Badem kırma makinesi, kabuk kırma için profesyonel bir ekipmandır. Başta badem, kayısı, ceviz, şeftali, fındık vb. her türlü kuruyemiş kabuğunu soymak için kullanılır. Bileşenleri besleme hunisi, silindir, yerçekimi ayırıcı ve fanı içerir. Bu kuruyemiş kırıcı kompakt bir yapıya, basit bir kullanıma ve kararlı bir performansa sahiptir ve aynı zamanda dayanıklıdır. Müşteriler, farklı boyutlardaki farklı kuruyemişlere uyum sağlamak için aralığı ayarlayabilirler. İşlemden sonra badem tohumları sağlam kalabilir. Kabuklar ve çekirdekler için bir badem yerçekimi ayırıcı ile de eşleştirilebilir.

Badem soyma makinesinin avantajı

- Ceviz krakerinin kullanımı ve bakımı kolaydır. Operasyon sırasında sadece bir kişiye ihtiyaç duyulur.

- Badem, ceviz, kayısı vb. farklı kuruyemiş türleri için uygundur.

- Makine az yer kaplar ve üretim hattı oluşturmak kolaydır.

- Yüksek bombardıman oranı. Bombardıman oranı 98%'den fazladır, bu da tüm fındık kabuklarının kırılabileceği ve çok temiz çekirdekler elde edebileceğiniz anlamına gelir.

- Silindirin boşluğu farklı boyutlardaki somunlara uyacak şekilde ayarlanabilir.

- 1%'den daha düşük kırık oranı. Daha iyi bir çatlama etkisi elde etmek istiyorsanız operasyondan önce hemen hemen aynı büyüklükte somunların seçilmesi gerekmektedir.

- Kabuğu dolu olan fındıklar tekrar kırılabilir.

- Döner ve ayarlanabilir silindirler, bu fındıkkıranın çeşitli özelliklere sahip fındıklar için uygun olmasını sağlar

Badem soyma makinesinin teknik parametresi

| Modeli | SLBK-1 |

| Kapasite | 400kg/saat |

| Güç | 2.2KW |

| Boyut | 200*110*45cm |

| Ağırlık | 220kg |

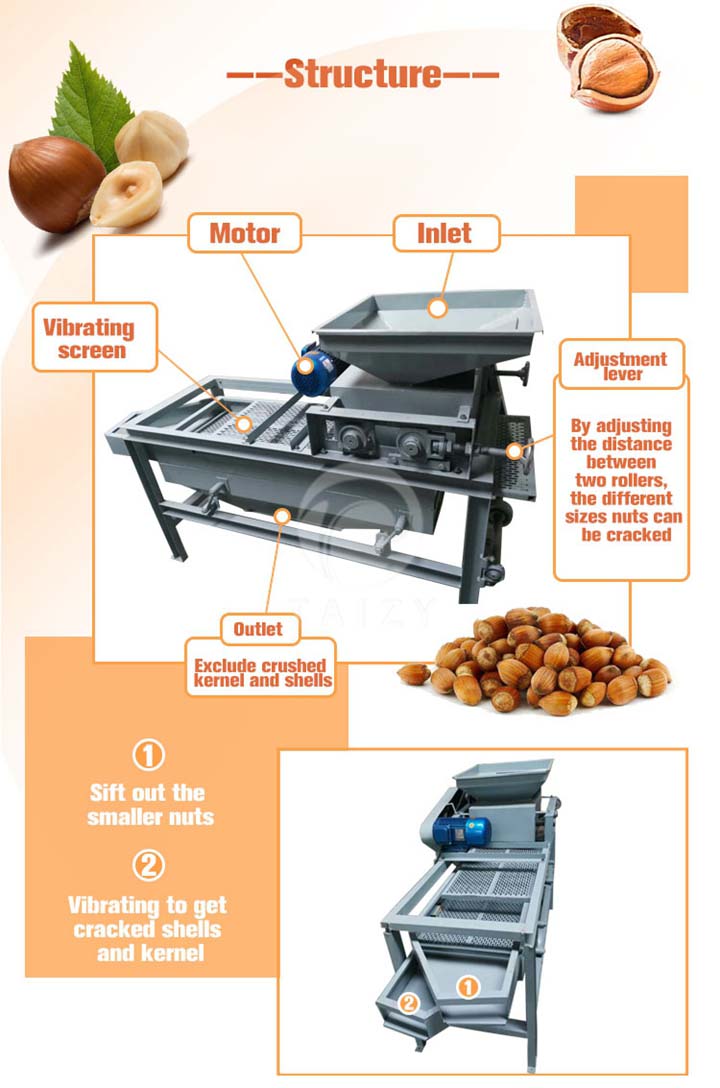

Çalışma prensibi fındık kırma makinesi

- Benzer büyüklükteki somunu badem kırma makinesine yerleştirin.

- Somunlar sürekli çarpışan, sürtünen, somunları sıkan iki silindirin boşluğundan aşağı düşer

- Kabuk ve iç çekirdek titreşimli elek üzerinde hareket eder, dış kabuk yukarı doğru hareket eder ve iç çekirdek aşağı doğru hareket eder.

- Son olarak farklı çıkış noktalarından deşarj edilirler.

Güney Afrika'da ceviz kırma makinesi

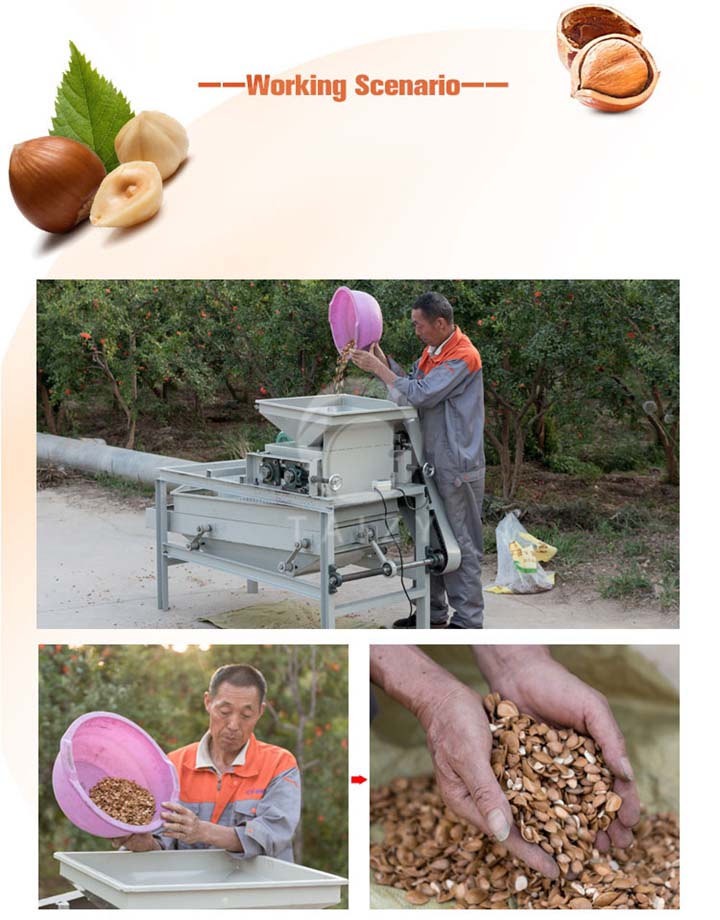

Mart 2019 sonunda Güney Afrikalı bir müşterimiz bize talepte bulundu. Kendisi fındık işleme fabrikasının olduğunu ve siyah cevizli bisküvi makinesi almak istediğini söyledi. Makinenin kalitesini artırmak için bir ay sonra (Nisan 2019) Çin’e geldi, kendisini havaalanından aldık ve ardından makine testi için fabrikamıza götürdük. Farklı ülkelerin boyutları farklı olduğu için Güney Afrika'dan biraz ceviz satın aldı. Çalışanlarımız operasyondan önce silindirlerin aralığını hammaddenin boyutuna uyacak şekilde ayarladı. Kendi testinin ardından bu ceviz kırıcının mükemmel kırma etkisi karşısında şok oldu ve fabrikası için gerçekten satın almak istediği makinenin bu olduğunu söyledi. Fabrikamızdan ayrılırken 5 makinenin depozitosunu ödedi.

Bu ceviz soyma makinesi ona büyük karlar kazandırdı ve Temmuz ayı sonunda tekrar 10 set sipariş etti. Fabrikamızla uzun vadeli bir işbirliği ilişkisi kurmayı umduğunu söyledi.

Badem soyma makinesi hakkında sıkça sorulan sorular

1. Bu fındıkkıranın hammaddesi nedir?

Badem, kayısı, ceviz gibi çeşitli kuruyemişleri kırabilmektedir.

2. İki silindir arasındaki boşluğu ayarlayabilir miyim?

Evet ayarlanabilir.

3. Neden çoğu yemişin işlendikten sonra hala kabuğu var?

İki merdane arasındaki boşluk uygun olmadığından aralarındaki boşluğun kısaltılması gerekir.

4. Neden bu kadar çok kırık çekirdek var?

Çünkü iki silindir arasındaki boşluk çok küçük.

5. Kabuğu somunu iki kez kırmak için kullanabilir miyim?

Eğer bazı küçük ebatlı somunlar işlendikten sonra hala kabukluysa, merdaneler arasındaki boşluğun ayarlanması ve tekrar çatlatılması gerekir.

6. Çatlama oranı nedir?

Çatlama oranı 98%'den daha yüksektir.