캐러멜은 생산 라인을 취급합니다 캐러멜 간식을 생산하는 데 사용되며 PLC 운영 체제를 채택하여 완전 자동화를 실현합니다. 연속적으로 원료공급, 평탄화, 슬리팅, 크로스커팅이 가능합니다. 또한 레벨링 밀도를 조정할 수 있으며 제품 두께가 균일합니다. 주파수 변환 조정으로 절단 크기가 정확하고 모양이 좋습니다.

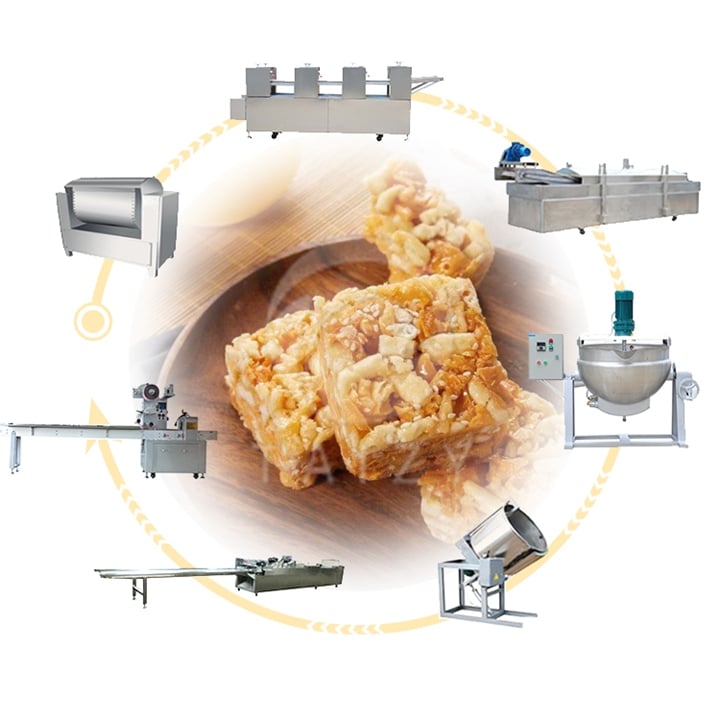

전체 캐러멜 취급 생산 라인은 지속적으로 생산되며 이 과정에서 수동 연결이 필요하지 않아 자동 및 지능형 작동이 완전히 실현됩니다. 캐러멜 처리 생산 라인에는 반죽 혼합기, 반죽 압착기, 기름 튀김기, 설탕 요리 냄비, 향료 혼합기, 절단 및 성형기, 포장기 등 7개의 기계가 필요합니다.

카라멜 취급 기계 작동 영상

캐러멜은 생산 과정을 취급합니다

반죽 믹서기

반죽 믹서기는 밀가루와 물, 계란을 섞는 기계이며, 이 기계에는 다양한 모델이 있으며 필요에 따라 하나를 선택할 수 있습니다. 반죽 섞는 시간은 3~10분 정도로 짧습니다.

| 모델 | 반죽의 무게(kg) | 반죽 혼합 시간(분) | 전압(v) | 전력(kw) | 기계(kg) | 치수(mm) |

| 12.5 | 12.5 | 3-10 | 220/380 | 1.5 | 100 | 650*400*730 |

| 25 | 25 | 3-10 | 220/380 | 1.5 | 128 | 685*480*910 |

| 37.5 | 37.5 | 3-10 | 220/380 | 2.2 | 175 | 840*480*910 |

| 50 | 50 | 3-10 | 220 | 2.2 | 230 | 1070*570*1050 |

| 380 | 2.575 | 275 | ||||

| 75 | 75 | 3-10 | 380 | 3.75 | 475 | 1410*680*1250 |

| 100 | 100 | 3-10 | 380 | 3.75 | 490 | 1520*680*1250 |

| 150 | 150 | 3-10 | 380 | 6.25 | 700 | 1710*730*1400 |

반죽 누르는 기계

반죽 누르는 기계는 반죽을 평평한 모양으로 누른 다음 작은 블록으로 자르는 것입니다.

기름튀김기

절단 후 작은 반죽 블록을 튀겨야 먹을 수 있습니다.

설탕 요리 냄비

설탕 냄비는 과립 설탕을 녹여 페이스트 형태로 만든 다음 작은 반죽 블록에 견과류, 참깨, 설탕 등의 재료를 함께 섞는 것입니다.

향미 블렌더

캐러멜 간식의 맛을 더 좋게 만들고 싶다면 향미 블렌더를 사용하여 표면에 약간의 양념을 뿌리면 됩니다. 양념은 필요에 따라 만드시면 됩니다.

성형 및 절단기

성형 및 절단 기계에는 2개의 압착 롤러와 3개의 냉각 팬이 있으며, 전자는 원료를 평평한 모양으로 누르고 후자는 캐러멜을 냉각시키는 것입니다. 최종 캐러멜은 모양이 균일하고 크기도 동일합니다.

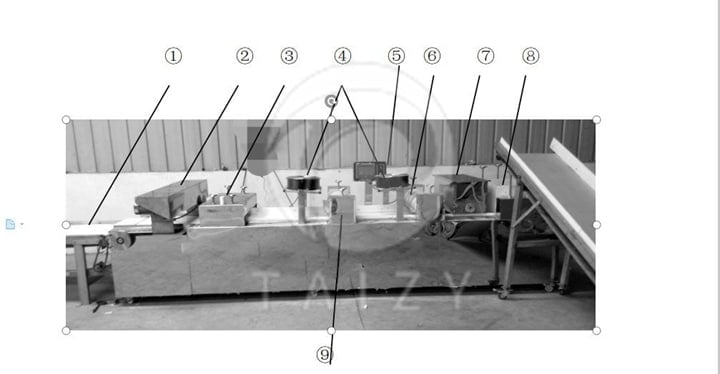

절단 및 성형 기계의 구조

1. 포장기까지의 컨베이어 벨트

2. 교차 절단 칼날

3. 슬리팅 블레이드, 프레싱 롤러

4. 냉각팬

5. 메인 제어판

6.1차 압착 롤러

7. 성분 살포기

8. 호퍼 공급

9.2차 압착 롤러

- 메인프레임 속도 표시

- 생산수

- 명확한 생산

- 시간 및 날짜 표시

- 메인프레임 매개변수 설정

- 컨베이어 벨트 주파수 표시(0-50)

- 메인프레임 시작 버튼

- 메인프레임닫기 버튼

- 동적 디스플레이

- 왼쪽 절단 길이(0-999)

- 오른쪽 절단 길이(0-999)

- 냉각팬 정지 버튼

캐러멜은 포장 기계를 취급합니다

포장기는 모든 식품 압착 라인의 마지막 단계이며 캐러멜 간식을 작은 봉지에 포장할 수 있습니다.

카라멜 간식을 얻는 방법?

1. 부풀리고 저은 쌀, 밀, 땅콩, 견과류 및 기타 재료를 공급기를 통해 주 기계 공급 호퍼에 넣습니다.

2. 두 개의 압착 롤러가 자동으로 원료를 평평하게 만듭니다.

3. 그런 다음 설정된 요구 사항에 따라 교차 절단 및 슬리팅을 수행하기 위해 컨베이어 벨트를 통해 자동 절단 부품으로 운반됩니다.

4. 이 과정에서 냉각팬에 의해 냉각된 후 절단된 소재는 컨베이어 벨트를 통해 포장기로 보내져 자동 포장됩니다.

캐러멜의 기술 매개변수는 생산 라인을 처리합니다.

| 모델 | TZ-SCX01 |

| 힘 | 380V/50HZ 3kw |

| 차원 | 6000*1300*1200mm |

| 무게 | 1050kg |

| 용량 | 150-300kg/h |

| 출력의 무게 | 5g~300g |

샤키마 가공기의 장점

- 메인 제어 회로는 수입된 단일 칩 마이크로컴퓨터, 인간-기계 인터페이스 및 주파수 변환 제어를 채택합니다. 매개변수를 설정하는 것이 편리하고 빠릅니다.

- 작업은 중앙집중적이고 직관적이며 인간화된 자동 제어를 완벽하게 실현합니다.

- 고감도 전자눈은 자동으로 추적이 가능하고 피드백 정보가 정확해 오차가 적다.

- 안정적인 작동, 자동 성형, 자동 이송 및 절단.

- 조작이 간단하고 노동강도가 낮습니다.

- 지속적인 생산 및 생산량이 매우 높습니다.

- 기계식 변속기 시스템은 컴팩트하고 레이아웃이 합리적입니다.

- 회로가 명확하여 이해하고 조작하기 쉽습니다.

| 부조 | 이유 | 해결책 |

| 전원을 켠 후 제어판에 불이 들어오지 않습니다. | 전원이 연결되어 있지 않습니다. | 전원을 확인하고 수집하십시오. |

| 카라멜 간식은 완전히자를 수 없습니다. | 블레이드와 컨베이어 벨트 사이의 간격이 너무 큽니다. | 칼날 높이를 조정하세요.

|

| 최종 캐러멜의 두께가 고르지 않습니다. | 누르는 롤러의 간격은 비례하지 않습니다 | 비례적으로 간격을 조정합니다. |

캐러멜 취급 생산 라인을 설치하는 방법은 무엇입니까?

A. 설치 조건

1. 캐러멜 취급 라인은 직사광선을 피하여 실내에 설치해야 합니다.

2. 지반은 시멘트 바닥으로 포장하고, 수돗물 공급원과 배수시설을 갖추어야 한다.

3. shaqima 가공 기계는 통풍이 잘되고 공기 압축기가 장착되어 있으며 압력 범위는 0.2Mpa-0.8Mpa입니다.

4.샤키마 가공 기계 필요한 조명 시설과 380V 전원 공급 장치가 있어야 합니다.

나. 설치시 주의사항

1. 설치장소는 원칙적으로 수돗물 공급원에 가까운 곳을 선정합니다.

2. 설치시 유지보수가 용이하도록 일정한 공간을 확보해 주시기 바랍니다.

3. 공장에서 장착된 부품은 포장을 푼 후 다시 확인하고, 헐거워진 부품이 있는지 조여주십시오.