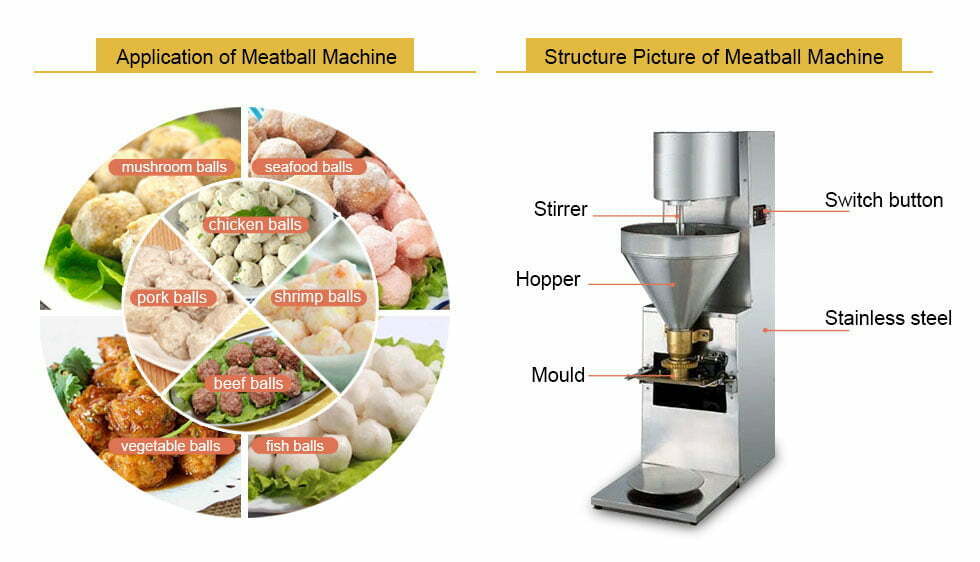

A máquina comercial para fazer almôndegas é uma máquina especialmente utilizada para formar almôndegas. A máquina para fazer almôndegas é fácil de operar e é amplamente utilizada na formação de bolinhos de peixe, bolinhos de carne, bolinhos de porco, bolinhos de frango e outros produtos. Substitui completamente a moldagem manual anterior e pode produzir cerca de 300 peças em um minuto com alta produtividade. O tamanho das almôndegas formadas pode ser personalizado de acordo com a necessidade do cliente. Além disso, a velocidade de descarga e o tamanho dos pellets moldados podem ser controlados. A máquina comercial de formação de almôndegas adota materiais de qualidade alimentar, e as almôndegas são seguras e higiênicas e podem ser consumidas com confiança. A máquina para fazer almôndegas é durável, fácil de limpar e tem uma longa vida útil.

Vídeo de máquina comercial de fazer almôndegas

Breve introdução à máquina de fazer almôndegas

A máquina industrial para fazer almôndegas é composta por um moedor de carne, um batedor e uma máquina de moldagem. De acordo com os diferentes tipos de almôndegas, o batedor se divide em batedores de alta velocidade e batedores de baixa velocidade.

Tomando como exemplo a carne de porco, a carne é primeiro limpa e cortada em pedaços pelo moedor. Em seguida, coloque-o em uma batedeira de alta velocidade para obter a carne picada. Finalmente, molde-o em uma máquina de moldagem.

A máquina formadora de almôndegas adota aço inoxidável e o diâmetro é de 12-35 mm. A quantidade de recheio pode ser ajustada livremente para fazer todos os tipos de almôndegas crocantes, duras e elásticas.

Princípio de funcionamento da máquina comercial de fazer almôndegas

- Conecte a fonte de alimentação e o tubo de água na parte traseira do almôndega máquina criadora.

- Há um botão de ajuste de volume da carne próximo à manga de cobre para alterar a redondeza das almôndegas. A almôndega fica mais comprida se a carne for excessiva e achatada se a carne for insuficiente. A máquina não funciona quando a pasta de carne no barril não é suficiente.

- Coloque uma bacia com água morna embaixo da saída das almôndegas.

- Coloque o purê de carne no balde, abra o cano de água na placa deslizante para liberar água, depois abra a máquina e coloque as almôndegas no balde.

- Após o processamento, a haste empurradora, o balde de carne, a luva de cobre e a placa de cobre devem ser retirados para limpeza.

- Verifique se a mola interna da máquina está disponível após um longo período de uso.

A perspectiva de máquinas para fazer almôndegas

Almôndegas são alimentos esféricos feitos de carne picada e são populares entre os consumidores. As almôndegas tradicionais são feitas à mão. Com o desenvolvimento da tecnologia, o equipamento para almôndegas não apenas alivia o fardo das pessoas, mas também melhora muito a eficiência da produção de almôndegas.

Vantagem da máquina formadora de almôndegas

1. Alta capacidade: pode produzir 195 ~ 280 almôndegas por minuto.

2. Pode fazer almôndegas, bolinhos vegetarianos e bolinhos de peixe.

3. As almôndegas e bolinhos de peixe produzidos são elásticos e coloridos.

4. o tamanho das bolas é ajustável.

Parâmetro técnico da máquina automática de fazer almôndegas

| Modelo | TY-400 |

| Poder | 1.500 kW |

| Tensão | 220/380 V |

| Peso | 160kg |

| Dimensão | 400*550*1280mm |

Adicionar comentário