전동소시지 결속기는 천연 케이싱과 훈제 케이싱으로 만든 소시지 제품에 적합합니다. 주로 엔에마 후 소시지를 묶는 데 사용됩니다. 자동 소시지 결속 와이어 기계는 자동화 수준이 높으며 분당 800개의 소시지를 결속할 수 있습니다. 소시지 와이어 길이는 생산 요구 사항에 따라 조정할 수 있습니다. 매듭 기계는 소시지 충진기, 훈연기 및 기타 제품과 함께 장착하여 소시지 생산 라인을 구성할 수 있습니다. 전체 기계는 스테인리스 스틸을 채택하여 작동 및 청소가 편리합니다.

소시지 결속기의 간략한 소개

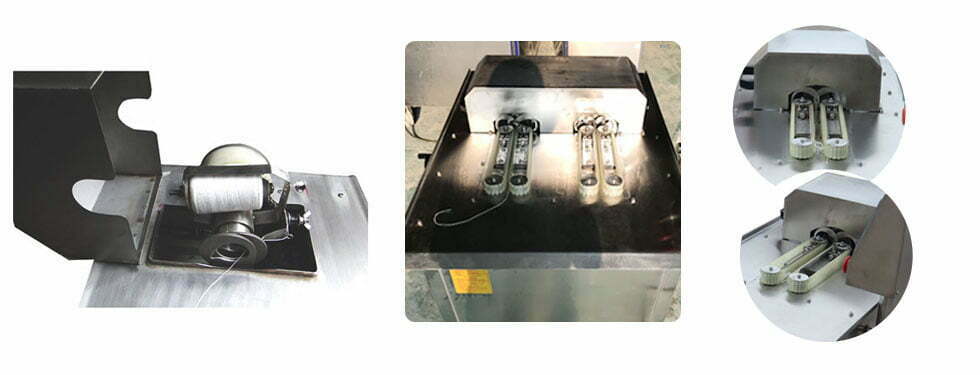

이 생산 라인에서 중요하고 가공되는 부분은 이중 배출 기계를 갖춘 완전 자동 소시지 결속 기계입니다. 소시지는 특정 길이로 절단될 수 있습니다. 이 기계의 가장 큰 장점은 라인 제품에 수동 및 기계적 절단이 필요하지 않다는 것입니다.

소시지 결속 와이어 기계는 작동이 매우 간단하며 길이와 속도를 설정한 후 모든 작업을 자동으로 효율적으로 완료할 수 있습니다. 최대 용량은 분당 600개이며, 생산 속도를 높이고 투자 비용을 절감할 수 있습니다.

소시지 매듭 묶는 기계의 종류

1. 매장에서는 수동으로 사용할 수 있습니다.

2. 공압식은 전기가 필요하지 않지만 가스 공급원에 연결됩니다.

3. 반자동 터치스크린 소시지 매듭 묶는 기계는 절차를 설정한 다음 소시지를 수동으로 넣을 수 있습니다.

4. 전자동 단일 출구형과 자동 이중 출구형은 절차를 설정해야 합니다.

소시지 바인딩 기계의 기능

이는 주로 모든 종류의 소시지를 묶는 데 적합하며 식품 가공 시장에서 이상적인 생산 장비로 간주됩니다.

소시지 결속기의 장점

- 인간-기계 인터페이스 제어 시스템을 채택하여 고효율, 긴 수명 및 쉬운 작동을 보장합니다.

- 제품 길이 및 출력에 대한 디지털 조정으로 자유로운 제어가 가능합니다.

- 소시지를 손상시키지 않는 고급 바인딩 메커니즘.

- 작업 강도가 완화됩니다. 작업자는 원료를 소시지 와이어 바인딩 기계에 넣으면 자동으로 바인딩 프로세스가 완료됩니다.

댓글 추가