ticari kahve kavurma makinesi Kabukları soyulmuş kahve çekirdeklerini pişirmek ve kahve çekirdeklerindeki fazla suyu uzaklaştırmak için kullanılır. Kavrulmuş kahve çekirdeklerinin aroması vardır ve toz haline getirildikten sonra tadı güzel olur. kahve çekirdeği kavurma makinesiTamburdaki pişirme sıcaklığını ayarlamak için pişirme haznesindeki sıcaklığı ve tüyerdeki sıcaklığı ölçen iki sensöre sahiptir. Ek olarak, küçük serili kahve kavurma makinesinde karıştırmayı, silindiri, soğutma fanını ve kahve çekirdeği kabuğunun toplanmasını kontrol eden dört motor bulunur.

Küçük kahve kavurma makinesi youtube videosu

Ticari kahve çekirdeği kavurma makinesinin teknik parametresi

| Modeli | Toplu kapasite | U*G*Y(mm) | Ana motor(w) | Egzoz gücü(w) | Soğutma gücü (w) | Karıştırma gücü(w) |

| SL-1 | 1 kg | 1400*450*980 | 60 | 25 | 80 | |

| SL-3 | 3 kg | 1300*550*1350 | 180 | 40 | 120 | 90 |

| SL-6 | 5-6 kg | 1550*750*1750 | 370 | 90 | 330 | 180 |

Kahve çekirdeği kavurma makinesi kapasitesi nedir?

Farklı müşterilerin ihtiyaçlarına göre çeşitli model ve çıkışlarda ticari ve endüstriyel kahve kavurma makineleri sunuyoruz. Küçük kahve kavurma makinelerinin çıktısı parti başına 1kg, 2kg, 3kg, 6kg, 10kg'dır. Büyük endüstrilerdeki kahve kavurma makinelerinin üretimi esas olarak parti başına 15kg, 30kg, 60kg'dır.

Kahve çekirdeklerinin kabukları nasıl soyulur?

Kuru kahve çekirdekleri soyma makinesi

Kahve çekirdekleri ihraç edilmeden önce kahve çekirdeklerinin iç kabuğu öğütülerek çıkarılır. Aslında ıslak işleme sırasında kahve çekirdeklerinin iç kabuğunu çıkarmak daha zordur. Kahve çekirdeklerinin kabukları soyulurken orta derecede nem içeriğine sahip olması gerekir, aksi takdirde kırılabilirler.

Kahve çekirdekleri soyma makinesi

Kahve soyma makinesi, kahve çekirdeklerinin kabuğunu çıkarmak ve ardından temiz kahve çekirdekleri elde etmektir. Soyulma oranı 95%'ye ulaşabilir, daha da önemlisi işlenmiş kahve çekirdekleri bozulmadan kalabilir ve kahve çekirdekleri ve kabukları farklı çıkışlardan boşaltılabilir. Farklı türde kahve çekirdeği soyma makinelerimiz var ve aşağıdaki bunlardan biri.

| Gerilim | 220v |

| Güç | 1,5 kW |

| Kapasite | 100-200kg / saat |

| Ağırlık | 103 kilo |

| Boyut | 775*440*890mm |

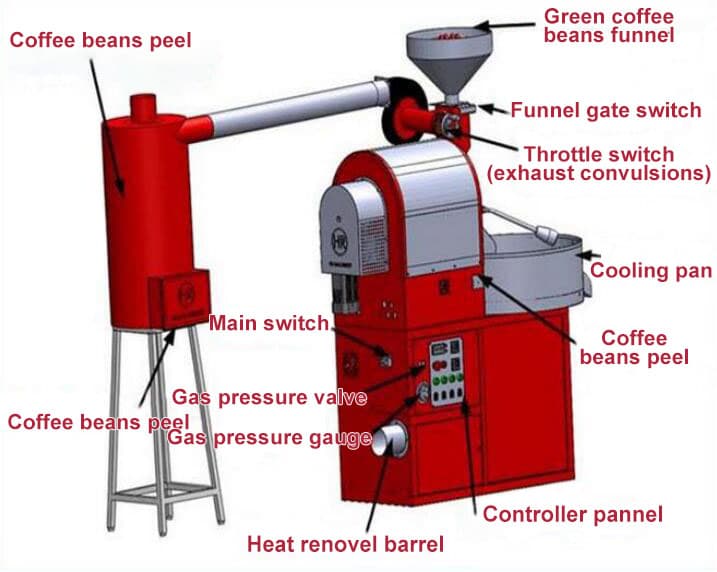

Kahve kavurma makinesinin yapısı nedir?

Kahve çekirdekleri kavurma makinesi makul bir yapıya sahiptir. Temel olarak yeşil kahve çekirdekleri hunisi, kahve çekirdekleri soyma varili, huni kapısı anahtarı, gaz kelebeği anahtarı (egzoz konvülsiyonları), soğutma tavası, ana anahtar toplayıcı, Gümüş deri çıkışı, Gaz basınç valfi, Gaz basınç göstergesi, ısı giderme varili, kontrol paneli.

Kahve çekirdekleri kavurma makinesi nasıl çalıştırılır?

- Şunu yükleyin: kahve çekirdekleri kavurma ve güç bağlantısının doğru olup olmadığını kontrol edin ve gazı açın.

- Kahve yeşil çekirdeklerini hazırlayın ve kahve çekirdeği kavurma makinesine dökün.

- Gücü açın, sıcaklık kontrol cihazı ve zamanlayıcı göstergesi yanar, pişirme düğmesine tıklayın (çalışma durumu için ışık açıktır) ve pişirme haznesi tamburu eşit hızda dönmeye başlar. Soğutma fanı ve soğutma karıştırıcısı kapalı (gösterge ışığı kapalı).

- Gazı açın, hava basıncını 0,5-1 Pa'ya ayarlayın, ardından tamburu ateşleyin ve önceden ısıtın.

- Tamburun sıcaklığı 160-170 santigrat dereceye ulaştığında hazne anahtarını açın ve kahve çekirdekleri pişirme odasına girer. Farklı pişirme aşamalarının pişirme gereksinimlerini karşılamak için üst fanın hava hacmini ayarlayın. Egzoz ayar butonunu kullanarak duman tahliyesini ve kahve çekirdeği kabuğunun toplanmasını farklı aşamalarda ayarlayın.

- 5 dakika pişirdikten sonra, kahve çekirdeklerinin rengini yüksek sıcaklık gözlem penceresinden kontrol etmeli veya kahve çekirdeklerini pişirme odasından çıkarmak için numune alma kaşığını kullanmalısınız. Aynı zamanda duman tahliyesini ve kahve çekirdeklerinin soyulmasını kontrol etmek için üst fan akış düğmesini egzoz akışına göre ayarlayın. Pişirme haznesinin sıcaklığı üst fanın hava hacmi ile kontrol edilebilmektedir.

Operasyon sırasında nelere dikkat edilmelidir?

- Çok fazla duman gördüğünüzde, en iyi pişirme koşuluna hakim olmak ve en iyi pişirme etkisini elde etmek amacıyla kahve çekirdeklerinin rengini tespit etmek için numune alma kaşığını kullanın.

- Pişirme gereksinimleri karşıladığında, önce soğutma karıştırma düğmesine ve soğutma fanı düğmesine basın, ardından pişirme odası anahtarını açın. Kavrulmuş kahve çekirdeklerini soğutmak için güçlü hava soğutmalı karıştırma plakasına bırakın. 2-3 dakika soğuduktan sonra boşaltma anahtarını açın. (Sürekli pişirme gerekiyorsa, sürekli üretim gerçekleştirmek için kahve çekirdeklerini pişirme haznesine yerleştirmeye devam edebilirsiniz).

- Pişirdikten sonra, fırını kapatmadan önce pişirme odası sıcaklığının 70 santigrat derecenin altına düşmesini bekleyin. kahve kavurma makine.

- Kahve çekirdeklerinin kabuk toplama kutusu ve toz toplama kovası tıkanmayacak şekilde pişirme sayısına göre temizlenmelidir.

- Çalışma sırasında pişirme etkisini sağlamak için egzoz ve soğutma hava kanallarının düzgün akışını sağlamalısınız.

Ticari kahve kavurma makinesinin özellikleri nelerdir?

- Farklı model ve kapasitelerde kahve kavurma makinemiz mevcut olup, ihtiyaçlarınıza göre özelleştirilebilmektedir.

- Taizy kahve kavurma makinesi tarafından işlenen kahve çekirdekleri harika bir aroma ve güzel bir renge sahiptir, öğütüldükten sonra toz haline getirilir ve daha sonra kahve haline getirilir, size harika hisler verecektir.

- Bu kahve çekirdekleri kavurma makinesi, kahve dükkanı ve kahve işleme endüstrilerinde yaygın olarak uygulanır ve yüksek faydalar sağlayabilir.

- Pişirme etkisi çok iyidir ve kapasitesi yüksektir.

- Otomatik bir kontrol sistemine sahiptir, bu nedenle tüm işlem uygundur.