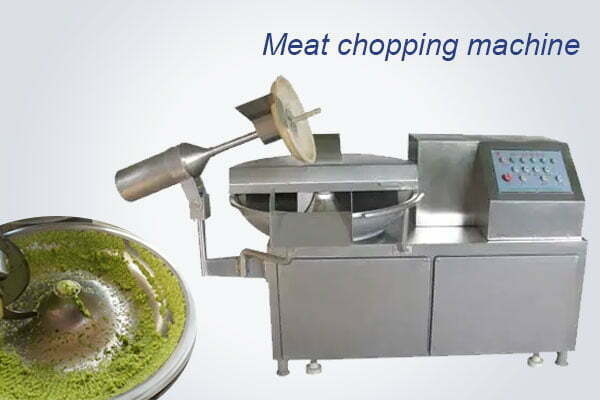

Industrial meat bowl chopper machine application

The industrial meat bowl chopper machine is a machine specially used to cut vegetables and meat into paste-like substances. It equips with high-speed rotating chopper can mince the meat, seasoning materials, fat, and other main raw materials into the minced mixture. At the same time, through the chopping blending of the minced meat and other raw materials such as water, ice scraps, and flavoring materials are stirred together to form a paste. High-speed rotation of the cutting knife shortens the stirring time, so as to create less heat in the materials, so as to maintain the natural color, elasticity, yield and shelf life of the final products. This machine is widely used in the food industry for meat, vegetables, and seafood seasoning and mixing.

Advantage of meat bowl cutter

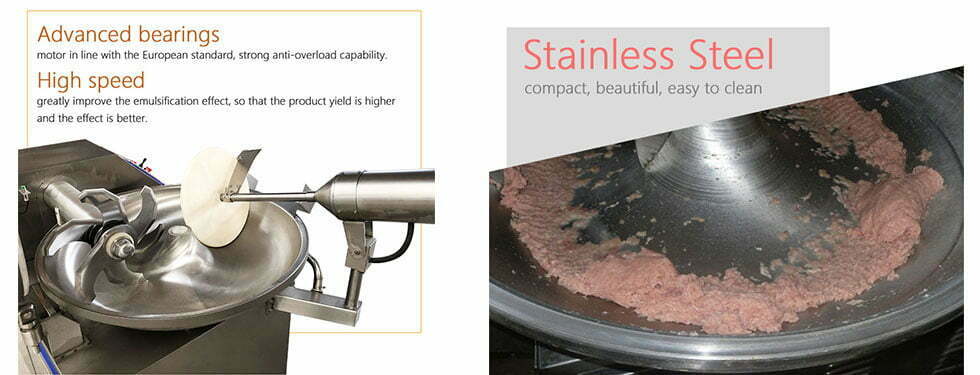

1. Through stirring and emulsifying, the blending machine prevents raw materials from being damaged by oxidation and destruction of myoglobin, fat and other nutrients in raw meat, thus the original color, flavor, and various nutrients maintained to its utmost. This machine has the characteristics of high rotating speed cutter shaft, powerful stirring, good emulsifying and cutting effect, a wide range of applicable raw materials.

2. It can not only chop and stirring all kinds of meat but also cut and emulsify raw materials including crude fiber and combined collagen such as skin and tendons. The meat chopping and blending machine adopts advanced electric speed and operating controller ensures safe and reliable working, convenient and low maintenance, and complete display and control system. The motor has the characteristics of large starting torque, ideal heat insulation and heat resistance, reliable overload protection, which is suitable for meat blending and mixing under a circumstance of frequent starting.

3. The meat bowl cutter is amounted of a frequency conversion motor to achieve the most suitable controlling effect, so that the chopper mixer can be given full paly at any speed, and more save your electric bill and there is no impact on the power grid. The different tool with various speed can be accurately displayed in the display panel.

4. Automatic monitoring can reduce the work intensity, and control and decrease the frequency of failure, meanwhile, the execution of working sequence programs can greatly reduce the failure rate of equipment hardware and facilitate the maintenance.

Bowl with vegetable chopper configuration

1. The vegetable meat chopping machine adopts SUS304 stainless steel, which is characterized by reasonable structure, beautiful appearance, and easy maintenance. The transfer pot is made of casted stainless steel and equipped with overflow proof fringe to effectively prevent material overflowing.

2. Main parts are processed by rigidly trained engineers to ensure fine machining accuracy.

3. The blades are sharp and durable, stable high-speed running ensuring the good mixing emulsification effect.

4. The main axis adopts advanced installation method–double bearings tandem to ensure ideal concentricity of the cutter shaft set. The main axis is cast by high-frequency quenching (false tolerance less than 0.03mm). High-speed, stable and noiseless operation.

5. Speed can reach 4500 RPM, which greatly improve the emulsification effect, so that improve the product output rate with better effect.

6. The distance between the blade tip and the wok inner surface is no more than 2mm.

7. Adopt world-class motor gearbox and all electrical components to ensure the quality of the whole machine.

Parameter of industrial meat bowl chopper

| MODEL | ZB-20 | ZB-40 | ZB-80 |

| CAPACITY | 20L | 40L | 80L |

| OUTPUT | 10-15L | 20-25L | 60L |

| POWER | 1.85kw | 5.5KW | 13.8kw |

| VOLTAGE | 380V | 380V | 380V |

| BLADES NUMBER | 3 | 3 | 6 |

| CHOPPING RATE rpm | 1500-3000 | 1500-3000 | 1500-3300 |

| STIRRING RATE | 16r/min | 13r/min | 8/16r/min |

| DIMENSION mm | 770*650*980 | 1350*750*1200 | 1400×820×1130 |