machine is suitable for processing a variety of root vegetables into cube and cuboid shapes. Such as tomatoes, potatoes, onions, cucumbers, carrots, and other raw materials. The dicing machine adopts composite props, forming at one time, the shape of the cut pieces is uniform and the output is large. It has been exported to Thailand, Bulgaria, Panama, Japan, and other regions.

Commercial vegetable dicing machine usage method

Operation before use

- Fix the feeding hopper to the feeding part of the shell with screws

- Check if there is any foreign matter in the feed inlet. If there is, please use it after cleaning to reduce damage to the blade

- Connect the power supply, press the “on” button, and check whether the steering is correct

Operation and use of tomato dicing machine

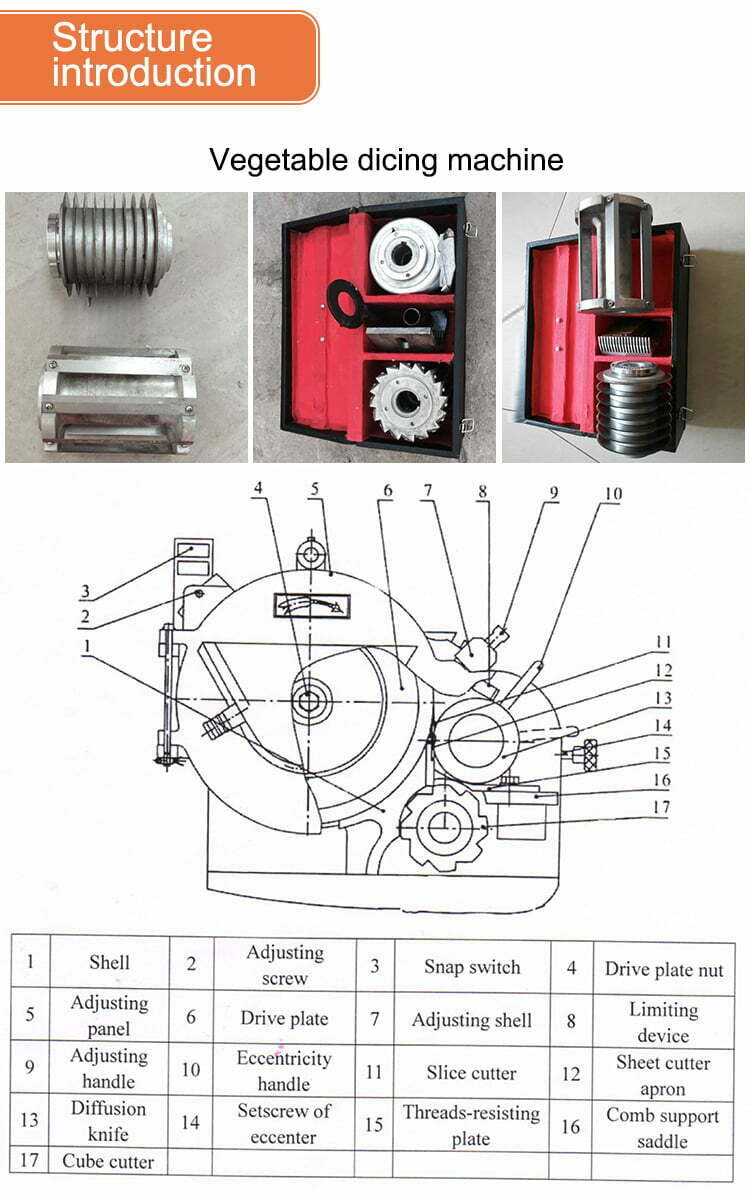

Wash the tomatoes to remove the sediment to reduce damage to the blade. And the maximum diameter of the tomato should not exceed 80mm. If it exceeds, you should first cut it into small pieces before putting it into the feed inlet. After the tomatoes are put into the feeding port, under the action of the dial, the vertical knife cuts to the required thickness, and then the disc shredder cuts into strips. Finally, a cross-cutting knife cuts the tomatoes into cubes.

How to adjust the size of the tomato dicing machine

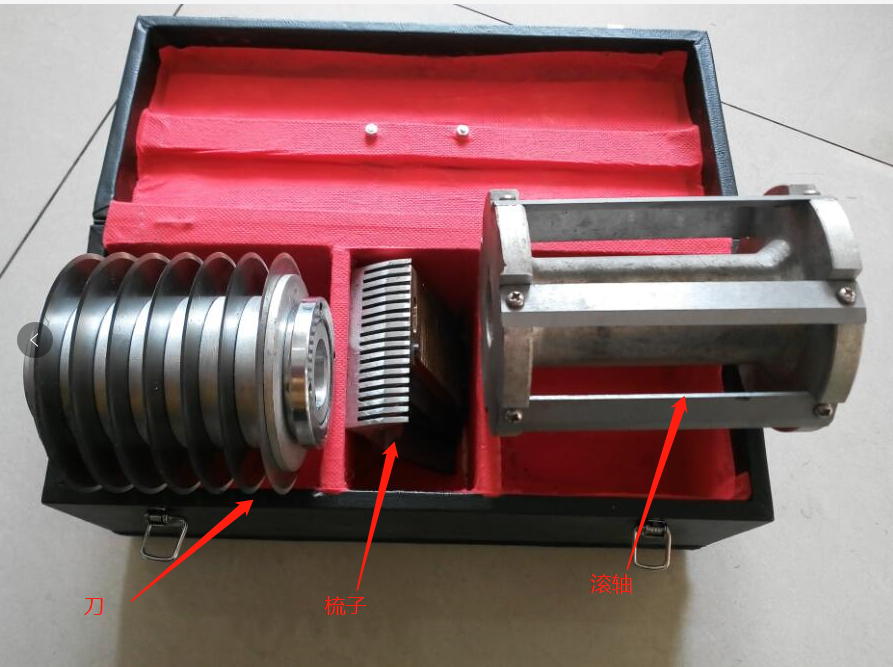

You can adjust the dicing size by adjusting the thickness of the slice and changing the distance between the cross-cut and vertical cutter of the disc. Because the machine structure of the vegetable dicer machine is compact, we do not recommend customers to adjust the size between the blades to prevent the blade moving position and uneven dicing. We have a variety of dicing size knives to choose from, so you can purchase a few more sizes for replacement.

How to maintain a commercial vegetable dicer machine

- Every time you use the vegetable dicing machine, you should clean it, especially where the material touches

- After each use, check whether the cutting tool is damaged or worn. And you should disassemble the disc tool assembly once a week for proper cleaning. Before installation, apply food oil on the cutting shaft and the cutting shaft to ensure easy disassembly.

- Oil the gears and chains once every two weeks to ensure lubrication

Add Comment