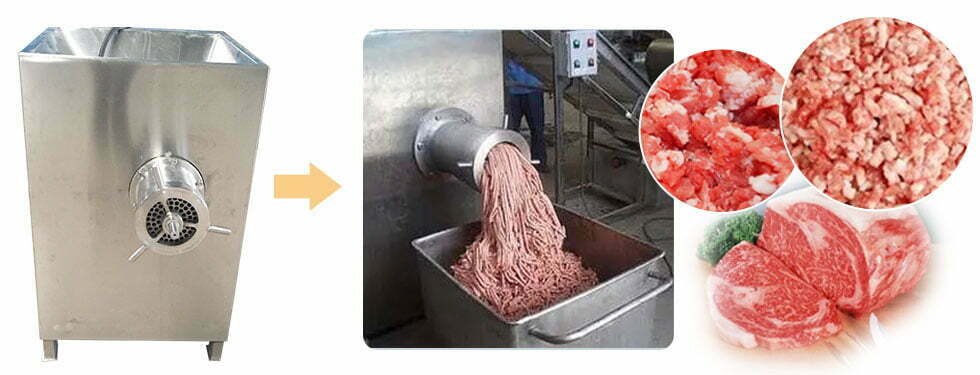

Endüstriyel dondurulmuş kıyma makinesi, et işlemede vazgeçilmez yardımcı ekipmanlardan biridir. Et üretim endüstrisinde yüksek çok yönlülüğe ve geniş uygulamaya sahiptir. Ekipman, besleme kutusundaki çiğ eti, vida çubuğunun baskısıyla ön kesim bölümüne doğru iter. Döner ekstrüzyon boyunca delikli plakanın ve raybanın birbirine göre çalışmasını sağlar. Bu nedenle çiğ eti parçacık şeklinde keserek et dolgusunun düzgün olmasını sağlar. Farklı boyutlardaki et dolum granüllerindeki üretim gereksinimlerini karşılamak için farklı delikli plaka kombinasyonları kullanılabilir.

Ticari dondurulmuş kıyma makinesi uygulaması

Ticari dondurulmuş kıyma makinesi, restoranlarda, işletmelerin yemekhanelerinde ve kıyma yapmak için et kavurma ve kurutulmuş pastırma fabrikalarında yaygın olarak kullanılmaktadır. Endüstriyel dondurulmuş kıyma makinesi, her türlü dondurulmuş et, taze et, kemikli tavuk, kemikli ördek, koyun eti, derili tavuk ve sığır eti, balık vb. işlemek için geçerlidir.

Endüstriyel kıyma makinesi sınıflandırması

Et işleme derecesine göre taze kıyma makinesi ve dondurulmuş kıyma makinesi içerir. Gıda işleme endüstrisinde tek kademeli kıyma makineleri daha sık kullanılmaktadır. Farklı delikli plaka boyutlarını değiştirerek ayarlanabilir kalınlık amacına ulaşabilir. Aynı zamanda hammadde sıcaklığının yükselmesinin et kalitesini olumsuz etkilemesini de önler.

Kıyma makinesinin çalışma prensibi

Kıyma makinesi, et işlemede en yaygın kullanılan makinedir. Esas olarak öğütme ve kıyma etkisine paslanmaz çelik ızgara plakası ve çapraz kesici bıçağın etkileşimi altında ulaşır. Bu işlem sırasında etler doğranacak, kıyılacak ve daha sonra dolgu yapımı için et şeritleri haline getirilecek.

Kıyma makinesi esas olarak besleme ünitesi, et kıyma haznesi, kesme ünitesi ve aktarma ünitelerinden oluşur.

İşleme sırasında, dönen kesme bıçağı ve delikli plaka üzerindeki delikli bıçağın oluşturduğu kesme etkisi altında çiğ et kıyılır ve öğütülür. Vidanın etkisi altında kıyma sıkılır ve sürekli olarak çıkıştan makineden dışarı boşaltılır.

Dondurulmuş et öğütme makinesinin performansı

Et öğütme makinesi, et üretim endüstrisinde yüksek derecede çok yönlülüğe ve geniş bir uygulama aralığına sahip bir et işleme ekipmanıdır. Endüstriyel dondurulmuş et öğütme makinesi, ham maddeyi, çiğ eti makinede itmek için vidanın hareketi altında ileri doğru iter. hazne kutusunu ön kesme ünitesine doğru ilerletin.

Dondurulmuş kıyma makinesinin özellikleri

- İdeal et dolgusu, delikli plakaların farklı kombinasyonları ile elde edilebilir.

- Dondurulmuş eti iyice kıyın.

- Pozitif ve negatif dönüş, kıyma kesicilerin malzemeyi bloke etmesini önler;

- Et kıyma ekipmanı çok yönlülük, geniş uygulama alanı ve yüksek verim ile karakterize edilir;

- Dondurulmuş eti kıyma ve öğütme işlevine sahiptir; zamandan, emekten tasarruf sağlar, tazeliği ve kaliteyi garanti eder;

- Kısa kesme süresi ve düşük çalışma sıcaklığı sayesinde, kıymanın raf ömrü uzatılarak tazeliği korunur;

- Çoklu delikli plaka kombinasyonları, çok çeşitli et ürünlerinin işlenmesine ilişkin gereksinimleri karşılayabilir.

Yorum Ekle