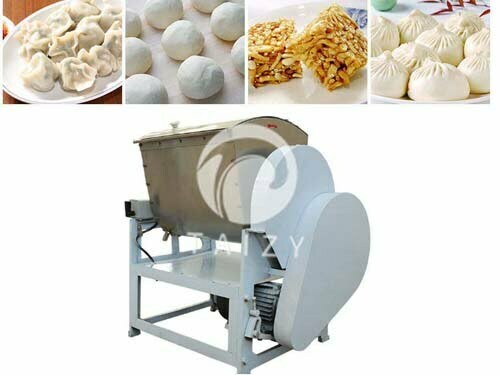

آٹا مکسر بہت سی فوڈ پروسیسنگ کے لیے ایک ضروری مشین ہے۔ مثال کے طور پر، کیریمل پروڈکشن لائن، مونگ پھلی کی کینڈی پروڈکشن لائن وغیرہ کا علاج کرتا ہے۔ ایک ہی وقت میں، یہ ایک کثیر مقصدی مشین بھی ہے۔ مشین کو لے جانے کے لئے بہت آسان ہے، صرف دو سوئچ مشین کے آپریشن کو کنٹرول کرتے ہیں، اور ایک ہنگامی سٹاپ بٹن کو ہنگامی صورتحال میں چلایا جا سکتا ہے. یہ بنیادی طور پر ایک چاقو، ایک بیرل، ایک موٹر، اور ایک گیئر باکس پر مشتمل ہے۔

کا تعارف آٹا مکسر

ہمارے کارخانے کے ذریعہ تیار کردہ کم شور سیریز ڈو مکسنگ مشین کو رنگ کی قسم اور چھری کی قسم میں تقسیم کیا گیا ہے۔ اس کی خصوصیات میں خوبصورت شکل، مستحکم کارکردگی، مضبوط طاقت، اور دیرپا ہونا شامل ہے۔ یہ مشین آریٹر کی گردش کا استعمال کرتی ہے تاکہ آٹے اور پانی کو ہاپر میں چھوٹے ذرات میں تبدیل کیا جا سکے۔ پھر چھوٹے ذرات آپس میں چپک کر ایک آٹے کا بلاک بناتے ہیں۔ جیسے ہی آریٹر آٹے کو فولڈ، اسٹریچ، اور گوندھتا ہے، ہمیں آٹے کا بلاک ملتا ہے۔ یہ مشین ہوٹلوں، کینٹینز، اور دیگرپاستا پروسیسنگ یونٹس میں بڑے پیمانے پر استعمال ہوتی ہے۔

آٹا مکسر کی خصوصیات:

حیرت انگیز کم شور والا آٹا مکسر جس میں گیئر باکس ٹرانسمیشن، پللی، اور سپروکیٹ ڈرائیو ہے۔ اس میں مستحکم آپریشن، کم شور، کمپیکٹ ڈھانچہ، محفوظ آپریشن، اور آسان دیکھ بھال کے فوائد ہیں۔ fuselage اعلی معیار کے سٹیل سے بنا ہے. کیسنگ سٹینلیس سٹیل سے بنا ہے اور مضبوط اور خوبصورت ہے۔ فنل اعلیٰ معیار کے سٹینلیس سٹیل سے بنا ہے، جو سنکنرن سے مزاحم ہے اور کھانے کی حفاظت کے معیارات پر پورا اترتا ہے۔

انسٹالیشن اور ڈیبگنگ آٹا مکسر کا:

انسٹالیشن: انسٹالیشن: اسے فلیٹ ایریا میں نصب کیا جانا چاہیے، بغیر سنکنرن کے، کوئی آتش گیر اور دھماکہ خیز مواد گھر کے اندر نہ ہو۔ خشک رکھیں اور جب آٹا مکسر کام کر رہا ہو تو گرمی کو ختم کرنے کے لیے دیوار سے 15 سینٹی میٹر سے کم نہ ہو۔ پاور کنکشن منسلک کرنے سے پہلے مینوئل میں نشان زد تکنیکی پیرامیٹرز کو پڑھیں۔ بجلی کے رساو سے بچنے کے لیے دیوار کو گراؤنڈ کیا جانا چاہیے۔

ڈیبگنگ: براہ کرم آٹا مکسر سے پیکج کو ہٹانے کے بعد تفصیل سے چیک کریں۔ لمبی دوری کی نقل و حمل کی وجہ سے، کچھ فاسٹنرز ڈھیلے ہو سکتے ہیں۔ لہذا، حادثات سے بچنے کے لیے استعمال کرنے سے پہلے آٹا مکسر کا اچھی طرح معائنہ کیا جانا چاہیے۔ آدھے گھنٹے تک کام کرنے کی کوشش کریں، چیک کریں کہ اجزاء ڈھیلے ہیں یا نہیں، اور استعمال کرنے سے پہلے تصدیق کریں کہ سب کچھ نارمل ہے۔

آٹا مکسر کی درخواستیں:

ایک آٹا مکسر بڑے پیمانے پر کھانے کی پروسیسنگ میں استعمال کیا جاتا ہے، خاص طور پر کھانے کی پیداوار لائنوں میں. مثال کے طور پر، کیریمل ٹریٹ پروڈکشن لائن میں، پہلا مرحلہ یہ ہے کہ آٹے کو آٹے میں پروسس کریں۔ پھر آٹا کچھ قدموں کے بعد کیریمل ٹریٹ میں پروسیس کیا جاتا ہے۔ اس مشین کو مختلف قسم کے مواد کو ملانے کے لیے بھی استعمال کیا جا سکتا ہے، جیسے کہ ابلی ہوئی سٹفڈ بن فلنگ، ڈمپلنگ بھرنا وغیرہ۔

آٹا مکسر کے پیرامیٹرز:

| ماڈل | صلاحیت (کلوگرام) | اختلاط کا وقت (منٹ) | وولٹیج (v) | پاور (کلو واٹ) | وزن (کلوگرام) | سائز (ملی میٹر) |

| TZ-12.5 | 12.5 | 3-10 | 220/380 | 1.5 | 100 | 650*400*730 |

| TZ-25 | 25 | 3-10 | 220/380 | 1.5 | 128 | 685*480*910 |

| TZ-37.5 | 37.5 | 3-10 | 220/380 | 2.2 | 175 | 840*480*910 |

| TZ-50 | 50 | 3-10 | 220 | 2.2 | 230 | 1070*570*1050 |

| 380 | 2.575 | 275 | ||||

| TZ-75 | 75 | 3-10 | 380 | 3.75 | 475 | 1410*680*1250 |

| TZ-100 | 100 | 3-10 | 380 | 3.75 | 490 | 1520*680*1250 |

| TZ-150 | 150 | 3-10 | 380 | 6.25 | 700 | 1710*730*1400 |