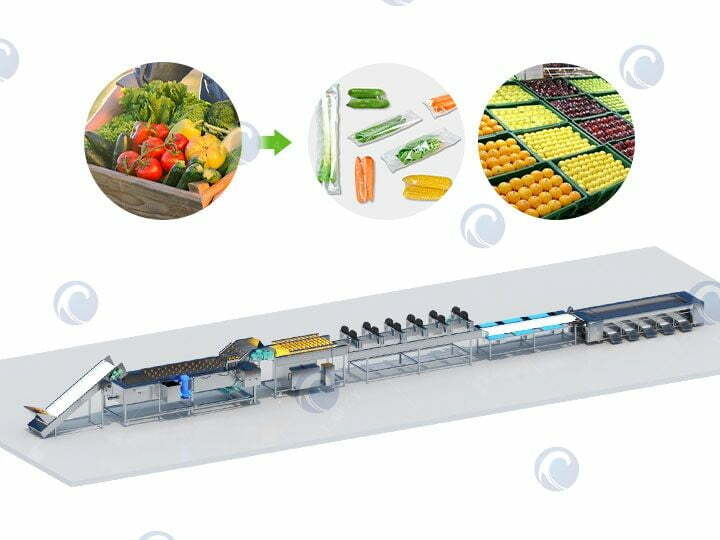

상업용 과일 및 야채 세척 건조 등급 분류 라인은 주로 대량의 과일 및 야채 처리를 자동화하는 데 사용됩니다. 10분 이내에 완전한 가공 과정을 마친 과일과 채소는 농장에서 슈퍼마켓으로 직접 판매될 수 있습니다. 과일 및 야채 세척 및 등급 지정 라인은 모든 종류의 과일 및 야채를 처리하고 불순물을 효과적으로 처리하며 불량 과일을 분류하고 가공을 위해 자동으로 등급을 매기고 포장할 수 있습니다. 자동 과일 및 채소 세척, 건조 및 등급 분류 라인의 처리 용량은 일반적으로 500kg/h~5000kg/h입니다. 우리 공장은 고객의 특정 요구와 원자재에 따라 비용 효율적인 가공 공장을 맞춤화할 수 있습니다.

야채 세척 건조 등급 라인을 선택하는 이유는 무엇입니까?

깨끗한 야채에 대한 대규모 시장 수요

오늘날 과일 및 야채 슈퍼마켓, 대형 매점, 식품 가공 공장에서는 깨끗한 야채에 대한 수요가 매우 높습니다. 결과적으로 많은 과일 및 채소 농장에서는 더 이상 갓 수확한 과일 및 채소 제품을 시장에 직접 판매하지 않고 과일 및 채소 가공 장비를 사용하여 과일 및 채소를 깨끗하고 잘 포장된 야채로 가공하기로 선택합니다. 이러한 코코아 가공방법은 과일 및 채소 제품의 부가가치를 크게 높여 시장에서 더욱 대중화되고 있습니다.

높은 처리 효율성과 저렴한 비용

과일 및 야채 제품을 처리하기 위해 많은 육체 노동자를 고용하는 것과 비교할 때 과일 및 야채 세척 건조 등급 포장 라인 전체 세트를 구매하면 처리 효율성이 크게 향상되고 많은 작업자의 비용을 절감할 수 있습니다.

과일 및 야채 세척 건조 등급 라인 세부 정보

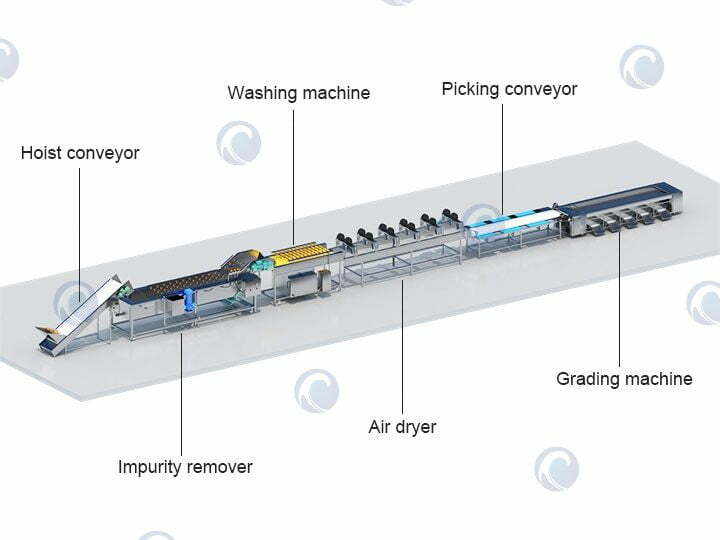

과일 및 야채 가공 라인의 설계는 일반적으로 모든 종류의 과일 및 야채를 처리하는 모든 종류의 식품 가공 공장, 과일 및 야채 슈퍼마켓, 레스토랑 등에 적용될 수 있습니다. 본 생산라인에 포함된 주요 장비로는 자동 리프팅 기계, 버블 세척기, 불순물 제거기, 에어 드라이어, 피킹 테이블, 자동 과일 및 야채 등급 기계, 클린 야채 포장 기계 등이 있습니다.

깨끗한 야채와 과일을 가공하는 단계

원료 들어올리기

우선, 자동 엘리베이터에 세척해야 할 야채나 과일을 차례로 추가해야 합니다. 엘리베이터는 균일한 속도로 청소를 위해 버블 와셔로 이동합니다. 엘리베이터의 운반 속도는 처리 요구에 따라 조정될 수 있습니다.

야채 및 과일 세척

세척 탱크 아래의 와류 발생기 기포 와셔 과일과 야채를 빠르게 세척하기 위해 물에 많은 거품을 생성합니다. 버블 와셔 끝에는 서핑 장치가 있어 재료가 앞으로 넘어질 수 있습니다. 세척 과정에서 원자재가 손상되지 않습니다.

불순물 제거

거품세척으로 세척한 후, 불순물 제거기를 이용하여 과일, 야채 등의 추가 세척이 가능합니다. 이 불순물 제거기는 여러 개의 헤어롤러를 갖추고 있어 세척이 어려운 과일, 야채 표면도 깨끗하게 제거할 수 있습니다. 머리카락이나 모래와 돌.

공기 건조

에어 드라이어에는 여러 세트의 강력한 팬이 있어 과일과 야채 표면의 물방울을 빠르게 건조시킵니다. 공기 건조 후 과일과 채소를 추가로 포장하거나 등급을 매길 수 있습니다.

깨끗한 과일 및 야채 등급

자동 선별기는 무게, 직경, 크기 등 다양한 등급 치수에 따라 깨끗한 과일과 채소의 등급을 지정할 수 있습니다. 등급을 매긴 후 고객은 판매용 과일과 채소를 다양한 크기로 분류하고 표시할 수 있습니다. 등급 기계의 등급 수준은 고객의 요구에 따라 맞춤 설정할 수 있습니다.

빠른 포장

고객은 필요에 따라 등급이 매겨진 과일과 채소를 포장하기 위해 과일 및 채소 포장기를 선택할 수도 있습니다. 과일 및 채소는 진공 포장, 박스 포장, 열수축 필름 포장 등으로 포장할 수 있습니다.

과일 및 야채 등급 기계의 분류

매우 유능한 식품 기계 제조업체이자 공급업체로서 당사는 고객이 선택할 수 있는 다양한 과일 및 야채 등급 장비를 제공할 수 있습니다. 우리 공장에서 판매되는 과일 및 야채 등급 기계에는 직경 등급과 중량 등급의 두 가지 주요 유형이 있습니다.

직경에 따른 야채 및 과일 등급

유형 1

이 롤러 바 유형 과일 및 야채 등급 기계는 일반적으로 감자, 타로, 고구마, 토마토, 사과, 양파, 석류 등과 같은 모든 종류의 구근을 등급 지정하는 데 사용됩니다. 이 등급기의 등급 번호는 고객에 따라 맞춤 설정할 수 있습니다. 요구 사항은 일반적으로 4-7 등급입니다. 등급을 매길 때 과일과 채소는 해당 롤 바 사이의 간격에 도달하면 자동으로 해당 배출 직경 등급으로 떨어집니다.

감자 선별기 영상

유형 2

이 새로운 유형의 과일 및 채소 선별기는 직경에 따라 과일과 채소의 등급도 분류합니다. 그것은 오렌지, 블루베리, 자두, 성자 과일, 키위, 산사나무속, 대추야자 등과 같은 모든 종류의 과일을 등급을 매기는 데 더 일반적으로 사용됩니다. 그레이더의 등급 실린더는 PE 플라스틱으로 만들어졌으며 구멍 직경은 맞춤 설정할 수 있습니다. 이 자동 채점기의 채점 등급은 일반적으로 4~9등급입니다.

야채 및 과일의 무게별 등급

이 연속 과일 및 야채 선별 기계는 무게에 따라 등급이 매겨집니다. 이 산업용 등급 기계는 모든 종류의 과일과 채소를 우수한 등급 효율성으로 등급을 매기는 데 사용할 수 있습니다. 등급 기계는 일반적으로 자동 과일 수확기 로더와 함께 사용됩니다. 과일선별기에는 자동 계량 기능이 있어 과일과 채소를 무게에 따라 정확하게 등급을 매길 수 있습니다.

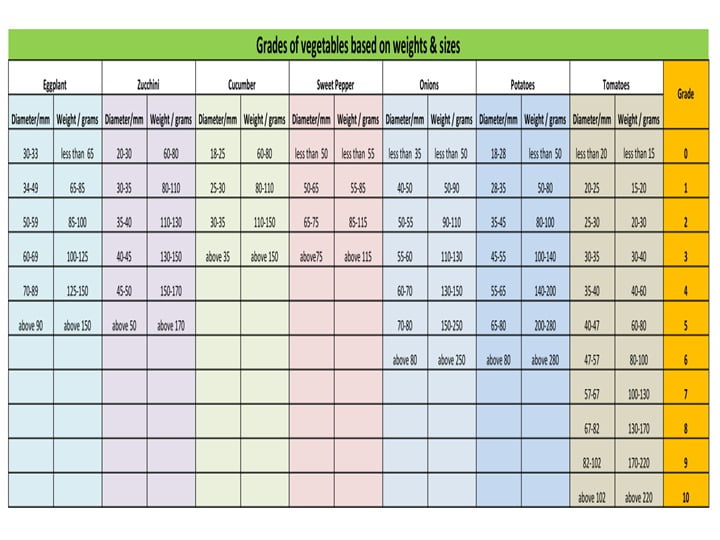

일반적인 과일 및 채소 등급 기준

과일 및 야채 세척 건조 등급 분류 라인에 권장되는 기계

깨끗한 야채 포장기

이 연속 포장 기계는 깨끗한 야채를 봉지나 상자에 포장하는 데 사용할 수 있습니다. 과일 및 야채 포장의 크기와 무게는 고객의 요구에 따라 설정될 수 있습니다.

플라스틱 바구니 청소 기계

이 산업용 플라스틱 바구니 세탁기는 신속한 청소 및 고온 살균을 위해 과일 및 야채 가공 공장의 모든 종류의 플라스틱 바구니 작업자를 대체할 수 있습니다.

야채 가공 공장의 응용

과일 및 야채 가공 공장의 전체 세트는 이제 냉동 야채 가공업체, 체인 슈퍼마켓 공급업체, 과일 및 야채 영지 재배자 등과 같은 많은 분야에서 널리 사용됩니다. 요즘 우리는 많은 국가와 지역에 과일을 수출했습니다. 이집트, 캐나다, 터키, 영국, 이탈리아, 프랑스, 캐나다, 미국, 카타르, 프랑스, 그리스 인도네시아, 사우디 아라비아, 호주 등과 같은 많은 국가 및 지역에 대한 야채 세척 및 등급 분류 라인.

3-5t/h 토마토 및 서양 호박 세탁 건조 등급 라인이 터키로 배송됨

Taizy 공장은 최근 시간당 3~5톤의 용량을 갖춘 완전한 과일 및 야채 가공 라인을 터키에 수출했습니다. 고객은 대규모 과일 및 채소 농장을 보유하고 있으며 주로 토마토, 호박, 감자, 양파, 가지, 오이 및 피망을 가공하기 위해 라인을 구입했습니다. 라인의 가공 단계에는 세척, 건조, 등급 지정 및 포장이 포함됩니다.

터키 야채 가공 공장의 매개변수

| 목 | 매개변수 | 단위 |

| 1. 컨베이어 | 모델: TZ-1500 무게:160kg 힘: 1.1kw 크기: 1800*900*1200mm 전압: 415v/50hz, 3상 | 1세트 |

| 2. 버블 세척기 | 모델: TZ-8000 전압: 415v/50hz, 3상 무게:2000kg 힘: 10.5kw 크기: 8000*1500*1300mm 재질: 304 스테인레스 스틸 서핑 기능 추가, 원료 밀어 넣기 | 2세트 |

| 3. 헤어롤러 리무버 | 모델: TZ-2000 전압: 415v/50hz, 3상 무게: 1200kg 힘: 2.2kw 크기: 6000*1400*1200mm 롤러(소프트): 커버 포함 48개 | 1세트 |

| 4. 공기 냉각기 | 모델: TZ-3000 전압:415v/50hz, 3구 힘: 13.2kw 무게:2000kg 크기: 8000*1500*1600mm 재질: 304 스테인레스 스틸 팬 수: 16개 참고: 송풍기 기능을 추가하세요. | 1세트 |

| 5. 피킹 컨베이어 | 모델: TZ-2500 전압:415v/50hz, 3상 힘:0.75kw 무게:300kg 크기: 4000*700*900mm | 1세트 |

| 6.양방향 선별기 | 모델: TZ-250 분류 속도: 10000pcs/시간 전압:415v/50hz, 3상 정렬 간격:20-1500g 힘: 1.85kw 선택 기계 크기: 7400*1800*1200mm 지류 크기: 2100*800*1200mm 무게:1100kg 재질: 304 스테인레스 스틸 학년 수준: 10개 수준 정렬: 무게 기준 원재료 : 토마토, 감자, 양파, 고추 | 3세트 |

| 7. 분류기 | 모델: TZ-800 전압:415v/50hz, 3상 힘: 1.1kw 크기: 8000*1400*800mm 용량: 3-4t/h 정렬:직경별 원재료 : 오이(4레벨), 애호박(6레벨), 가지(6레벨) | 3세트 |

| 8. 바구니세탁기 | 모델: TZ-300 크기: 6100*1900*2300mm 전압:415v/50hz, 3상 무게:700kg 재질: 304 스테인레스 스틸 용량: 약 200-500pcs/h, 바구니가 더 깨끗하면 700-800pcs/h에 도달할 수 있습니다. 트레이 크기: 60*80cm; 60*40cm 추가 10pcs, 스프링클러 헤드 무료 참고 사항:1. SUS 3042 전체를 스프레이합니다. 주파수 변환 속도 조절3. 3개의 물탱크, 2개의 난방 물 탱크, 1개의 맑은 물 탱크4. 3개의 스테인리스 수도 펌프5. 탈수 fan6의 2 세트. 배수구와 오버플로 배출구가 스테인리스 배수구로 일체화되어 있습니다. | 1세트 |

| 9. 베개 포장기 | 모델: TZ-250 전압:415V,50hz,3문구 힘: 2.5kw 포장 속도: 40-230pcs/min 제품은 다음과 같습니다: 5-40mm 막 폭: ≤250mm 포장 높이: 5-60mm 크기: 3770*670*1450mm 무게:800kg 가격에는 다음이 포함됩니다: 질소 플러싱 시스템, 날짜 인쇄 기능 밀봉 블레이드: 3개 | 1세트 |

댓글 추가