เครื่องคัดแยกไข่อัตโนมัติเรียกอีกอย่างว่าอุปกรณ์คัดแยกไข่ โดยจะใช้น้ำหนักไข่ในการคัดแยกอัตโนมัติ ตามข้อกำหนดการให้คะแนนที่แตกต่างกัน เครื่องคัดแยกไข่สามารถแบ่งไข่ออกเป็น 5 และ 7 ระดับ ช่วงการให้เกรดจะถูกปรับแต่งตามความต้องการของลูกค้า เครื่องคัดแยกไข่ขนาดเล็กมีทั้งรุ่นสแตนเลสและรุ่นเหล็กคาร์บอน มีฟังก์ชั่นการขนส่งอัตโนมัติ การจุดเทียน และการให้คะแนน สิ่งอำนวยความสะดวกที่สนับสนุนสำหรับการแปรรูปไข่ในฟาร์ม ได้แก่ เครื่องล้างไข่ อุปกรณ์ดูดไข่ เครื่องพิมพ์ไข่ เครื่องบรรจุไข่ และอื่นๆ เครื่องคัดแยกไข่ของ Taizy ถูกนำมาใช้กันอย่างแพร่หลายในการคัดแยกไข่ไก่ ไข่เป็ด ไข่ห่าน ไข่กวน ไข่นกกระทา ฯลฯ

เครื่องคัดแยกไข่คืออะไร?

เครื่องคัดแยกไข่เชิงพาณิชย์เป็นอุปกรณ์แปรรูปไข่แบบชั่งน้ำหนัก เครื่องคัดเกรดจะส่งไข่ไปยังกล่องเก็บไข่ที่แตกต่างกันโดยอัตโนมัติเพื่อคัดเกรดตามน้ำหนักหรือขนาดของไข่ นอกจากฟังก์ชั่นการคัดเกรดแล้ว เครื่องคัดเกรดไข่ยังมีฟังก์ชั่นการตรวจสอบด้วยแสง ซึ่งสามารถตรวจจับไข่ตัวอ่อน ไข่ที่มีรอยแตก และไข่ที่มีสีไม่สม่ำเสมอ ปัจจุบันมีเครื่องคัดแยกไข่สองประเภทหลักที่พัฒนาโดย Taizy

เครื่องคัดไข่มีหน้าที่อะไร?

ตัวเครื่องมีอุปกรณ์ดูดไข่ที่สามารถช่วยในการคัดแยกไข่ได้อย่างรวดเร็ว ถ้วยดูดแบบมือถือจะดูดไข่ออกจากถาดไข่ สามารถบรรจุไข่ได้ครั้งละ 30 ฟอง ซึ่งจะช่วยประหยัดแรงงาน

เครื่องลำเลียงไข่อัตโนมัติสามารถขนส่งไข่ไปยังเครื่องคัดแยกไข่เพื่อคัดเกรดได้อย่างรวดเร็ว เครื่องเคลื่อนย้ายได้อย่างราบรื่นโดยไม่ทำให้ไข่เสียหาย ลูกกลิ้งซิลิโคนของสายพานลำเลียงไข่พร้อมแถบนำทางช่วยให้มั่นใจได้ว่าไข่จะเคลื่อนที่ด้วยความเร็วคงที่ในรางนำทาง

อุปกรณ์ตรวจจับไฟ LED ของเครื่องคัดแยกไข่ติดตั้งอยู่ใต้ลูกกลิ้งลำเลียงไข่ เมื่อไข่ผ่านพื้นที่ตรวจสอบด้วยแสง พนักงานสามารถผ่านการตรวจสอบด้วยแสงเพื่อคัดแยกไข่ที่เสียหาย ไข่ตัวอ่อน ไข่ของเพศตรงข้าม และไข่ที่ไม่ผ่านการรับรองอื่นๆ

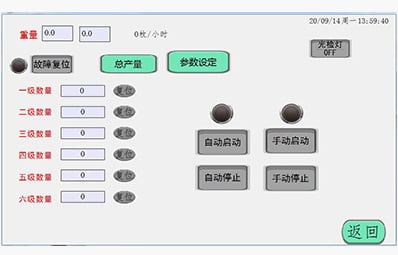

เครื่องคัดเกรดอิเล็กทรอนิกส์ PLC หน้าจอสัมผัสสีของเครื่องคัดเกรดไข่มีฟังก์ชั่นการวินิจฉัยตัวเอง ซึ่งสามารถนับจำนวนไข่ที่จัดเรียงในแต่ละระดับในแต่ละคลาสได้อย่างชาญฉลาด และความแม่นยำในการให้คะแนนคือ ± 1 กรัม ข้อความบนหน้าจอสัมผัสสามารถเลือกภาษาต่างๆ ได้ เช่น อังกฤษ จีน ฝรั่งเศส ฯลฯ

คนเก็บไข่สามารถปรับลำดับของไข่ที่คัดเกรดแล้ววางไข่ที่เกี่ยวข้องลงในรังไข่แบบพิเศษ จากนั้นจึงใส่ไข่ลงในถาดไข่ด้วยตนเองโดยใช้อุปกรณ์ดูดไข่

การใช้งานเครื่องคัดแยกไข่

เครื่องคัดไข่มีการใช้งานที่หลากหลายและสามารถใช้ได้กับฟาร์มขนาดต่างๆ เช่น ฟาร์มไก่ ฟาร์มเป็ด ฟาร์มห่าน เป็นต้น นอกจากนี้ เครื่องคัดแยกไข่ยังใช้ในโรงงานแปรรูปไข่ลึกและขนาดใหญ่อีกด้วย ซุปเปอร์มาร์เก็ตเพื่อคัดเกรดไข่ โรงฟักไข่สัตว์ปีกบางแห่งยังเลือกเครื่องคัดแยกไข่เพื่อเตรียมไข่ไว้ล่วงหน้า สุดท้ายนี้ เครื่องคัดแยกไข่ยังมักใช้ในโรงงานแปรรูปอาหารต่างๆ โดยเฉพาะโรงงานอาหารจากไข่ เพื่อให้มั่นใจถึงน้ำหนักของไข่ที่สม่ำเสมอ จึงมักเลือกผู้คัดเกรดเพื่อแปรรูป

TZ-4000 เครื่องคัดแยกไข่ขนาดเล็ก

| แบบอย่าง | TZ-4000 |

| แรงดันไฟฟ้า | 220v,50hz |

| ความจุ | 4000 ชิ้น/ชม |

| ขนาด | 1.7*1.45*1ม |

| เกรด | 7 |

| การทำงาน | การคัดเกรดไข่และการจุดเทียน |

เครื่องคัดแยกไข่ขนาดเล็กนี้มักใช้ในครัวเรือนและฟาร์มขนาดเล็กเพื่อคัดแยกไข่ ไข่เป็ด ไข่ห่าน ฯลฯ อย่างรวดเร็ว อุปกรณ์คัดแยกไข่เป็นที่นิยมในตลาดเนื่องจากมีขนาดเล็ก ต้นทุนต่ำ และประสิทธิภาพการประมวลผลสูง มักส่งออกไปยังฟิลิปปินส์ อินเดีย ออสเตรเลีย สหรัฐอเมริกา ปากีสถาน เคนยา โรมาเนีย และประเทศอื่นๆ เครื่องคัดแยกไข่ขนาดเล็กมีฟังก์ชั่นการตรวจสอบด้วยแสง การชั่งน้ำหนักอัตโนมัติ และการคัดเกรดอัตโนมัติ และความสามารถในการแปรรูปอยู่ที่ประมาณ 3,500-4,000 ชิ้นต่อชั่วโมง

TZ-5400 เครื่องคัดแยกไข่อัตโนมัติ

| แบบอย่าง | TZ-5400 |

| แรงดันไฟฟ้า | 220v,50hz |

| ความจุ | 5400 ชิ้น/ชม |

| ขนาด | 1.85*1.6*1ม |

| เกรด | 5 |

| การทำงาน | การคัดเกรดไข่และการจุดเทียน |

อุปกรณ์คัดแยกไข่อัตโนมัตินี้เหมาะสำหรับโรงงานสัตว์ปีกขนาดใหญ่เนื่องจากมีผลผลิตสูงกว่า ผลผลิตของเครื่องคัดเกรดนี้สามารถเกิน 5,000 ฟองต่อชั่วโมง ซึ่งเหมาะมากสำหรับผู้ใช้ที่มีการแปรรูปไข่จำนวนมาก ปัจจุบันเครื่องคัดแยกไข่ขนาดใหญ่นี้ส่งออกอย่างกว้างขวางไปยังแอฟริกาใต้ ซูดาน ไนจีเรีย ตุรกี สเปน สหราชอาณาจักร แคนาดา อาร์เจนตินา ฯลฯ เครื่องคัดแยกไข่นี้สามารถจำแนกไข่ได้เป็น 5 เกรด นอกจากนี้เครื่องคัดแยกอัตโนมัติมักใช้กับอุปกรณ์โหลดไข่อัตโนมัติ เครื่องล้างไข่, เครื่องพิมพ์ไข่และเครื่องบรรจุไข่

หมายเหตุของเครื่องคัดแยกไข่ Taizy

- เครื่องคัดแยกไข่สองประเภทข้างต้นมีรุ่นเหล็กคาร์บอนและสแตนเลส ราคาของอุปกรณ์คัดแยกไข่ที่วัสดุต่างกันจะแตกต่างกัน

- แรงดันไฟฟ้าของเครื่องคัดแยกไข่ทั้งสองชนิดนี้สามารถปรับแต่งได้ตามเงื่อนไขแรงดันไฟฟ้าในพื้นที่ของลูกค้า นอกจากนี้ เกรดการให้เกรดของตัวแยกประเภทยังสามารถปรับแต่งได้ตามความต้องการของลูกค้า

- วิธีการทำงานของเครื่องคัดแยกไข่ทั้งสองเครื่องนั้นง่ายมาก และต้องใช้คนงานเพียง 1-2 คนในการทำงานจริง

วิธีการคัดแยกไข่ด้วยเครื่องคัดแยกไข่?

1. ใส่ไข่ด้วยตนเอง: วางไข่บนสายพานลำเลียงด้วยตนเอง จะใส่ไข่ทีละฟอง หรือใช้เครื่องดูดไข่เพื่อบรรจุไข่อย่างรวดเร็ว

2. การจุดเทียน: อุปกรณ์การจุดเทียนติดตั้งอยู่ตรงกลางสายพานลำเลียง อุปกรณ์ตรวจสอบด้วยแสงจะฉายรังสีไข่จึงสามารถเลือกไข่ที่ไม่เข้าเกณฑ์ เช่น รอยแตก สีเหลือง และ ความผิดปกติ.

3. การให้เกรด: ไข่จะเข้าสู่พื้นที่คัดเกรดผ่านสายพานลำเลียง พื้นที่คัดเกรดใช้ระบบชั่งน้ำหนักเชิงกลเพื่อคัดเกรดไข่ที่มีน้ำหนักต่างกัน

4. การรวบรวมไข่: ไข่ที่ให้คะแนนแล้วจะถูกทิ้งลงบนกระดานให้คะแนน และไข่ที่มีเกรดต่างกันจะถูกรวบรวมด้วยตนเอง

คุณสมบัติของเครื่องคัดแยกไข่ไก่

- มีจำหน่ายในวัสดุเหล็กคาร์บอนและสแตนเลส

- เครื่องคัดแยกไข่ถูกนำมาใช้กันอย่างแพร่หลายในการคัดแยกไข่สด ไข่เป็ด ไข่เค็ม ไข่ห่าน ไข่เยี่ยวม้า ฯลฯ

- ใช้โครงสร้างเฟืองลูกเบี้ยวและระบบส่งกำลังแบบโซ่ เพื่อให้สามารถชั่งน้ำหนักไข่ตามลำดับและไม่เสียหาย

- สามารถติดตั้งเครื่องทำความสะอาดไข่ เครื่องพิมพ์ไข่ และเครื่องแปรรูปไข่อื่นๆ เพื่อสร้างสายการผลิตไข่

- ติดตั้งอุปกรณ์ตรวจสอบด้วยแสงเพื่อตรวจจับคุณภาพของไข่ผ่านการตรวจสอบด้วยแสง

- ใช้การลำเลียงแบบมีด หลักการชั่งน้ำหนักแบบคันโยก การชั่งน้ำหนักที่แม่นยำ และการปรับที่สะดวก

วิดีโอการทำงานของเครื่องคัดแยกไข่

เครื่องจักรแปรรูปไข่ที่เกี่ยวข้องสำหรับโรงงานคัดแยกไข่

เครื่องล้างไข่

เครื่องพิมพ์ไข่

เพิ่มความคิดเห็น