Banana slicing machine scope of application

The multi-function banana slicing machine adopts the rotary knife plate cutting method, can process root vegetables including lotus root, cassava, potato (sweet potato), radish, cucumber, bitter melon, potato, and so on into chips, and has the characteristic of smooth cutting surface, uniform thickness, and size, fresh cutting surface, less damage caused to the fiber organization. At the same time, the machine is of high slicing efficiency, convenient operation, low energy consumption, high standard hygiene, and safety, it is the ideal equipment for agricultural product processing. The shape and size of the inlet hoppers of the cutter can be customized according to production requirements.

Banana slicing machine product structure

The multi-purpose cutter machine for root vegetables mainly composed of a rack, rotary cutter plate, transmission unit, motor, discharge port, etc., is suitable for slicing materials of medium volume and long cylindrical ship (such as lotus root, cassava, potato (sweet potato), radish. The interface of the machine and raw materials are all made of 304 stainless steel so as to ensure long-term service life without rust, and corrosion, therefore it is non-toxic, harmless, and meets the hygiene standard for food processing machinery.

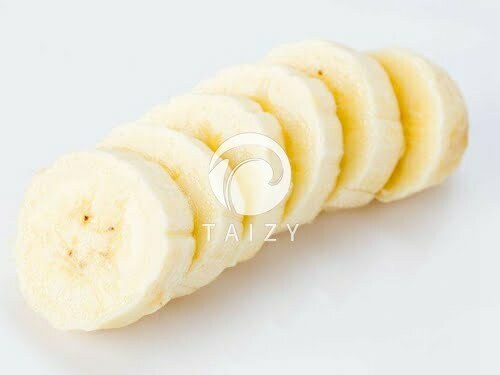

Banana slicing machine advantages

With fine function, the multi-functional slicer is of high slicing effect, and the cut is beautiful and neat, and burr, debris residue-free, and the slice thickness is uniform and is of good stability, continuous slicing can be achieved. The cutting and slicing machine is characterized by high efficiency, small size, less space occupation, low noise, ease of operation, energy-saving and safe, and fine design. The slicing thickness is more applicable than the average product in the market due to its adjustability according to production requirements.

Banana slicing machine operation method

Install the cutting equipment on the dry and ventilated ground before starting, then observe whether the specification of the cut vegetable is consistent with the product requirements, otherwise, the height of blade and rotary table shall be adjusted (or replaced), and the operation must be carried out after the adjustment is done. The thickness of the slice depends on the clearance between the blade and the rotary table.

Banana slicing machine installation and debugging

Place the machine on dry and ventilated horizontal ground before use to ensure smooth and reliable operation of the machine. Check all parts before use, to see whether the fasteners are loose during transportation, whether the switch and power line are damaged due to transportation, and whether there are foreign bodies in the hopper or material chamber or not. Check whether the power supply voltage is consistent with the set voltage of the slicing machine. Extend the line cord, ground the yellow and green cores of the cable with the grounding symbol tightly, and connect the other three cores (two for configuring a single-phase motor) to the disconnected leading out terminal of the open-type load switch (knife switch).

Open the front door before work to dial the rotary table to observe whether there is a knocking phenomenon between the plate and the blades, if there is, loose fastening bolt on the rotary table, and move the rotary table outward slightly, and then tighten the fastening bolt. Close the open-type load switch, and press the start button, to see whether the cutter is running in the right direction from the feeding port—the counterclockwise rotation is correct, otherwise, adjust the power line to make sure the cutter is running in the right direction. after that, run the un-load test, and with no parts abnormal the test running can be complemented.

Add Comment