The roti chapati making machine(tortilla maker) adopts an intelligent control system, which can produce buns continuously and uninterruptedly. This roti maker machine can not only produce chapati, but also roti, tortilla vegetable chapattis, spring roll, and other products. The commercial tortilla maker can intelligently control the output, capacity, and processing speed of chapatti. And through customization, it can produce different patterns of Rotis with different shapes and sizes. Therefore, it can meet different processing requirements according to customer needs.

Roti chapati tortilla making machine running video

Automatic roti chapati making machine parameters

| Model | Size | Voltage | Power | Capacity | Weight |

| TZ-120 | 1.6*0.6*1.2m | 220V/380V | 5-7KW | 120-200pcs/h | 150KG |

| TZ-700 | 5.2*0.8*1.4m | 380V | 20KW | 700-1200pcs/h | 420KG |

| TZ-1400 | 5.2*1.05*1.4m | 380V | 30KW | 1400-1800pcs/h | 480KG |

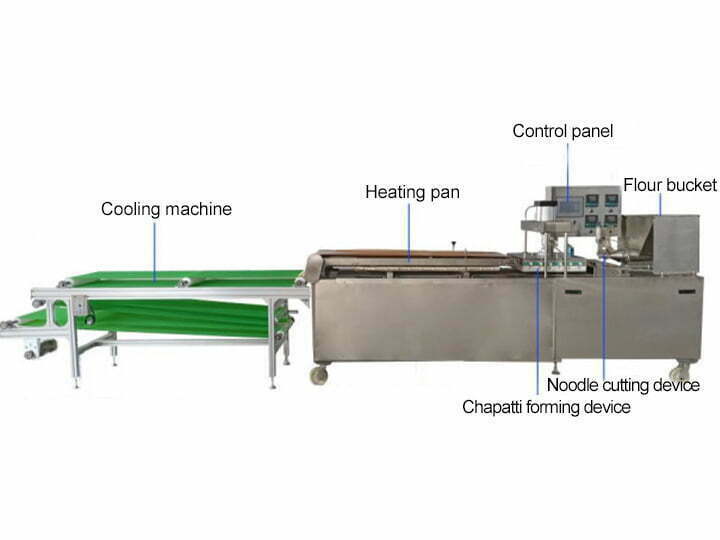

Commercial roti chapati making machine structure

The commercial roti chapati making machine is mainly composed of a flour bucket, control panel, noodle cutting device, chapatti forming device, bakeware, and other parts.

Flour bucket Flour bucket is mainly used for holding the dough. Therefore, it can equip with a dough mixer before the machine makes the dough.

Noodle cutting device The cutting device will cut the whole dough placed in the flour bucket into small pieces.

Chapatti forming device The cut dough falls onto the conveyor belt and then the conveyor belt transfers it to the forming device. Then the fully automatic chapatti maker machine’s forming device will press it into a round or square shape. By customizing the pressure plate’s size and pattern shape, it can produce different shapes and size’s chapatti.

Baking pan The shaped roti chapati is transported to the baking pan along the conveyor belt. The automatic roti maker machine, it distributes evenly the baking pans on the top and bottom of the machine. Therefore, the automatic roti chapati making machine can bake chapatti in all directions.

It generally equips with a cooling machine followed by the tortilla-maker. On the one hand, it can cool roti chapattis at high temperatures. On the other hand, it can collect chapattis to facilitate packaging.

Tortilla making machine working principle

The fully automatic tortilla making machine uses the principle of imitating handwork to make a tortilla. Put the reconciled noodles into the noodle bucket, the tortilla maker machine will automatically cut them into pieces, press, shape, and bake. The machine adopts an intelligent PLC control screen, which can adjust the size and weight of the sliced noodles at will. And it also can customize the shape, size, and pattern of the baking machine according to customer requirements. Its baking pan is a low-temperature baking pan, which can bake tortillas from low to high temperatures. So it is more conducive to the taste and quality of chapatti.

Characteristics of roti chapati maker machine

- The roti chapati maker machine controls by an intelligent control system, and it needs only one person to operate the machine.

- The automatic tortilla making machine has a wide range of production output and bread size, it can make two or even three roti chapattis at once

- It adopts the process of imitating hand-made cakes, with the baking process from low temperature to high temperature. So the taste of baked buns can be completely comparable to handmade chapattis.

- It also can adjust the size of the cutting noodles, the conveying speed, and the baking temperature through the control panel.

- The automatic roti chapati making machine has a wide range of applications. It not only can produce baked chapattis but also spring roll wrappers, vegetable cakes, and other products.

Automatic tortilla making machine operation steps

- The roti chapatti maker machine uses the principle of electric heating to bake chapattis. Turn on the power of the machine to preheat for about 15 minutes to bring the temperature to the set temperature.

- Use a dough mixer to mix water, flour, and other raw materials in a certain proportion. Then pour the dough into the dough bucket. The thickness of the batter will affect the thickness of the finished tortilla.

- Set specific parameters such as the size, pressure, and conveyor speed of the noodle block on the control panel. Save the set parameters to the database, and you can use them directly next time without repeating the settings.

- Start the run button, and the batter in the noodle bucket will automatically move to the noodle opening with the auger. Then the chapatti making machine will cut the noodles, transport them, press the cake and bake it according to the set parameters.

Roti chapati production line composition

The roti chapati maker machine also can also combine with the dough mixer, cooler, packaging machine, and other machines to form a chapatti production line. The automatic roti chapati production line will save the time of manual dough mixing, cake making, and packaging. It has greater production efficiency and can meet the requirements of mass production of chapattis.

Add Comment